A collapsible lift conveyor

A technology of a feeding car and a folding device, which is applied in the field of lifting and feeding car, can solve the problems of inconvenient transportation of the engine feeding car, difficult transportation at different heights, large storage space, etc., and achieves a simple structure, convenient transportation and high processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

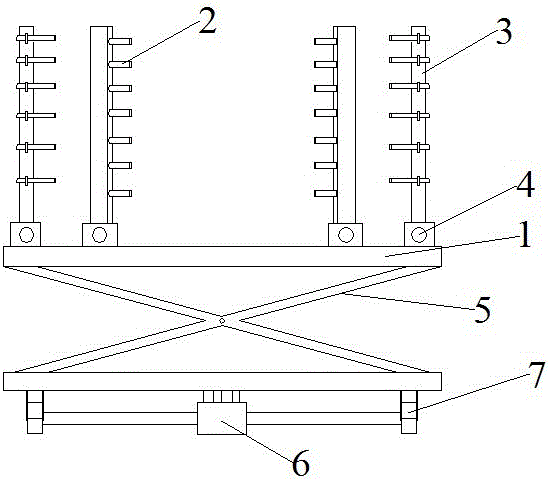

[0025] Such as figure 1 Shown, a kind of foldable lifting conveying vehicle comprises square base 1, motor 6, and square base 1 upper surface is provided with four vertical plates 3; One side of vertical plate 3 is provided with transverse short plate 2, vertical A hinge 4 is provided between the board 3 and the square base 1; a folding device 5 is provided at the bottom of the square base 1; the front and rear ends of the folding device 5 have a symmetrical structure, and the front and rear ends are two cross-connected activities plate; the lower part of the folding device 5 is also provided with a roller 7; a transmission device is provided between the roller 7 and the motor 6.

[0026] In addition, the four vertical plates 3 are arranged in a parallelogram on the square base 1 . Among them, there are 6 short plates 2 on the two vertical plates 3, which are connected by welding; the short plates 2 on the other two vertical plates 3 are 7 pieces, which are connected by bolt...

Embodiment 2

[0029] Same as embodiment 1, the difference is that the number of short plates on the vertical plate 3 is 6, and all of them are connected by welding.

Embodiment 3

[0031] Same as embodiment 1, the difference is that the number of short boards on the vertical board 3 is 8, all of which are connected by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com