wiper blade with adapter unit for articulation on wiper arm

A transfer unit, wiper blade technology, applied in the direction of vehicle cleaning, vehicle maintenance, transportation and packaging, can solve the problems of undesired wind noise, large structure height, etc., to achieve cost economy, low structure height, large guide effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

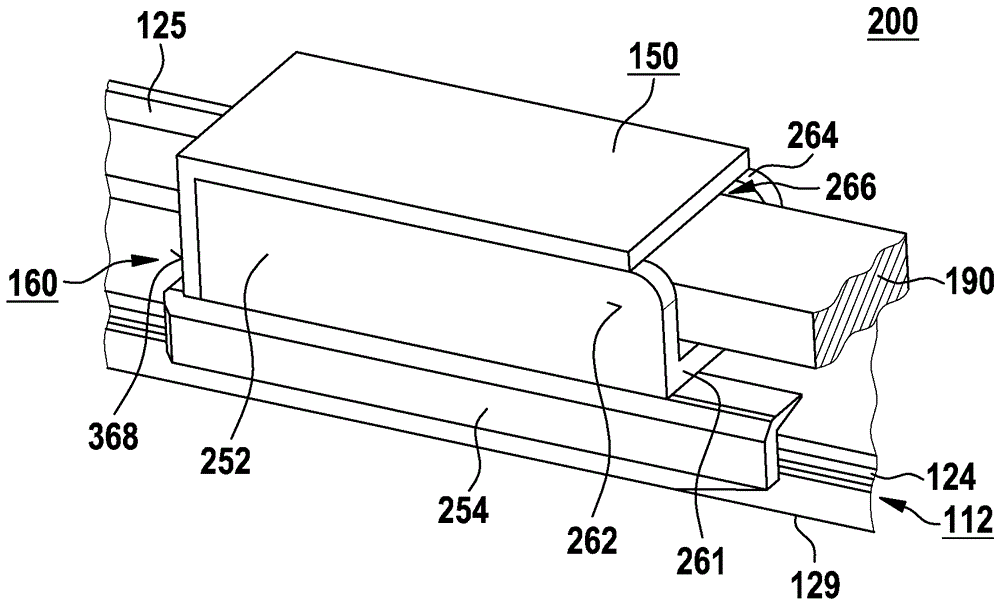

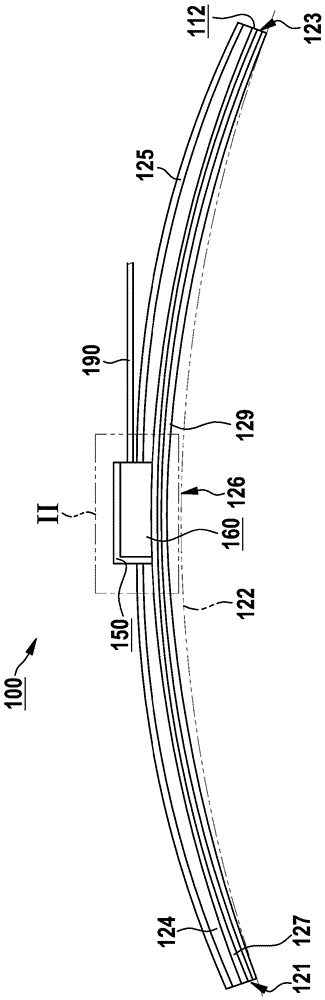

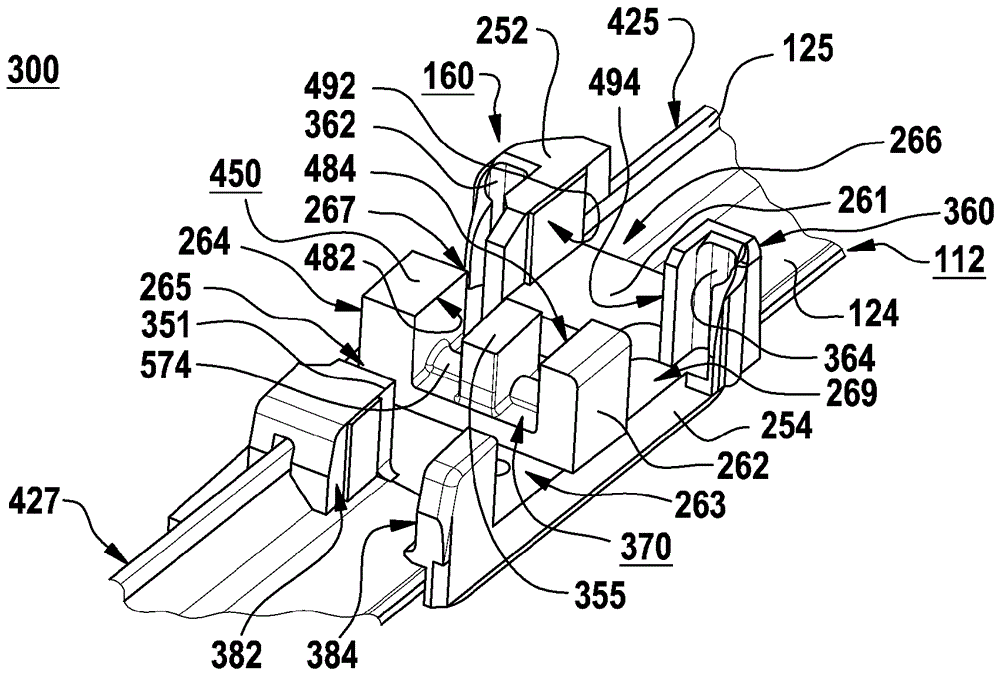

[0032] According to one specific embodiment, the wiper blade 100 is designed as a flat rod, ie the wiper strip 112 has lateral longitudinal grooves, which are formed, for example, on the back strip 124 and in which two support rails, Spring rails are preferred. As an alternative thereto, the wiper strip 112 can be designed as a hollow profile with an approximately central longitudinal channel, for example provided in the back strip 124 , in which a separate support rail is arranged.

[0033] Attached to the wiper strip 112 is an adapter unit 160 , which is covered by an optional cover-like fastening element 150 and serves to articulate the wiper strip 112 to a wiper arm 190 with which the wiper arm can be guided. The water blade 100 is intended to wipe over a window pane 122 indicated by a dotted line, for example a motor vehicle window pane. The adapter unit 160 is preferably fastened permanently to the wiper strip 112 , for example at least partially in an interruption or r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com