Load device for electric power fitting abrasion test machine

A wear test and power fitting technology, used in measuring devices, testing wear resistance, instruments, etc., can solve the problems of ineffective detection of wear test, difficult adjustment of load and weight, high labor intensity, and achieve good practical performance and work. The effect of low intensity and labor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

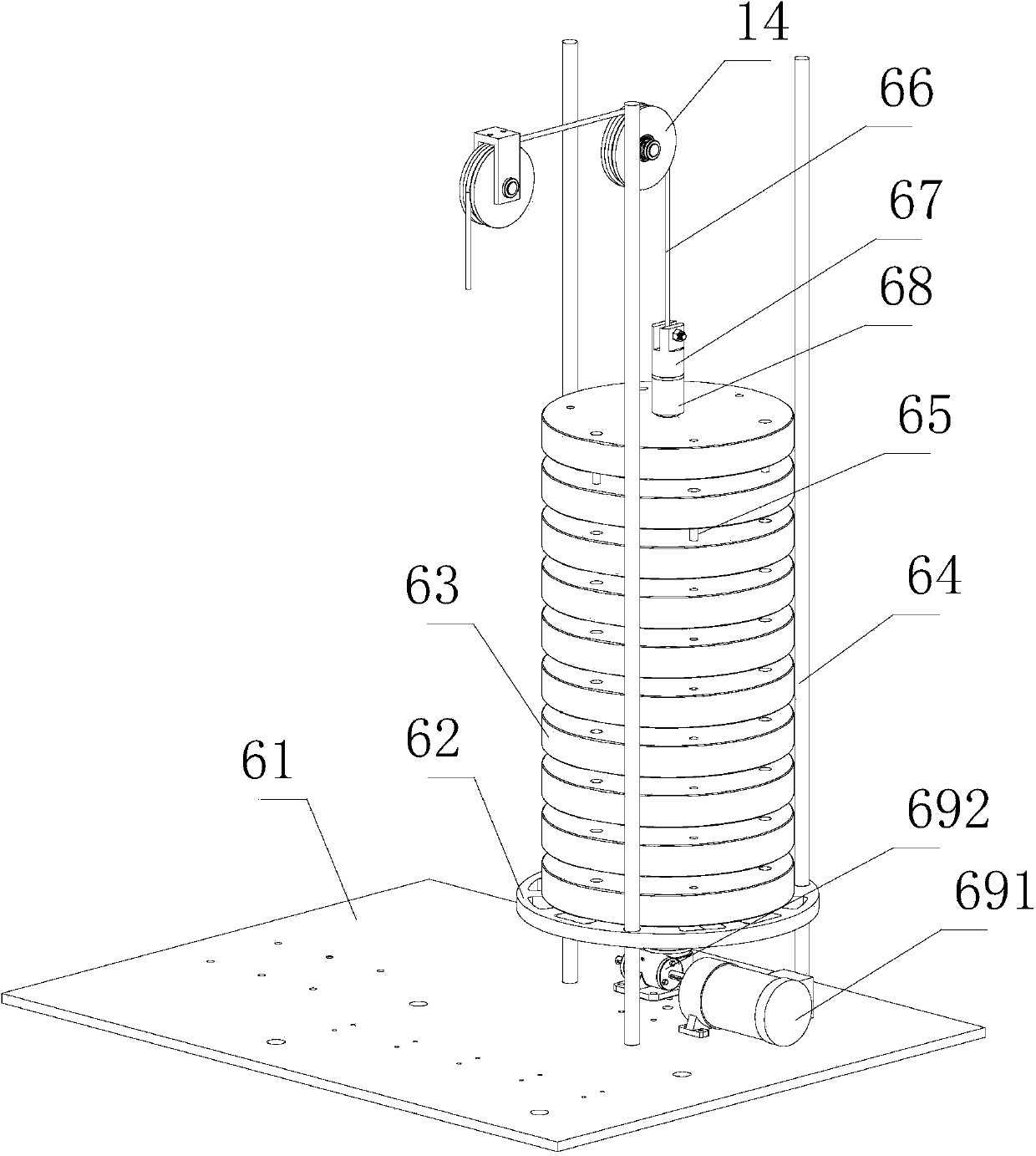

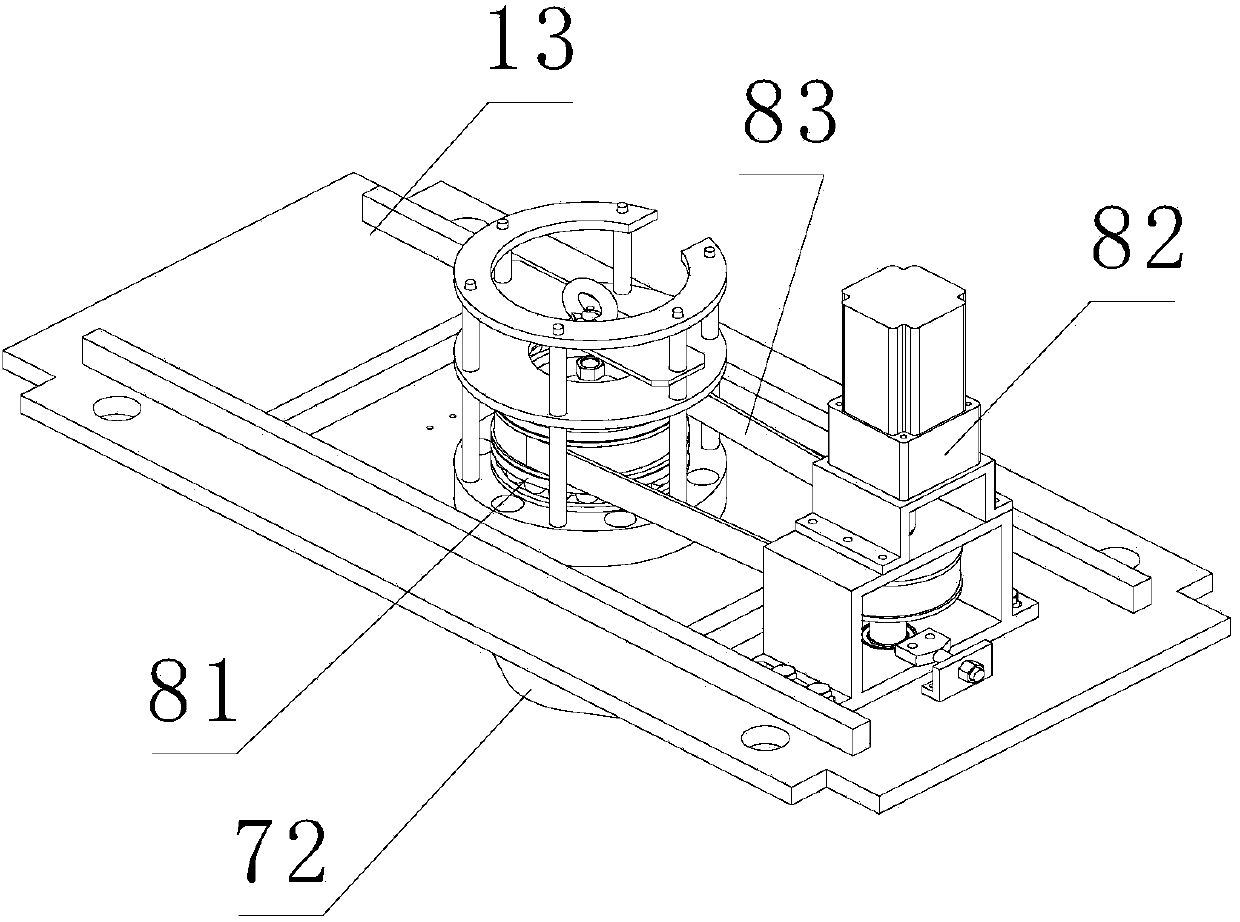

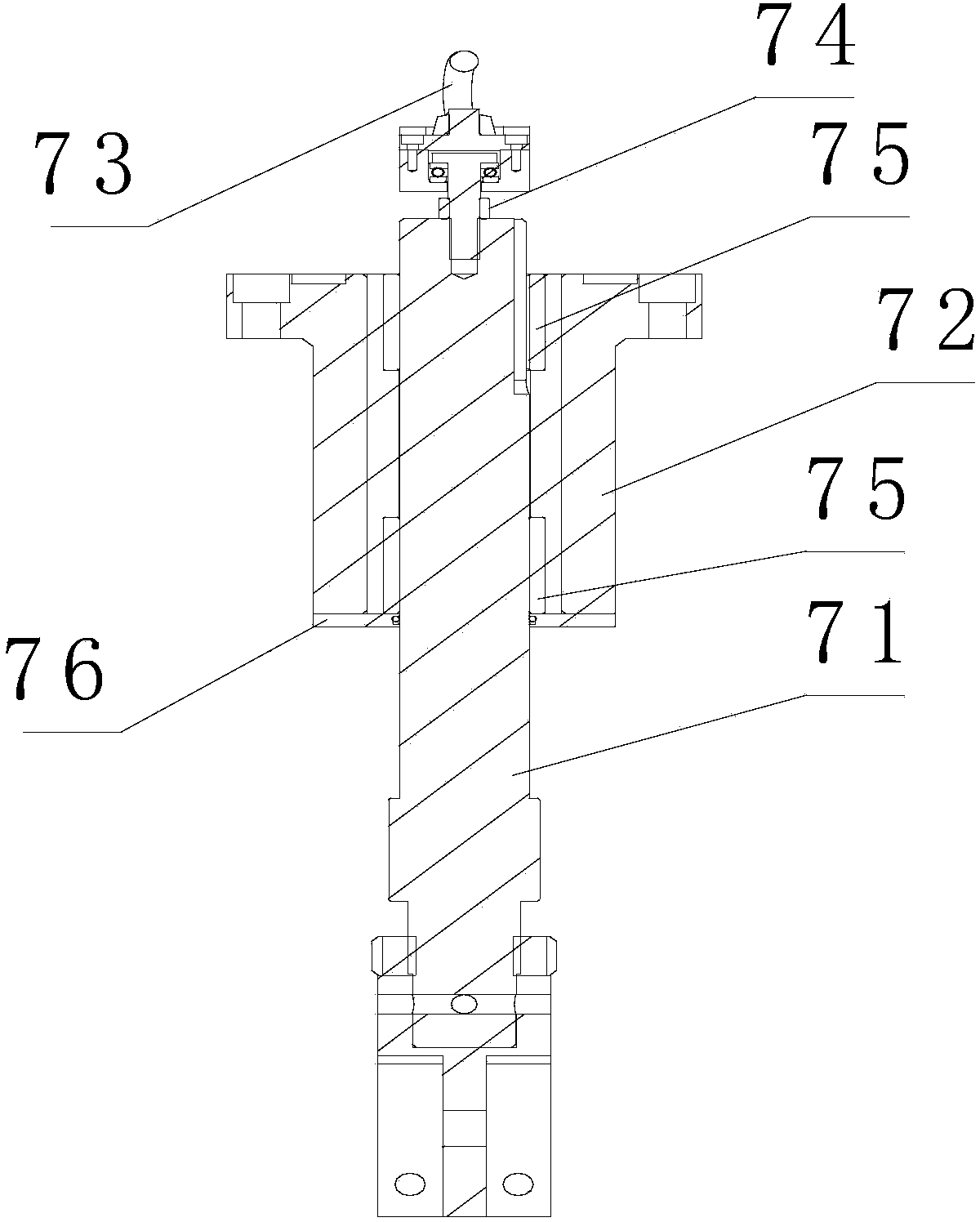

[0019] Such as figure 1 , figure 2 , image 3 As shown, the load device for the electric power fittings wear tester includes a frame, a bottom plate 61 fixed on the frame, a lifting block 62 movable on the bottom plate 61, and a plurality of weight plates 63 movable on the lifting block 62. The bottom plate 61 is provided with a control device for controlling the movement of the lifting block 62, the bottom plate 61 is provided with at least two movable guide columns 64 for controlling the lifting block 62, and at least two adjacent weight plates 63 are provided with at least one Two control rods 65, described frame is provided with the guiding device that links to each other with weight plate 63, and described weight plate 63 is ten pieces, and the weight of every described weight plate 63 is 100Kg, and described guiding device Including a guide shaft 71, a guide sleeve 72 arranged on the guide shaft 71, the guide sleeve 72 is fixed on the frame through the fixing plate 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com