Encapsulation structure of wire winding type electronic device and chip inductor

A technology of electronic devices and packaging structures, applied in the direction of transformer/inductor core, transformer/inductor coil/winding/connection, inductor with magnetic core, etc. Defective rate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

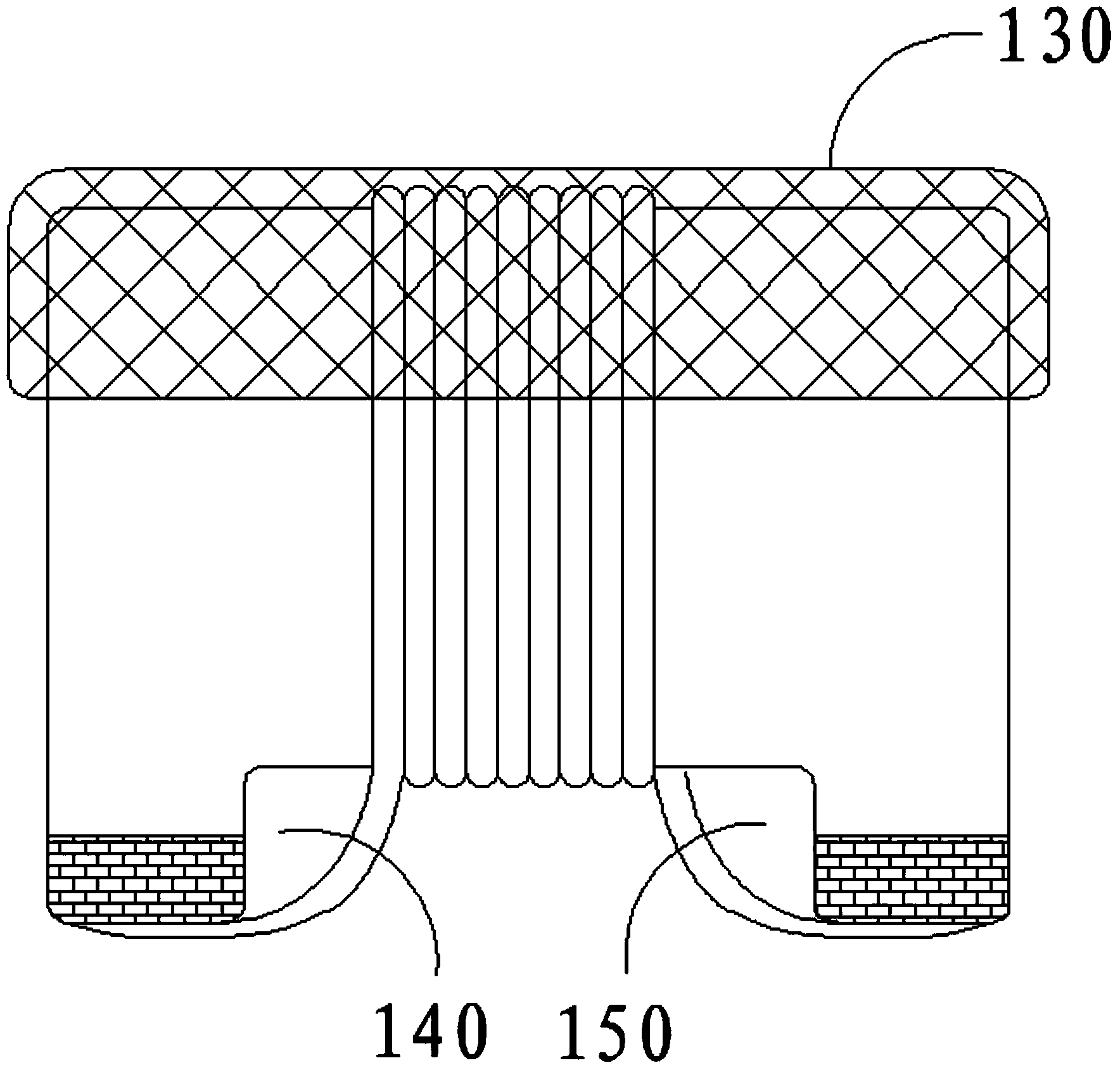

[0019] figure 1 It is a side view of the packaging structure of a traditional wirewound chip inductor. Since the packaging glue 130 only covers part of the coil, the exposed coil is not effectively protected, and there are gaps 140 and 150 between the coil lead wire and the inductor core. Coil lead wires are not protected by encapsulant.

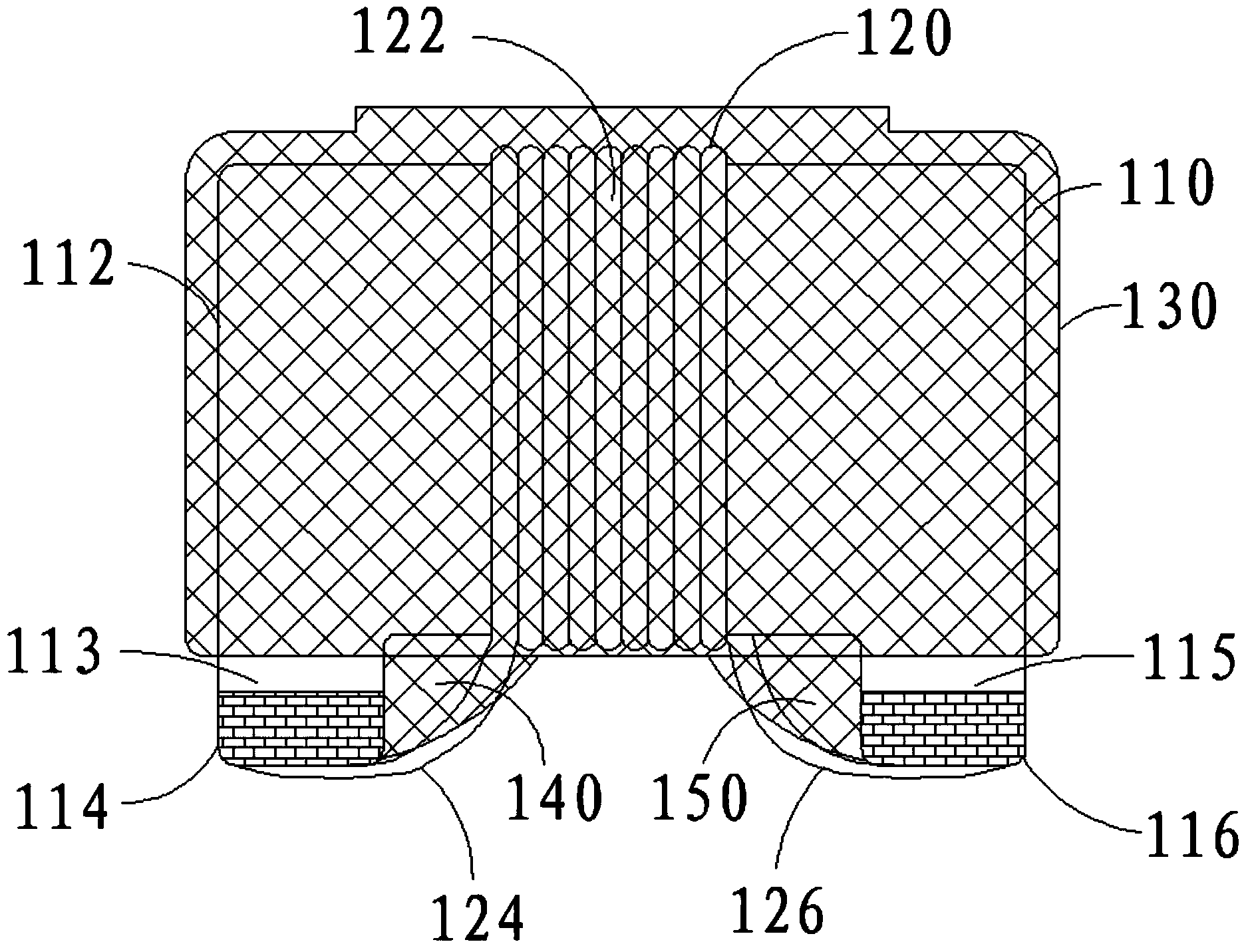

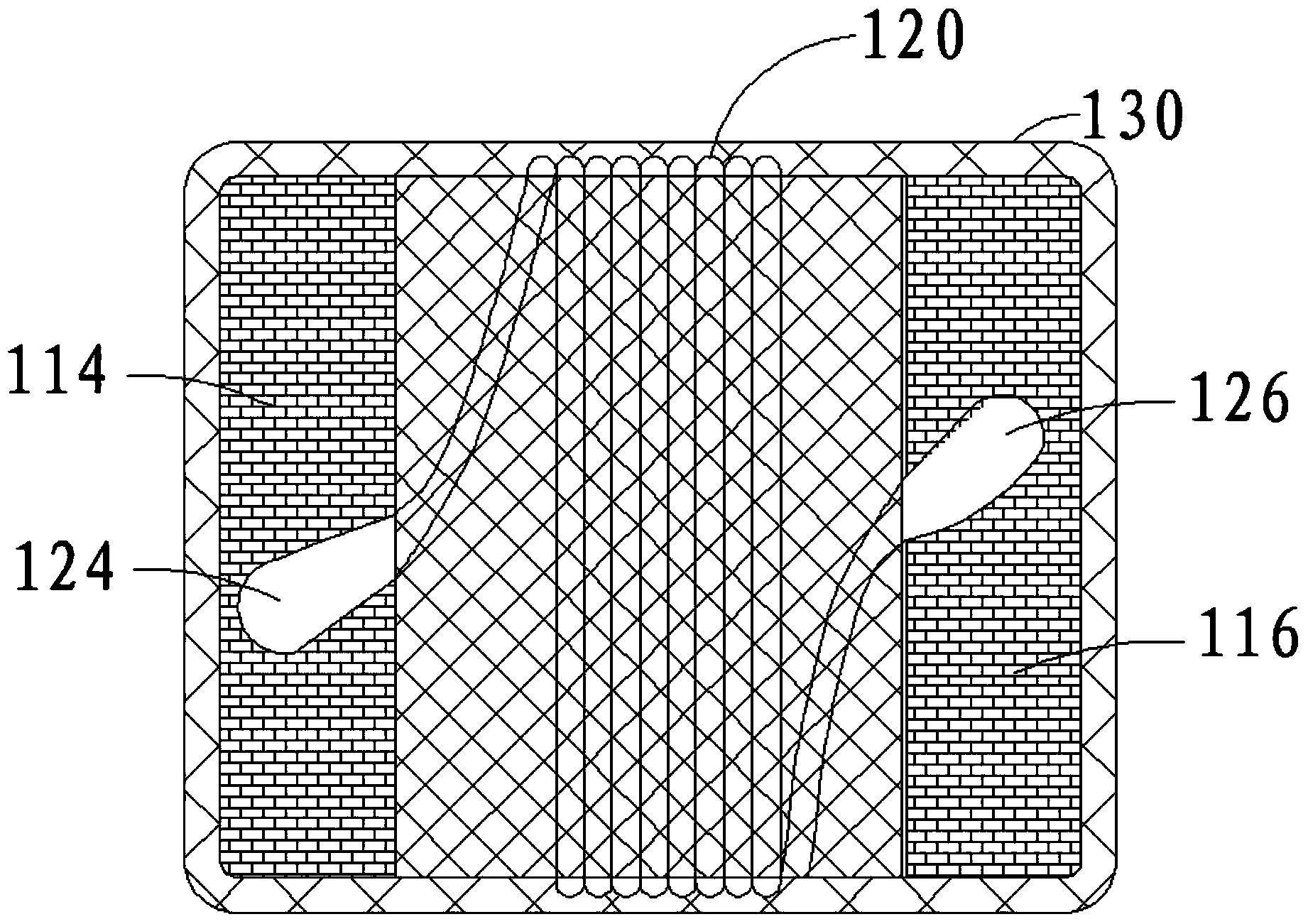

[0020] figure 2 It is a side view of the packaging structure of the wire-wound chip inductor according to an embodiment of the present invention, image 3 for figure 2 Bottom view of package structure of the shown wirewound chip inductor.

[0021] refer to figure 2 and image 3 , The packaging structure of the wirewound chip inductor in this embodiment includes an inductor core 110 , a coil 120 and a packaging glue 130 . The encapsulant 130 is made of UV curable resin (UV Curable Res...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap