Magnetic pole position detecting device

一种磁极位置、检测装置的技术,应用在起动的装置、交流电动机角单轴角速度控制、电气元件等方向,能够解决实用的观点不理想、检测精度降低、无法正确检测磁极位置等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

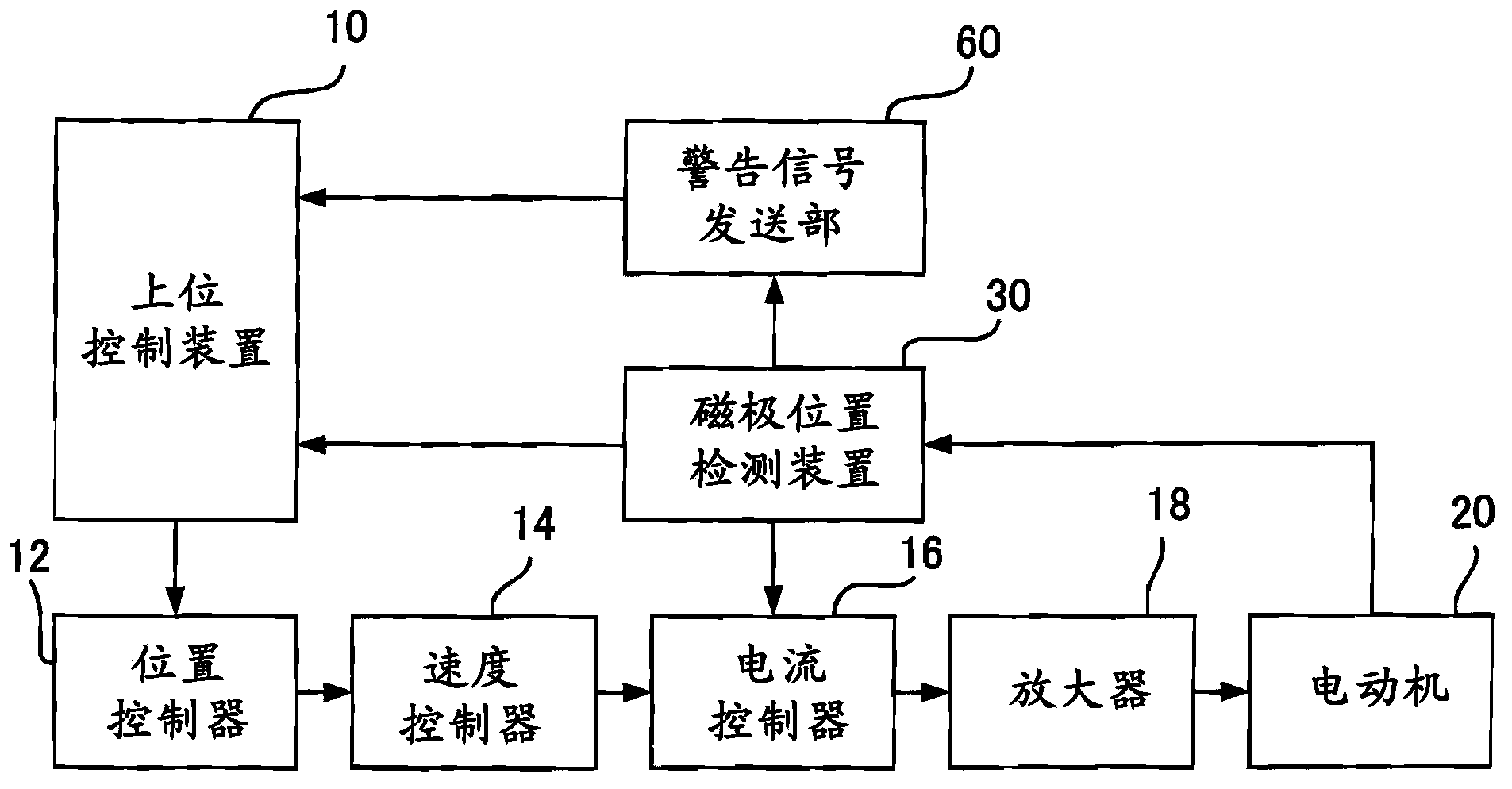

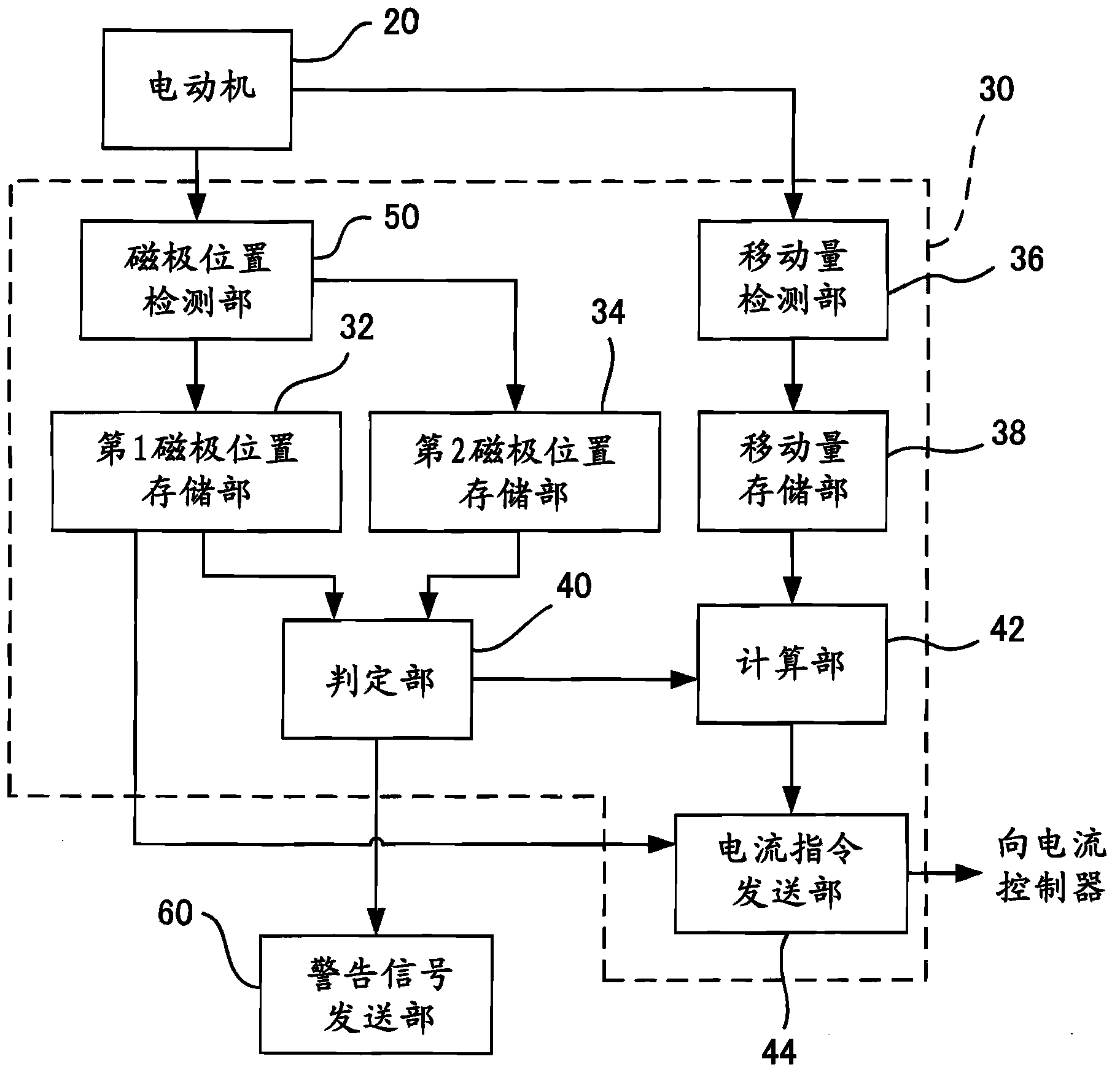

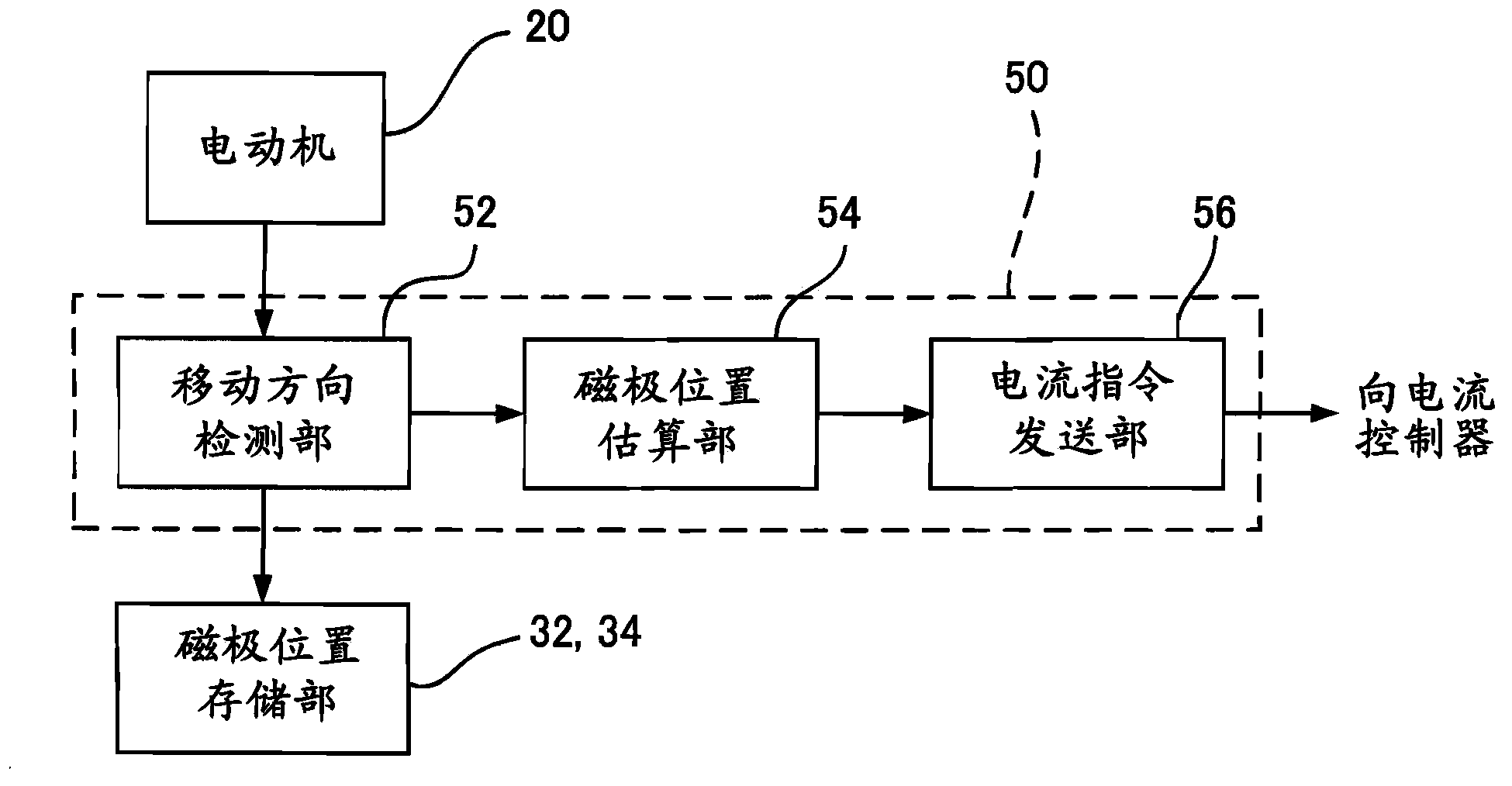

[0015] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. figure 1 It is a block diagram which shows the structure of the control system which can apply this invention. like figure 1 As shown, the control system includes a host controller 10 , a position controller 12 , a speed controller 14 , a current controller 16 , an amplifier 18 , a motor 20 , a magnetic pole position detection device 30 , and a warning signal transmitter 60 . The motor 20 is a known permanent magnet synchronous motor including a rotor provided with permanent magnets and a stator provided with coils. Sensors such as encoders (not shown) for detecting rotor motion (position and speed) are mounted in the motor 20 .

[0016] The host controller 10 controls the operation of the electric motor 20 used for the machine tool or the like. The host control device 10 issues a position command for controlling the operation of each axis of the motor 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com