Novel U-shaped pipe bundle type heat exchanger

A technology of U-shaped tubes and heat exchangers, which is applied in the field of new U-shaped tube bundle heat exchangers, can solve the problems of less arrangement of heat exchange tubes, low utilization rate of tube sheets, and unfavorable heat transfer, etc., so as to improve utilization rate, Improve the effect of short circuit phenomenon and improve heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

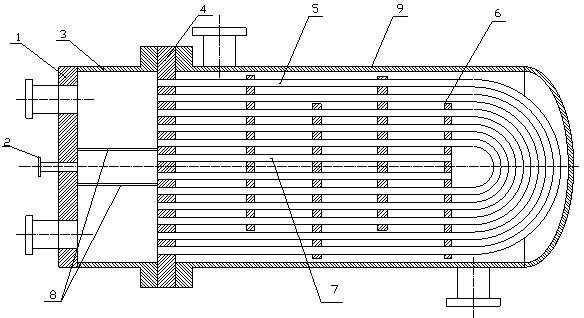

[0020] like Figure 1 As shown, a new type of U-shaped tube bundle heat exchanger includes a guide tube 3, a tube box end cover 1 and a tube plate 4 respectively arranged at the left end and the right end of the guide tube 3, and the right side of the tube plate 4 is fixed There is a U-shaped tube bundle 5 communicating with the guide cylinder 4, and the right side of the tube plate 4 is also connected with a housing 9 that accommodates the U-shaped tube bundle 5 therein, and the housing 9 is also provided with deflectors in parallel. The plate 6 and the guide cylinder 3 are separated by a certain distance at the junction of the inlet and outlet of the U-shaped tube bundle 5. Separate partitions 8 are arranged above and below, and the partitions 8 extend from the tube box end cover 1 to the tube plate 4. In the middle of the tube sheet 4, there is also a straight tube 7 that extends rightward into the innermost cavity of the U-shaped tube bundle 5 and reaches the rightmost baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com