Piezoelectric type jet nozzle device for micro-droplet generation

A piezoelectric and micro-droplet technology, which is applied in printing and other directions, can solve the problems of limiting the jetting frequency of piezoelectric jetting devices, taking a certain amount of time to arrive, and the high cost of commercialized jetting heads, so as to reduce jetting waiting time and facilitate The effect of production and improvement of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

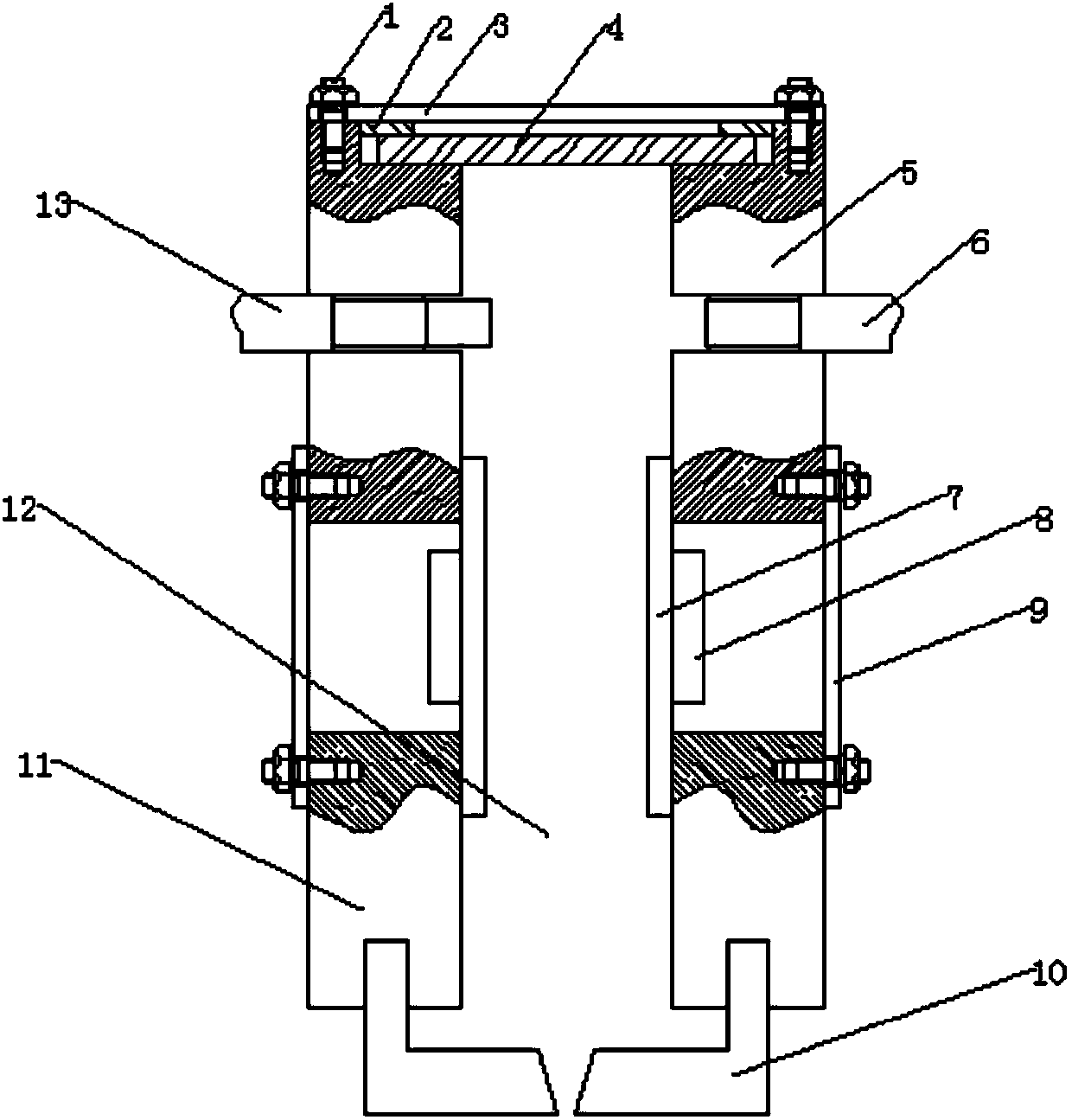

[0027] Such as figure 1 As shown, a novel piezoelectric nozzle device for micro-droplet generation, including: an injection body with an injection chamber 12, a nozzle 10 located at one end of the injection body, an injection power source, a pressure detection mechanism, and a pressure wave attenuation mechanism Wait.

[0028] The injection cavity 12 is a cylindrical structure, including an upper cavity 5 and a lower cavity 11; the upper cavity 5 and the lower cavity 11 are fixed to each other by a coaxial annular connecting plate 9, that is, the top of the connecting plate 9 is connected to the The bottom of the upper cavity 5 is fixed, and the bottom end of the connecting plate 9 is fixed to the top of the lower cavity 11 by studs. There is a gap for placing the piezoelectric ceramic ring 8 between the two fixed ends of the upper cavity 5 and the lower cavity 11 . The top of the upper chamber 5 is provided with a mounting groove for arranging the piezoelectric diaphragm 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com