Precision milling cutter and processing method thereof

A milling cutter, precision technology, applied in the field of processing tools, can solve the problems of milling cutters prone to breakage, cutting edge not sharp enough, and reduce processing efficiency, so as to achieve smooth chip discharge, improve milling cutter strength, and reduce cutter breakage rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

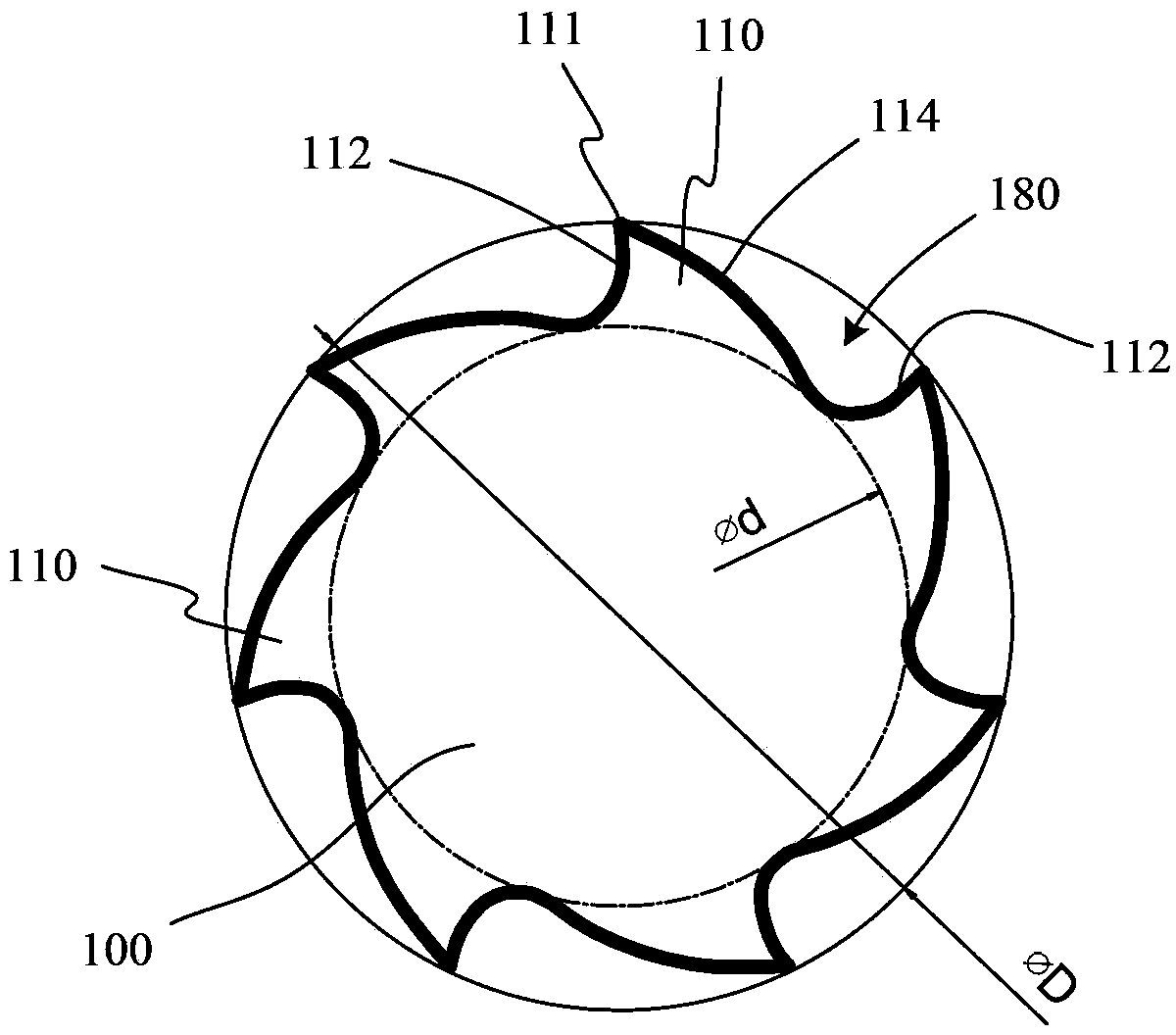

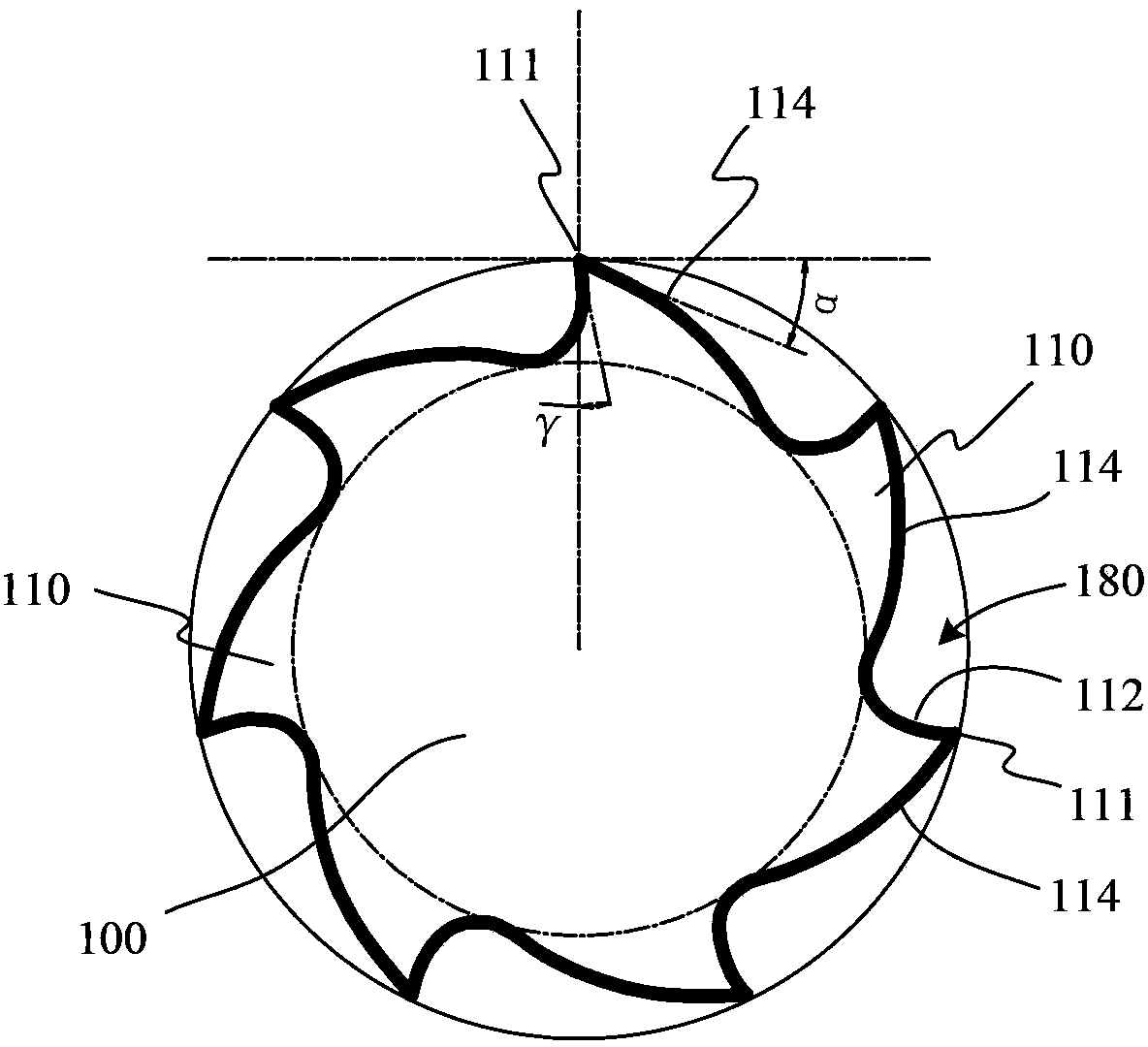

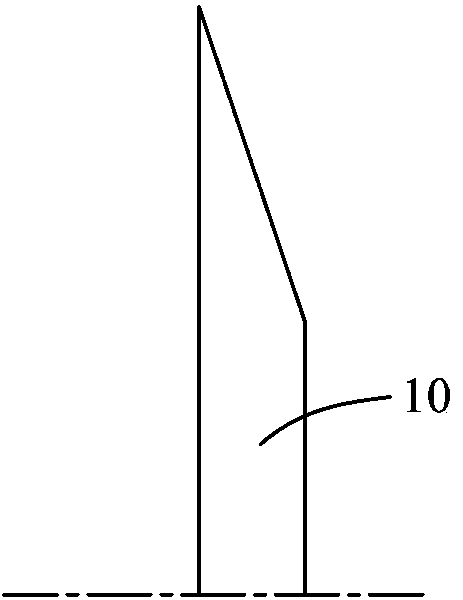

[0029] Such as Figure 4-6 As shown, the present invention is described with a multi-edge chipbreaker type precision milling cutter, which includes: a cutter body 100 and a plurality of cutter teeth 110 arranged on the outer periphery of the cutter body 100; wherein the cutter teeth 110 include a cutting edge 111, a front cutter Surface 112 and flank surface 114; a flat section is arranged between the cutter teeth 110, forming a flat bottom surface 117 on the cutter body 100, and the rake surface 112 and the cutter surface 114 between adjacent two cutter teeth 110 And the flat bottom surface 117 constitutes the wall surface of the spiral groove 180 respectively, the flat bottom surface 117 makes the bottom of the spiral groove 180 between the knife teeth 110 form a relatively flat bottom surface, the flat bottom surface 117 and the spiral groo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com