Method for positioning angle of wafer ring assembly and mechanism for implementing the method

An angle positioning and carrier ring technology, which is applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve problems such as easy failure of image recognition, high cost and time-consuming machine design and construction, and achieve positioning Fast and easy to implement, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

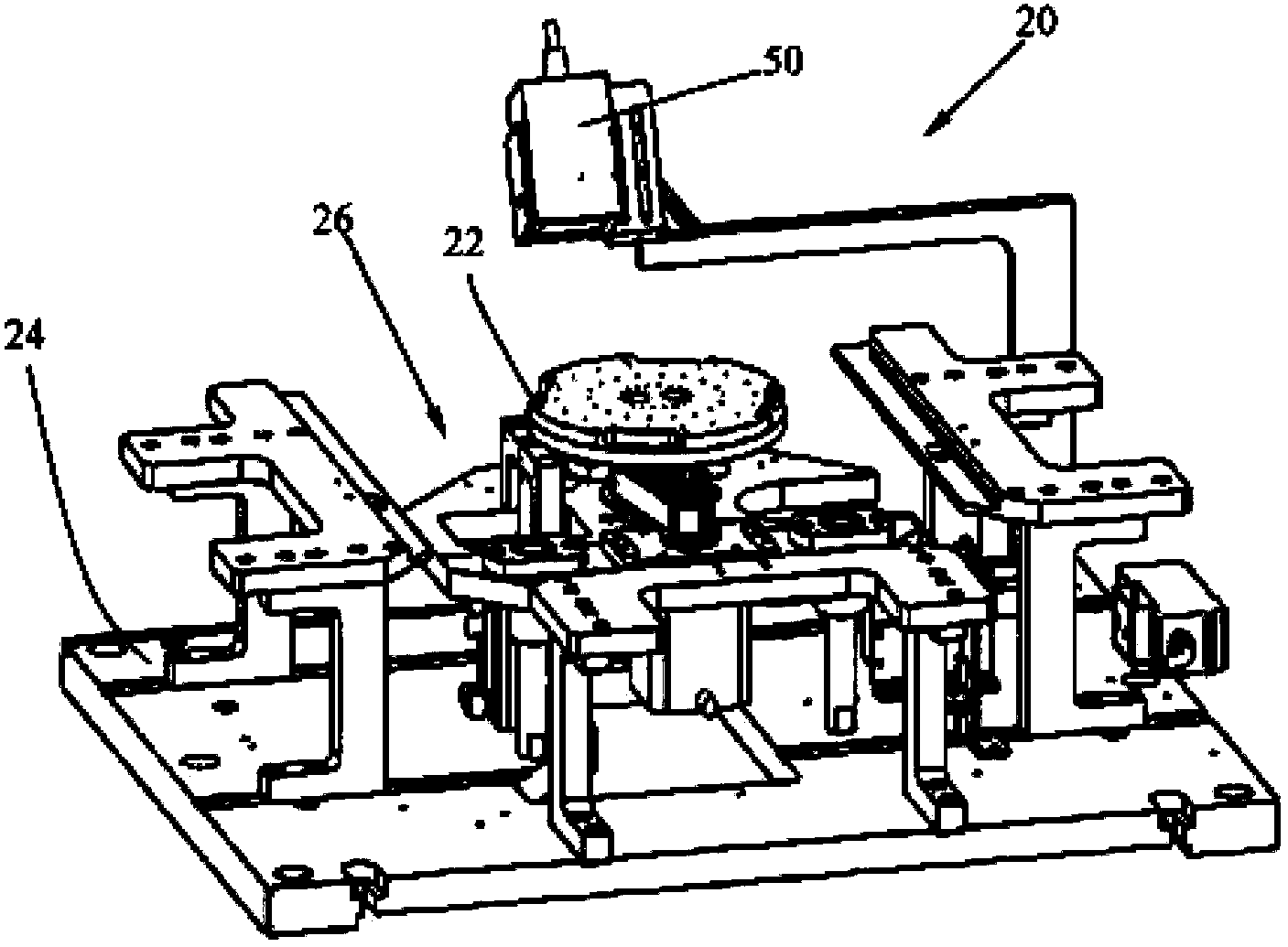

[0030] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

[0031] First of all, it must be noted that in the embodiments disclosed below and the accompanying drawings, the same reference numerals represent the same or similar elements.

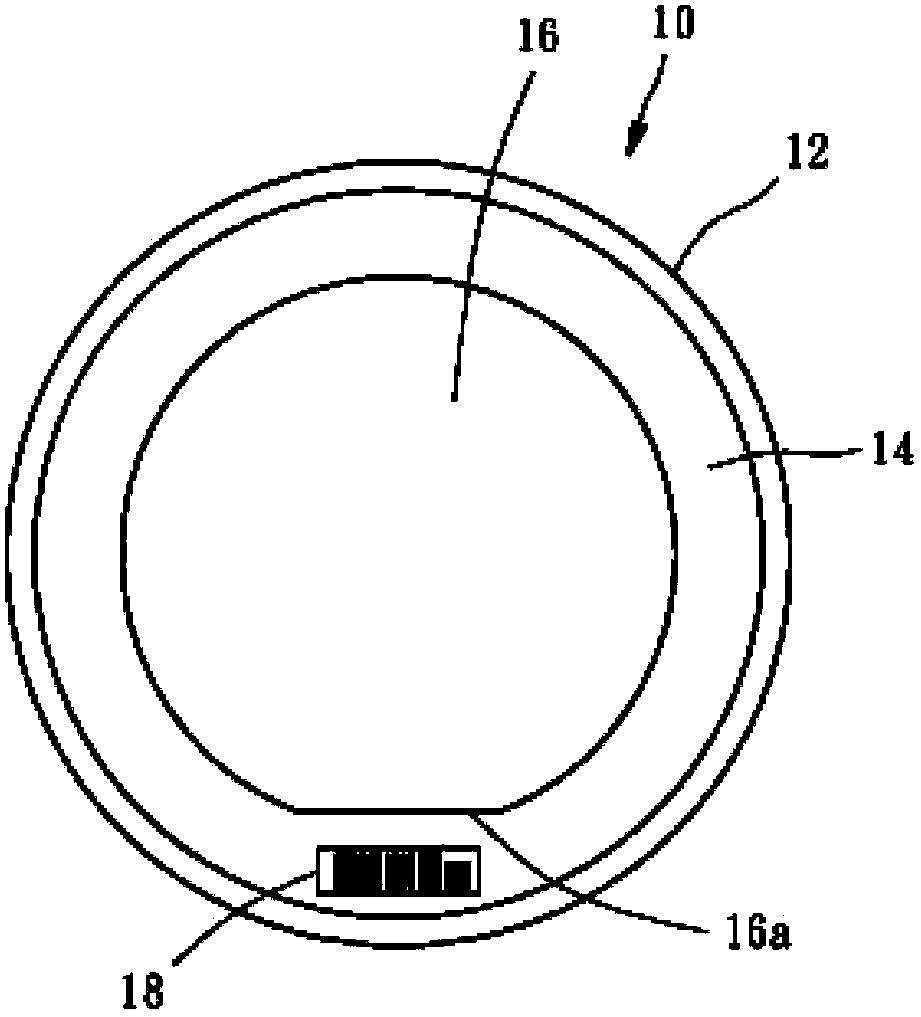

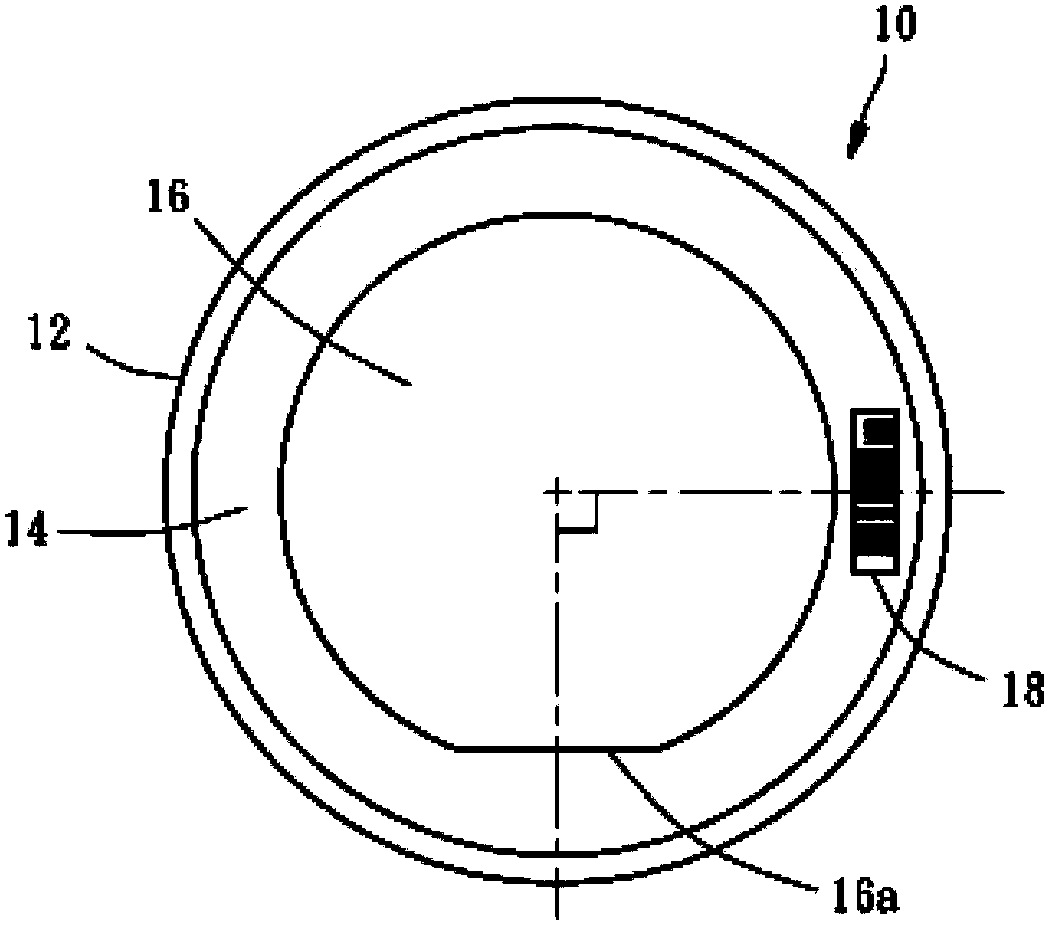

[0032] see figure 1 , figure 1 A wafer carrier ring assembly 10 suitable for the angular positioning method of the wafer carrier ring assembly provided by a preferred embodiment of the present invention is shown. The wafer carrier ring assembly 10 is made of a circular plastic ring 12. A light-permeable film 14 such as blue film (blue tape), a wafer 16 attached to the light-transmittable film 14 and cut (dicing), and a light-transmissive film 14 attached to the light-transmissible film 14. The non-transparent positioning label 18 on the frame is formed. Wherein, the periphery of the transparent film 14 is fixed on the ring 12 and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com