High-efficiency and energy-saving double suction fan

A high-efficiency, energy-saving, suction fan technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of adjusting the blade opening not to zero, design difficulty, flow deviation, etc., to achieve axial size reduction, energy The effect of small loss and reduction of complete set cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical scheme of the present invention will be further described below in conjunction with the drawings and preferred embodiments of the present invention.

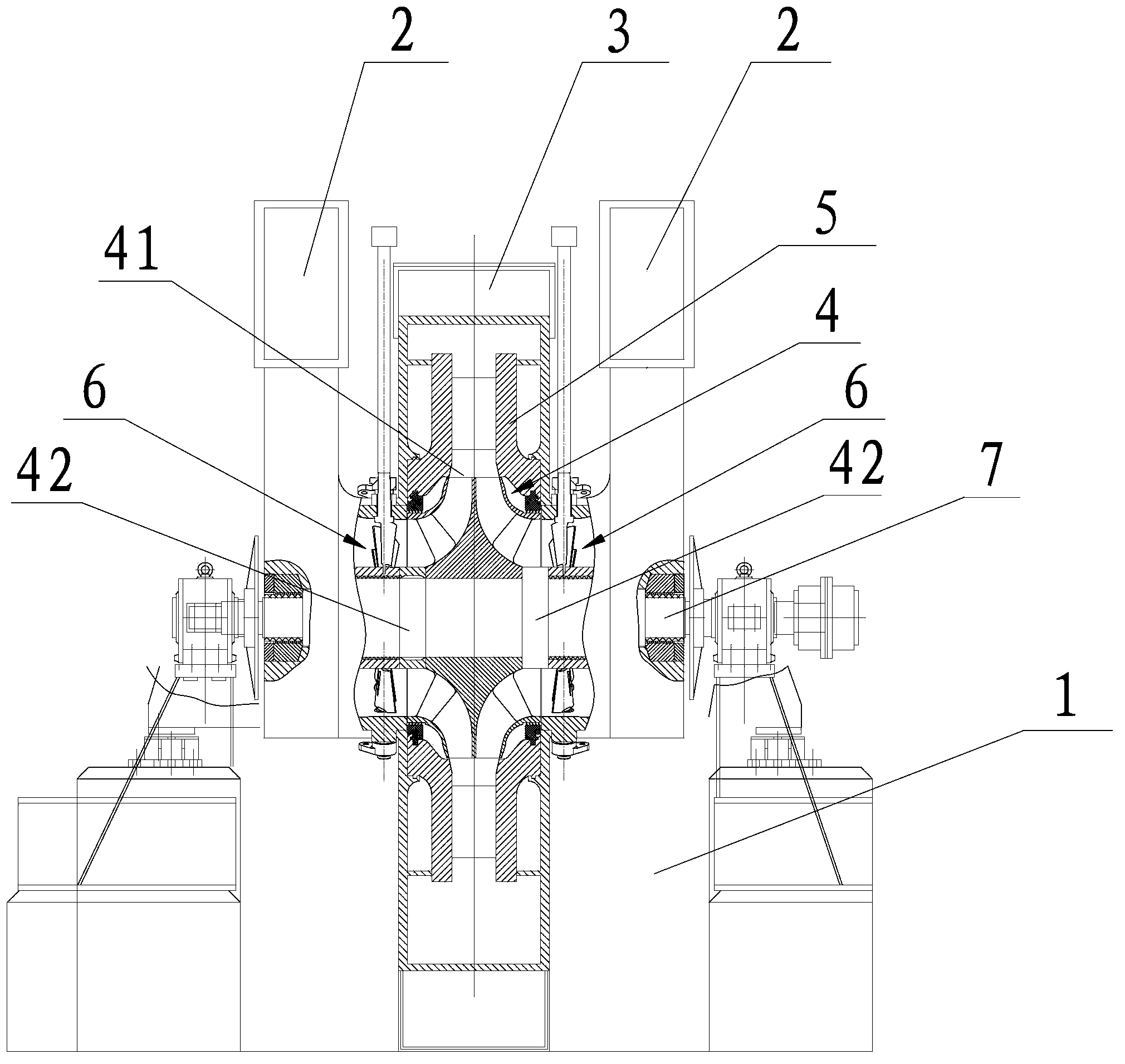

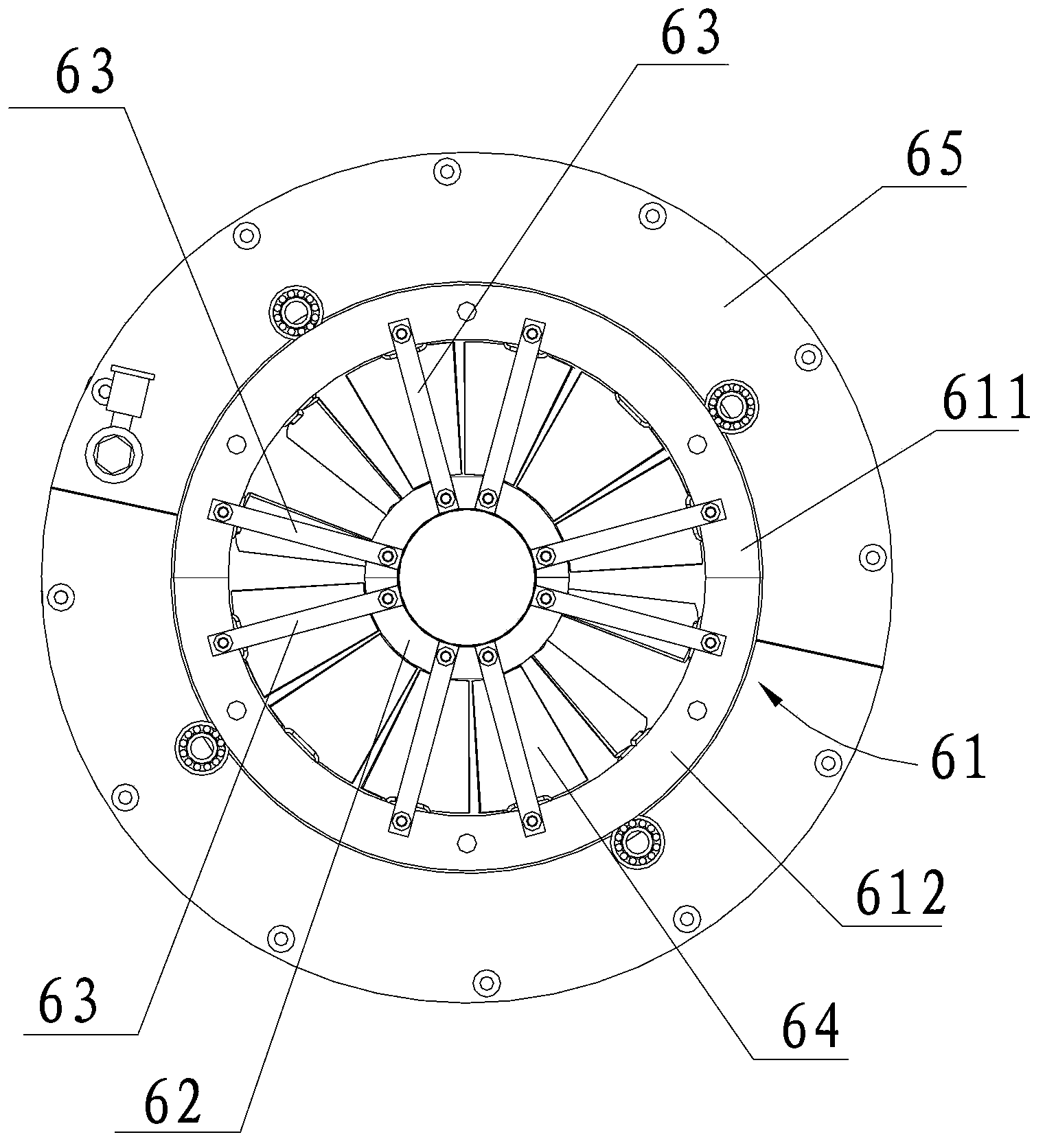

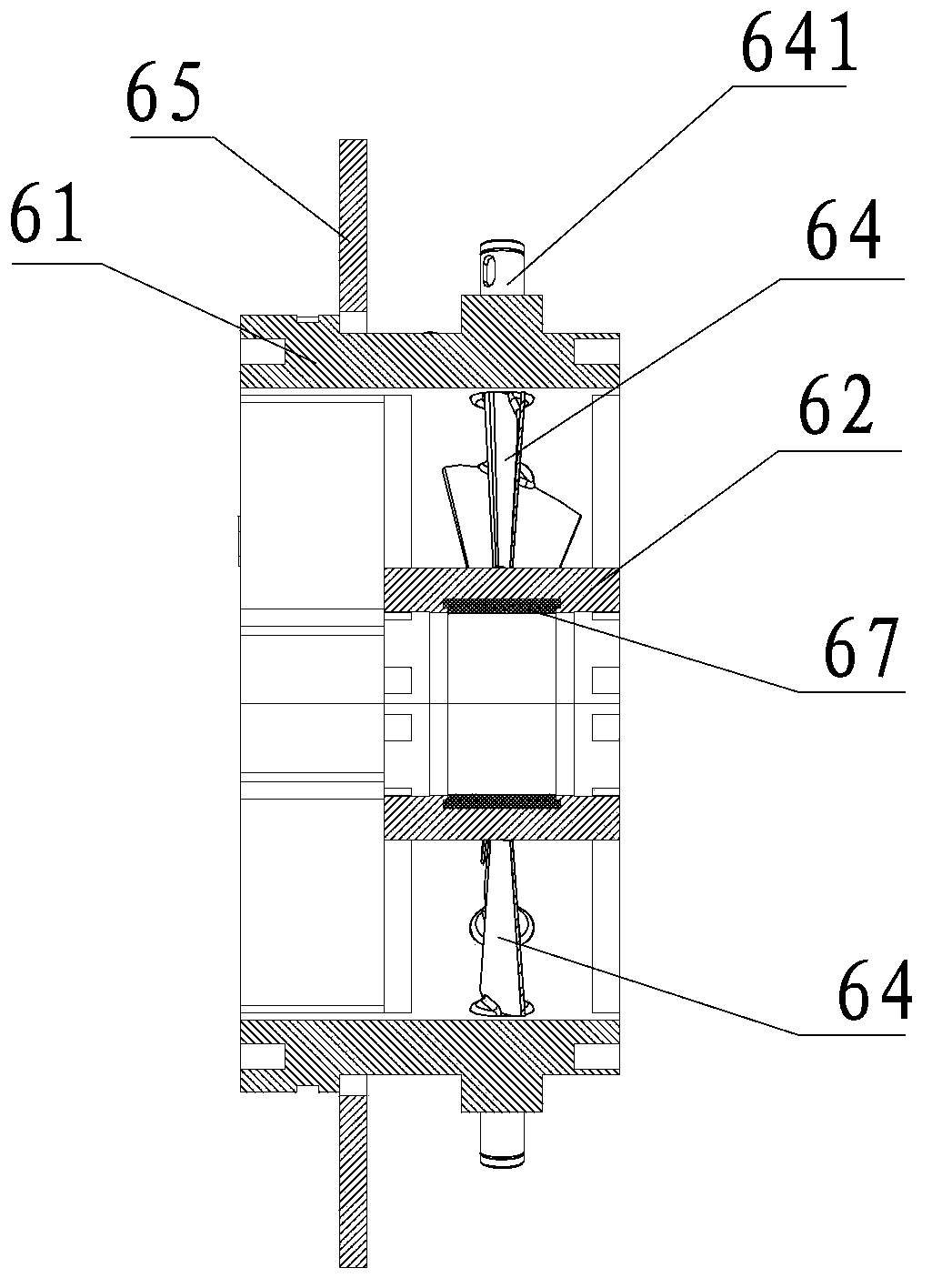

[0027] See figure 1 The shown high-efficiency and energy-saving double-suction fan includes a casing with an inner cavity 1, an air outlet 3 communicating with the inner cavity of the casing 1, and two air inlets 2, the two air inlets 2 are located respectively Both sides of the air outlet 3. The double-suction fan also includes a two-way intake impeller 4, a diffuser 5, and two intake pre-rotators 6. The two-way intake impeller 4 is rotatably arranged on the casing 1 through a rotating shaft 7 around its own axis. In the inner cavity, the two-way air inlet impeller 4 has an air outlet 41 and two air inlets 42 at both ends, and an air inlet pre-rotator 6 is provided between each air inlet 42 and the air inlet 2 on the corresponding side. , The intake pre-rotator 6 can be coaxially arranged with the two-way i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com