Automatic sugar cane peeler

A sugarcane and peeling technology, applied in the peeling of vegetables or fruits, food science, applications, etc., can solve the problems of low efficiency, difficulty in cleaning sugarcane skins, and fragile tools of power devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

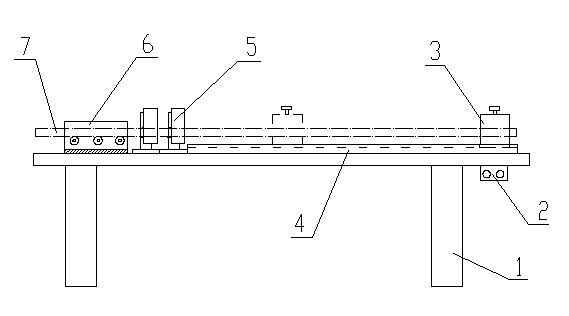

[0024] see figure 1 , The present embodiment is an automatic sugarcane peeler, which consists of a base 1, a clamping device 3, two pairs of cutters positioned on the same straight line, and a guide mechanism 6.

[0025] Control switch 2 is equipped with on the front side of support 1, power socket is equipped with at the bottom position of support 1, and two parallel linear guide rails 4 are housed on the support.

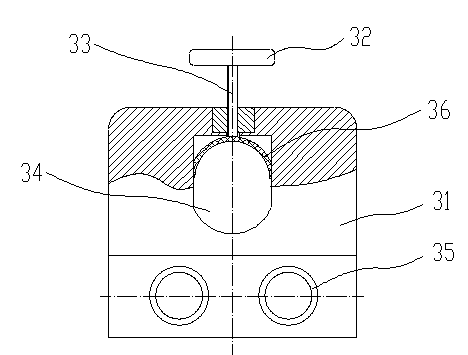

[0026] The clamping device 3 includes a clamping seat 31, and the lower part of the clamping seat 31 is provided with through holes that cooperate with the two linear guide rails 4, such as figure 2 As shown, a linear motor 35 is provided in the through hole, a sugarcane hole seat 34 is provided at the upper part of the clamping seat 31, and a screw hole is provided at the middle upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com