Automobile front longitudinal beam end plate assembly, front end assembly and automobile

A front longitudinal beam and beam assembly technology, applied in the upper structure sub-assembly, vehicle parts, upper structure, etc., can solve the problems of high workload of front-end assembly, high R&D cost, waste, unusable front-end assembly, etc. Achieve the effects of reducing change costs, increasing utilization, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

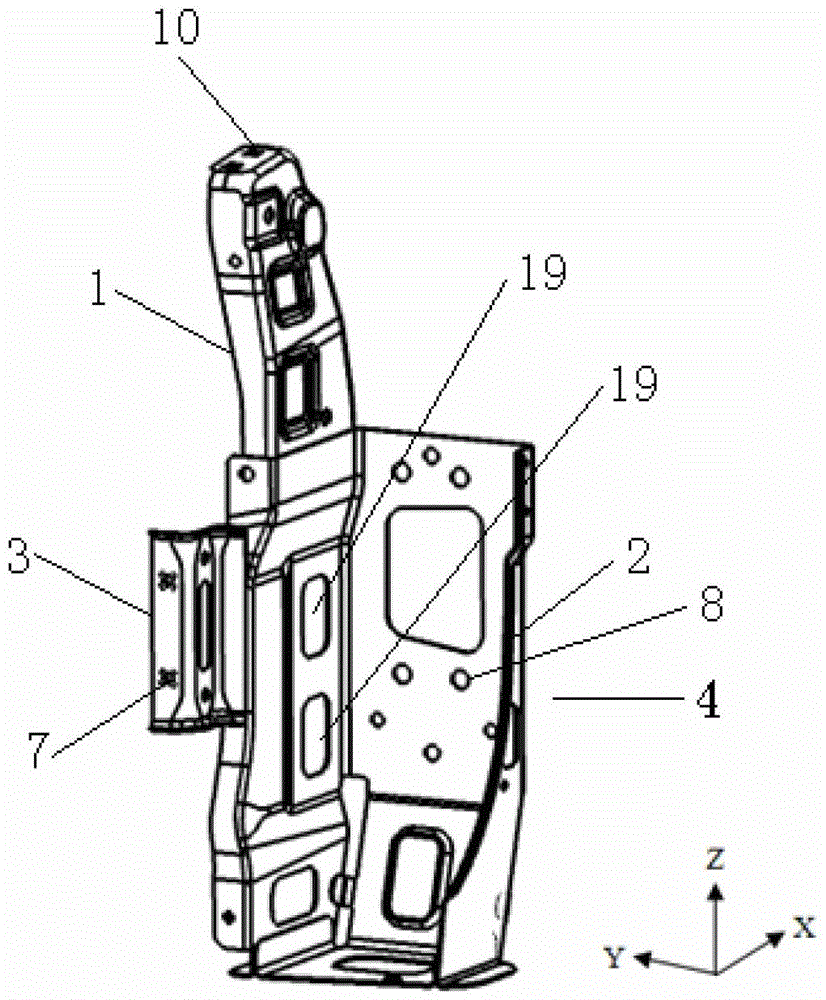

[0028] Such as figure 1 As shown, the present embodiment provides a front longitudinal beam end plate assembly 4 of an automobile, the automobile includes a water tank upper beam 9 and a front bumper beam assembly 6, and the front longitudinal beam end plate assembly 4 includes a front longitudinal beam The upper body 1 of the end plate and the lower body 2 of the front longitudinal beam end plate, the upper body 1 of the front longitudinal beam end plate is connected with the lower body 2 of the front longitudinal beam end plate, and the upper body 1 of the front longitudinal beam end plate is used for Connect the upper beam 9 of the water tank.

[0029] Such as image 3 , 7 , 8, in this embodiment, the lower body 2 of the front longitudinal beam end plate is specifically used to connect the water tank lower beam 5 and the front bumper beam assembly 6. The joint of the lower body 2 of the front longitudinal beam end plate and the upper body 1 of the front longitudinal beam...

Embodiment 2

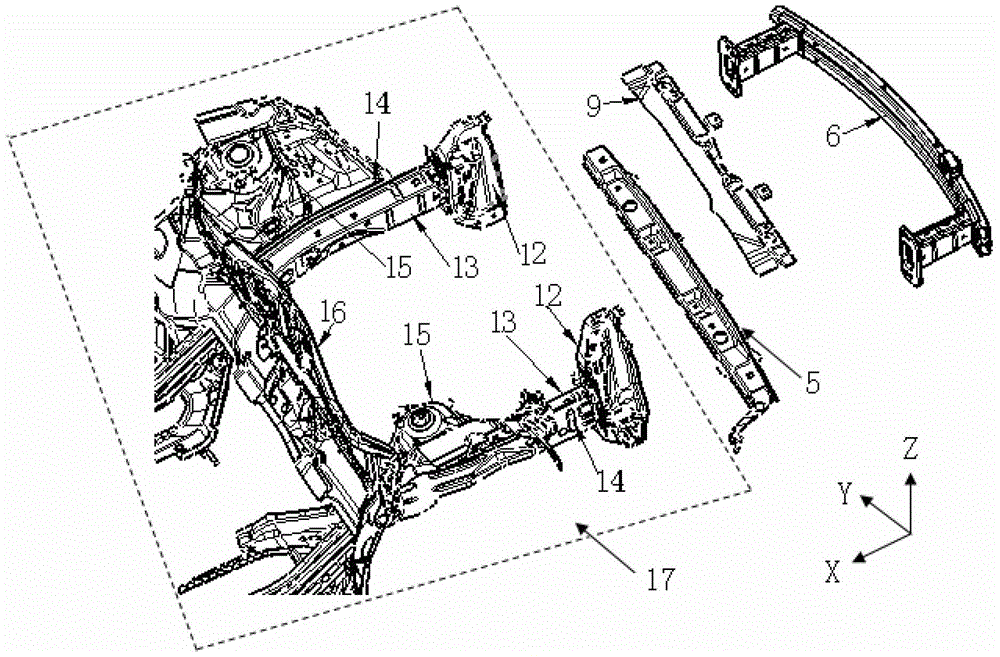

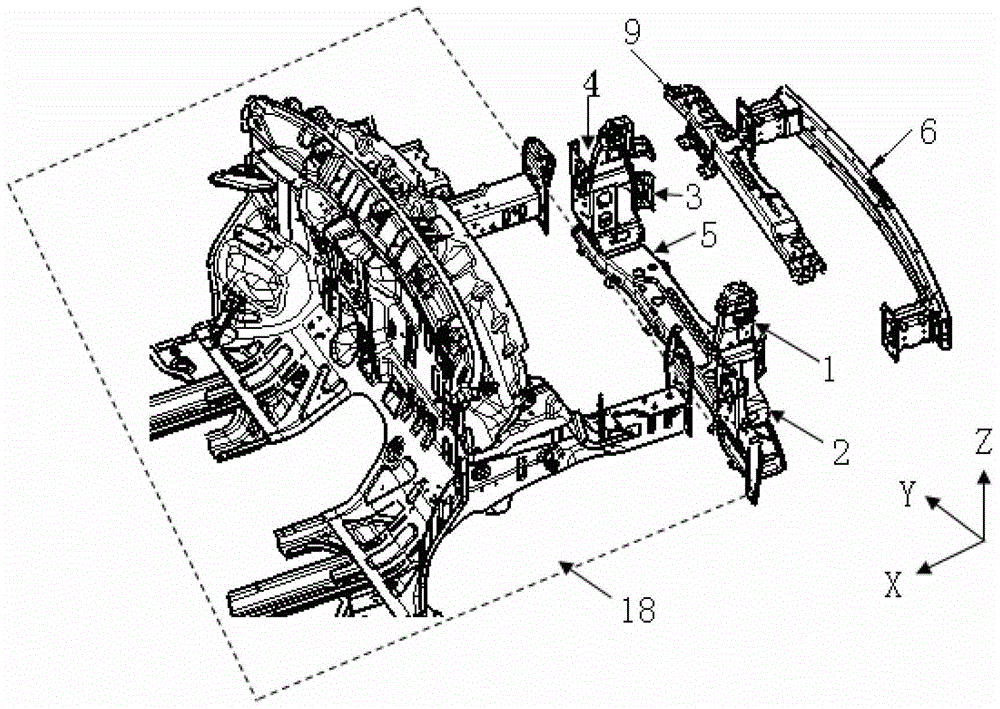

[0035] Such as Figure 4~6As shown, the present embodiment provides an automobile front end assembly including the automobile front longitudinal beam end plate assembly 4 in Embodiment 1, the automobile front end assembly also includes the water tank lower beam 5, and the front longitudinal beam end plate The lower body 2 includes the lower body of the left front longitudinal beam end plate and the lower body of the right front longitudinal beam end plate. connect. And after the two ends of the water tank lower beam 5 are respectively connected with the lower body of the left front longitudinal beam end plate and the lower body of the right front longitudinal beam end plate, the front end assembly is a U-shaped front end assembly.

[0036] Such as figure 2 As shown, the front end assembly of the automobile in the prior art includes: the water tank lower crossbeam 5, the water tank upper crossbeam 9, the front longitudinal beam end plate 12, the front bumper crossbeam assemb...

Embodiment 3

[0051] This embodiment provides an automobile, including the front end assembly of the automobile in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com