Special lifting device for shaft roller

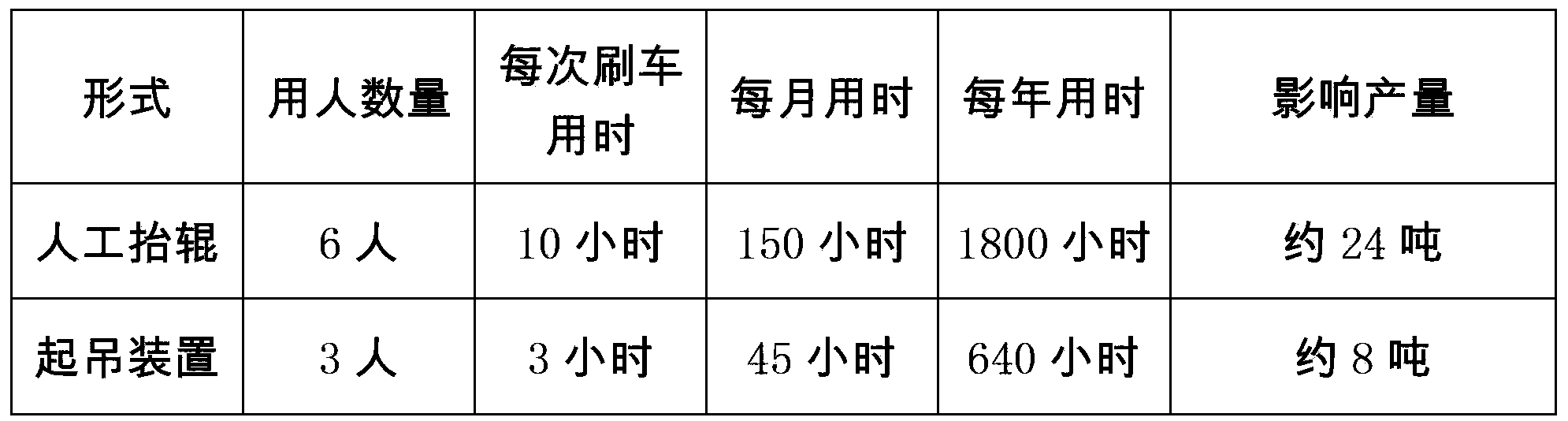

A hoisting device and shaft-roller technology, which is applied in hoisting devices, hoisting equipment braking devices, cranes, etc., can solve problems such as high labor intensity, low production efficiency, and poor product quality, and achieve flexible spreader angles and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

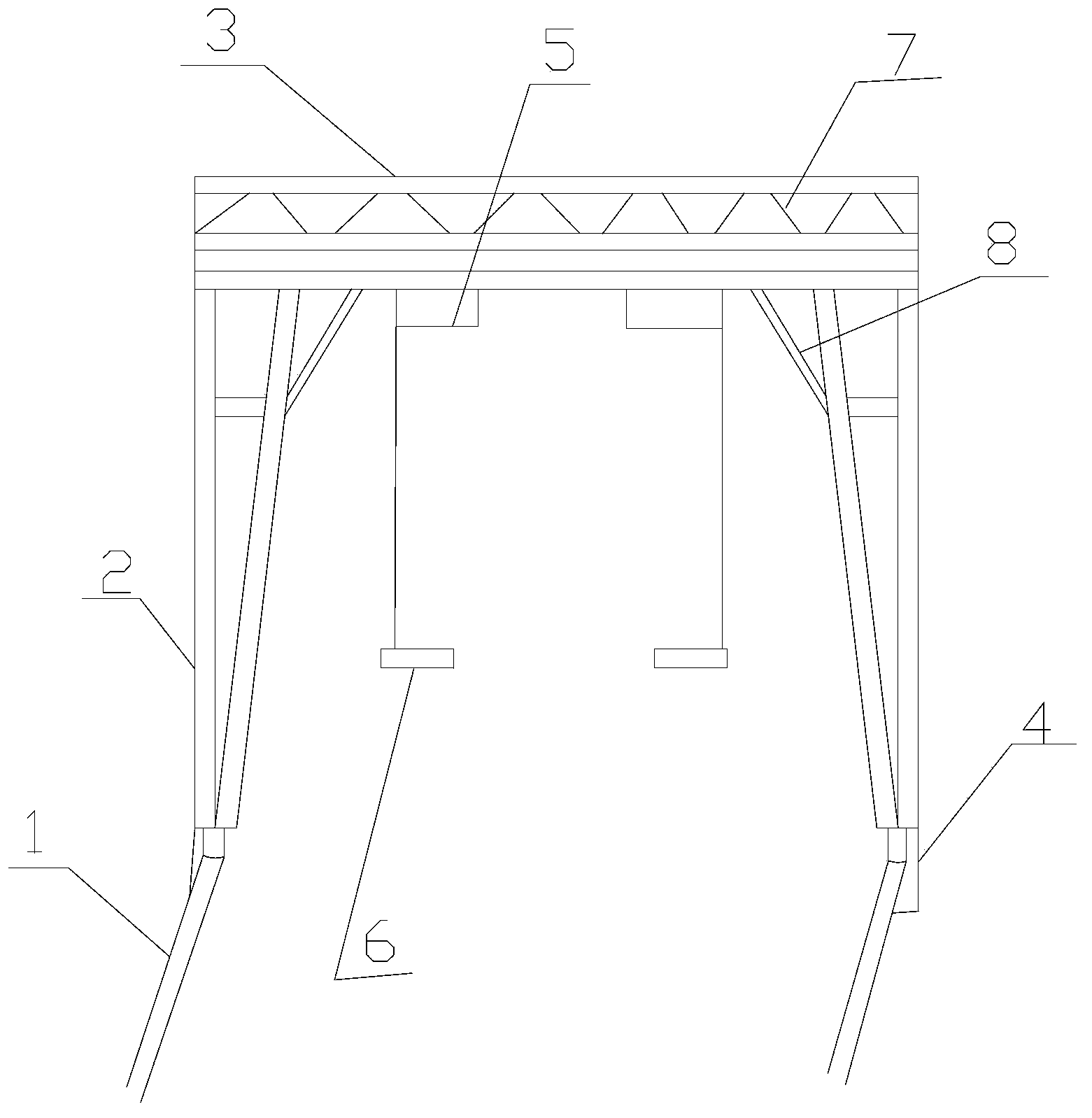

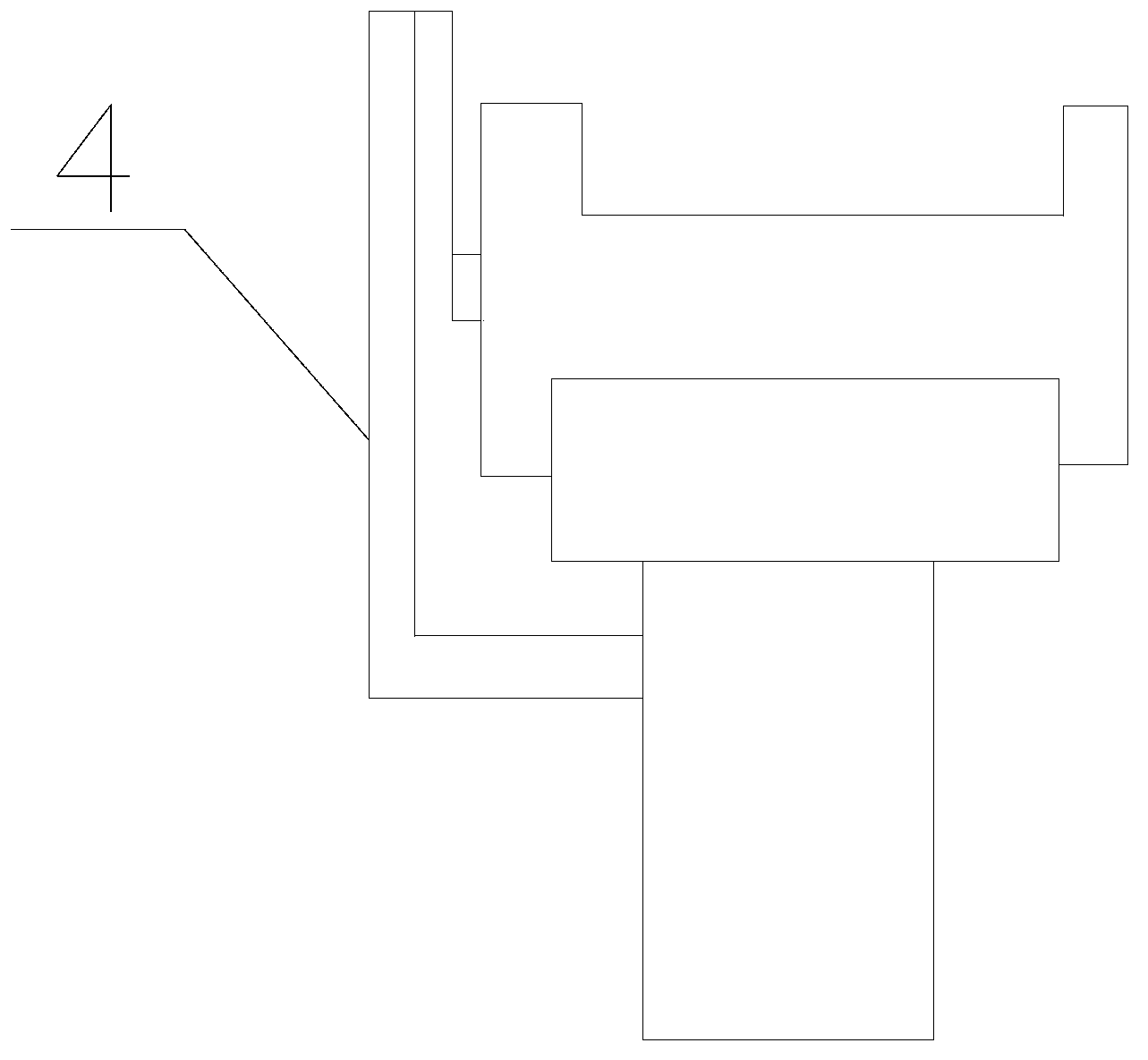

[0020] Such as figure 1 , 2 As shown, the present invention is a special hoisting device for shaft rollers, including two rails 1, a hoisting frame and a hoisting device; the hoisting frame is composed of two moving mechanisms 2 and a beam 3, and the bottom of the moving mechanism 2 is provided with The roller used in conjunction with the track 1 is provided with an anti-derailment structure 4 on the outside of the roller; the lifting device is composed of an electric hoist 5 and a lifting tool 6, and the bottom end of the wire rope on the electric hoist 5 is provided with a lifting tool 6, and the lifting device is provided with There are two parts, and the lifting device is controlled by an electric control switch.

[0021] The crossbeam 3 is provided with a reinforcing rod 7, the moving mechanism 2 and the crossbeam 3 are provided with a fixed rod 8, and the hoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com