Automatic electric welding machine

An automatic electric welding and welding torch technology, applied in arc welding equipment, welding equipment, welding equipment and other directions, can solve the problems of workers not being able to work in electric welding for a long time, waste physical effort, etc., and achieve the effect of reducing manpower, improving work efficiency, and high welding precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

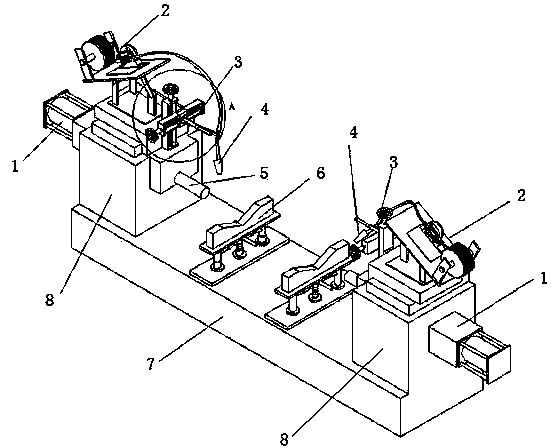

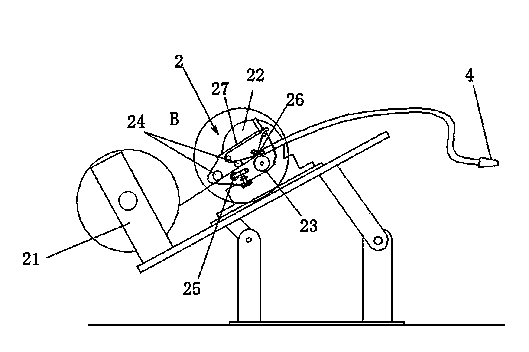

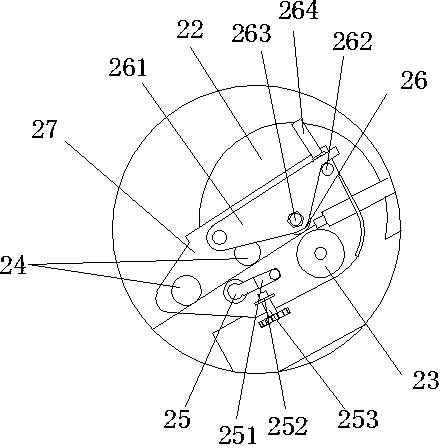

[0020] Example 1, such as Figure 1-2 As shown, an automatic electric welding machine includes a platform 7, and an electric welding device 8 is symmetrically arranged on the left and right ends of the platform 7. The electric welding device 8 includes a cylindrical ejector rod 5, and the front section of the ejector rod 5 is provided with a central hole for sleeve Connected to the workpiece, it also includes a driving device 1 that drives the ejector rod 5 to move horizontally or rotate. The ejector rods 5 at both ends bear against the two ends of the workpiece, and then rotate the workpiece after being tightened. There is also a welding torch 4, a wire feeding device 2 and a welding torch mobile platform 3 for automatically transporting the welding wire for the welding torch 4; the welding torch 4 is connected to the welding torch mobile platform 3. The wire feeding device 2 includes a wire stand 21, a motor 22, a bottom plate 27 connected to the motor 22, a driving wheel 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com