Optimal control method and system for scr denitrification system

A technology of system optimization and control method, applied in the field of SCR denitration system, can solve problems such as affecting the control efficiency and rationality of SCR denitration system, and unable to optimize control of system real-time parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

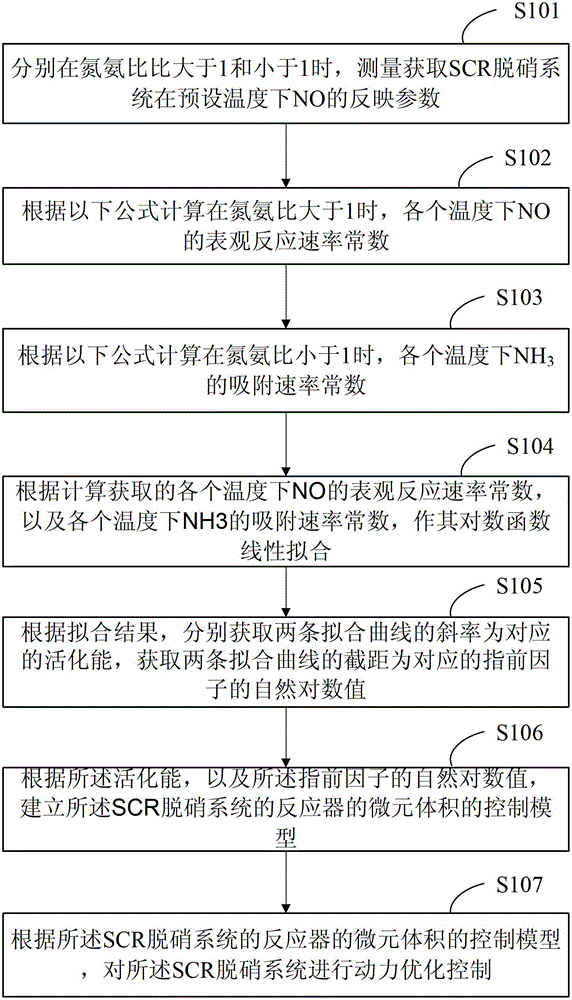

[0075] see figure 1 , figure 1 It is a schematic flow chart of the optimal control method for the SCR denitrification system of the present invention.

[0076] The method for optimizing the control of the SCR denitrification system comprises the following steps:

[0077] S101, when the nitrogen-ammonia ratio is greater than 1 and less than 1, measure and obtain NO reflection parameters of the SCR denitrification system at a preset temperature;

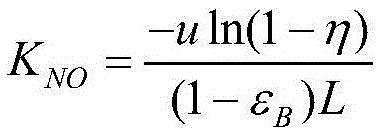

[0078] S102, calculate the apparent reaction rate constant K of NO at each temperature when the nitrogen-ammonia ratio is greater than 1 according to the following formula NO :

[0079] K N O = - u l n ( 1 - η ) ( 1 - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com