Hydraulic type submarine pipeline connector

An underwater pipeline, hydraulic technology, applied in flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of labor and money, bumping of sealing steel ring, complicated and cumbersome, etc., and achieve convenient installation and operation. , convenient for hoisting, and the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiments and drawings.

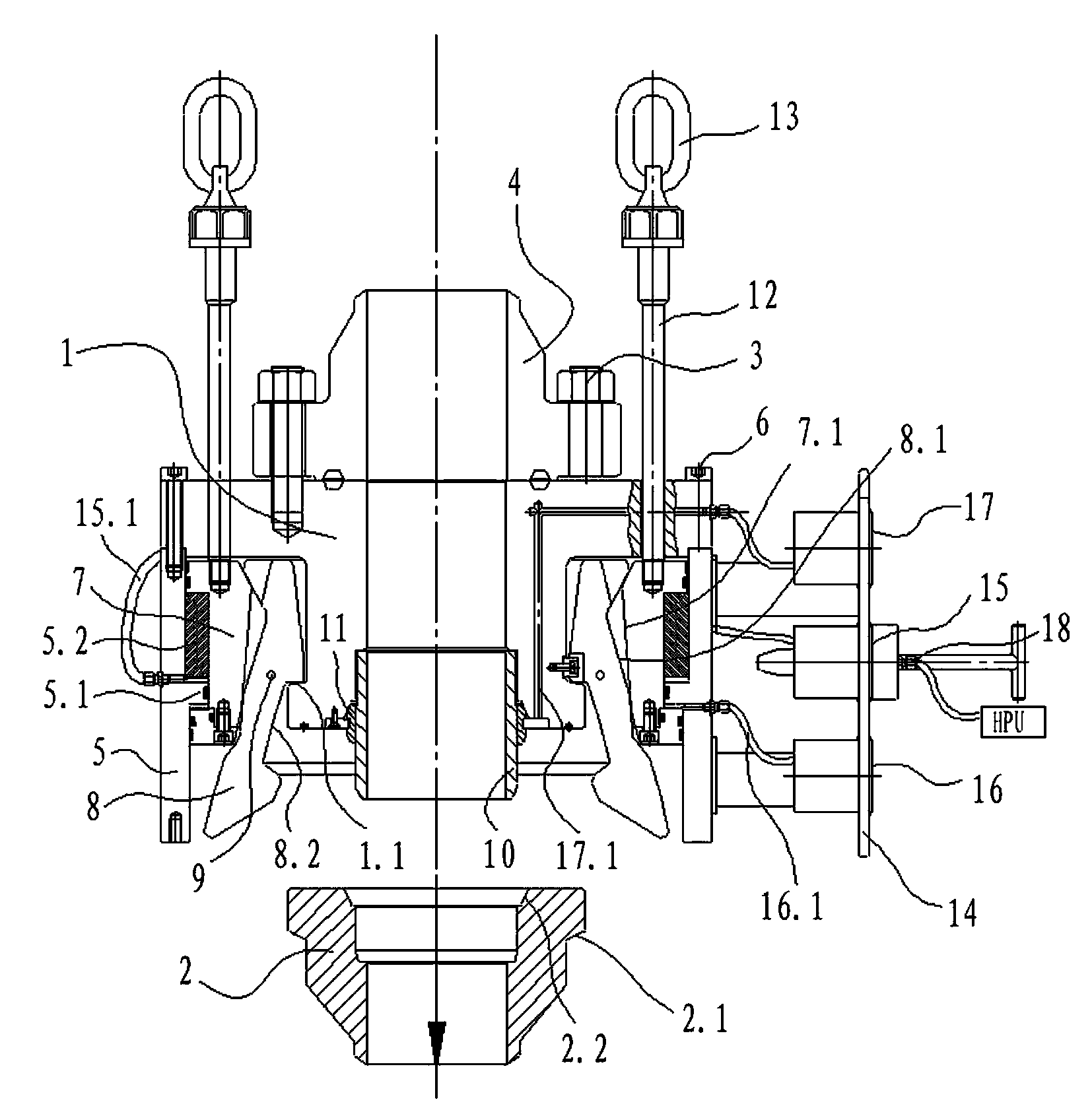

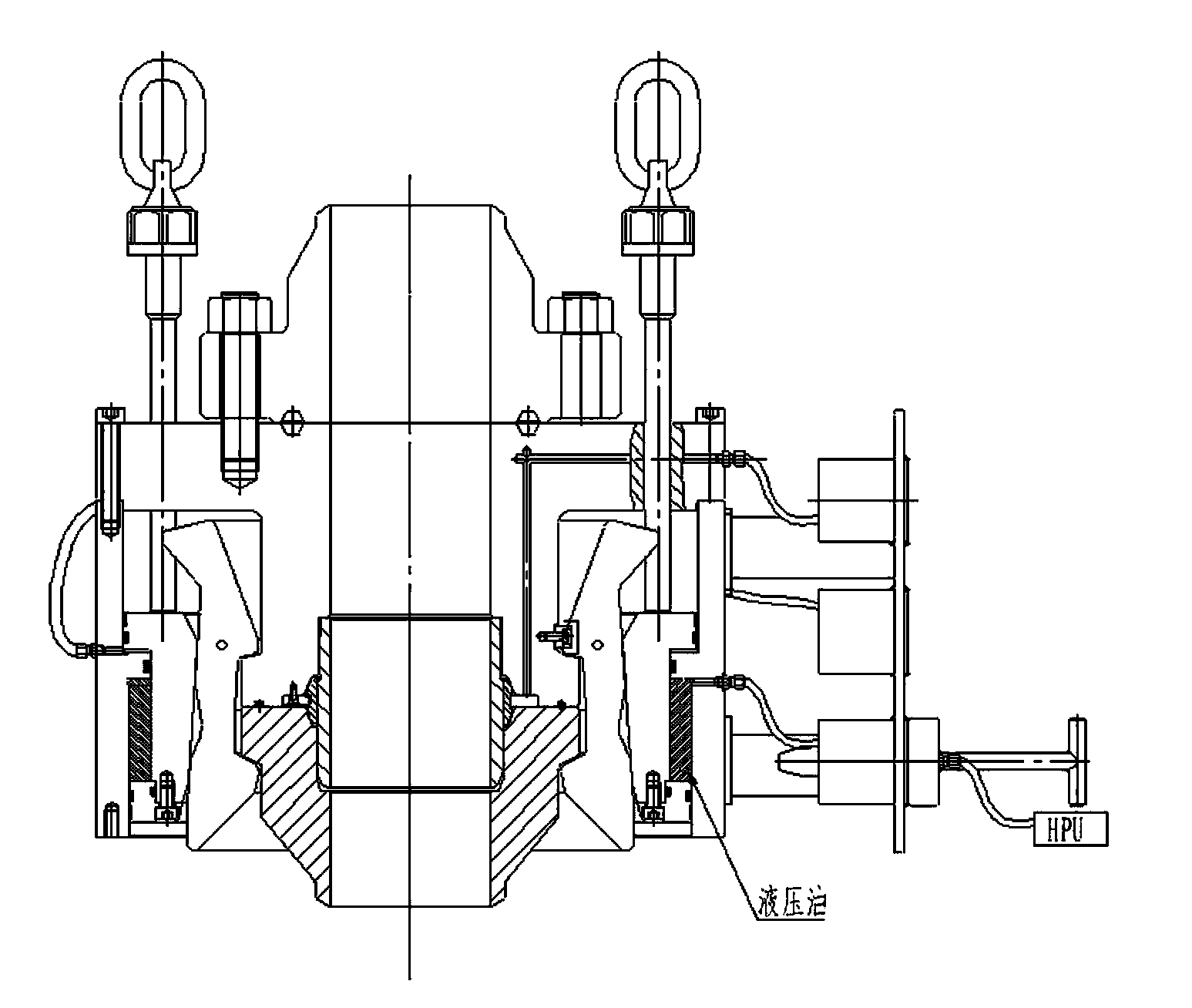

[0026] Referring to the drawings, the present invention includes an upper connecting flange 1 and a lower connecting flange 2. The upper end of the upper connecting flange 1 is fixedly connected to an upper flange 4 of one end connected to a submarine oil pipeline (not shown in the figure) through bolts and nuts 3, and one end of the lower connecting flange 2 is directly fixedly connected to another submarine oil pipeline Road (not shown in the figure). If the upper connecting flange 1 and the lower connecting flange 2 are fixedly connected, the hole in the pipeline should be airtight.

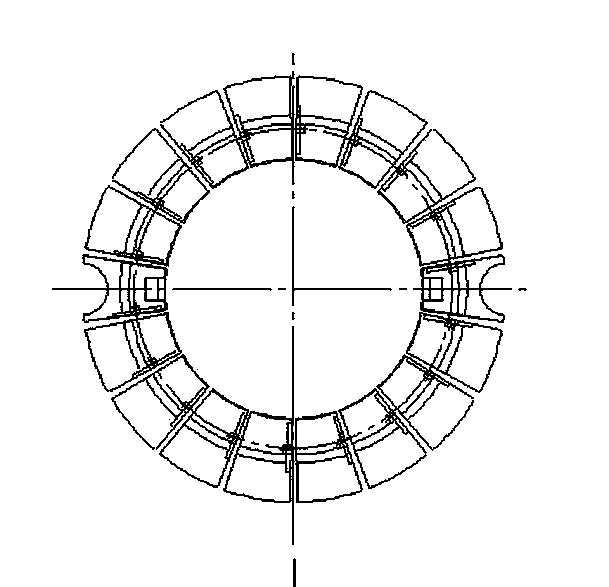

[0027] In the present invention, a hydraulic cylinder body 5 is sleeved outside the upper connecting flange 1 and fixedly connected by screws 6. The hydraulic cylinder body 5 has a built-in annular piston 7 that can slide up and down along the inner wall of the hydraulic cylinder body 5. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com