Liquid crystal display element and method for manufacturing same

A technology of liquid crystal display elements and manufacturing methods, applied in liquid crystal materials, chemical instruments and methods, optics, etc., capable of solving problems such as image retention, difficulty in dripping marks, and insufficient effects, etc., achieving excellent high-speed response and occurrence of image retention The effect that there are few occurrences of drip marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

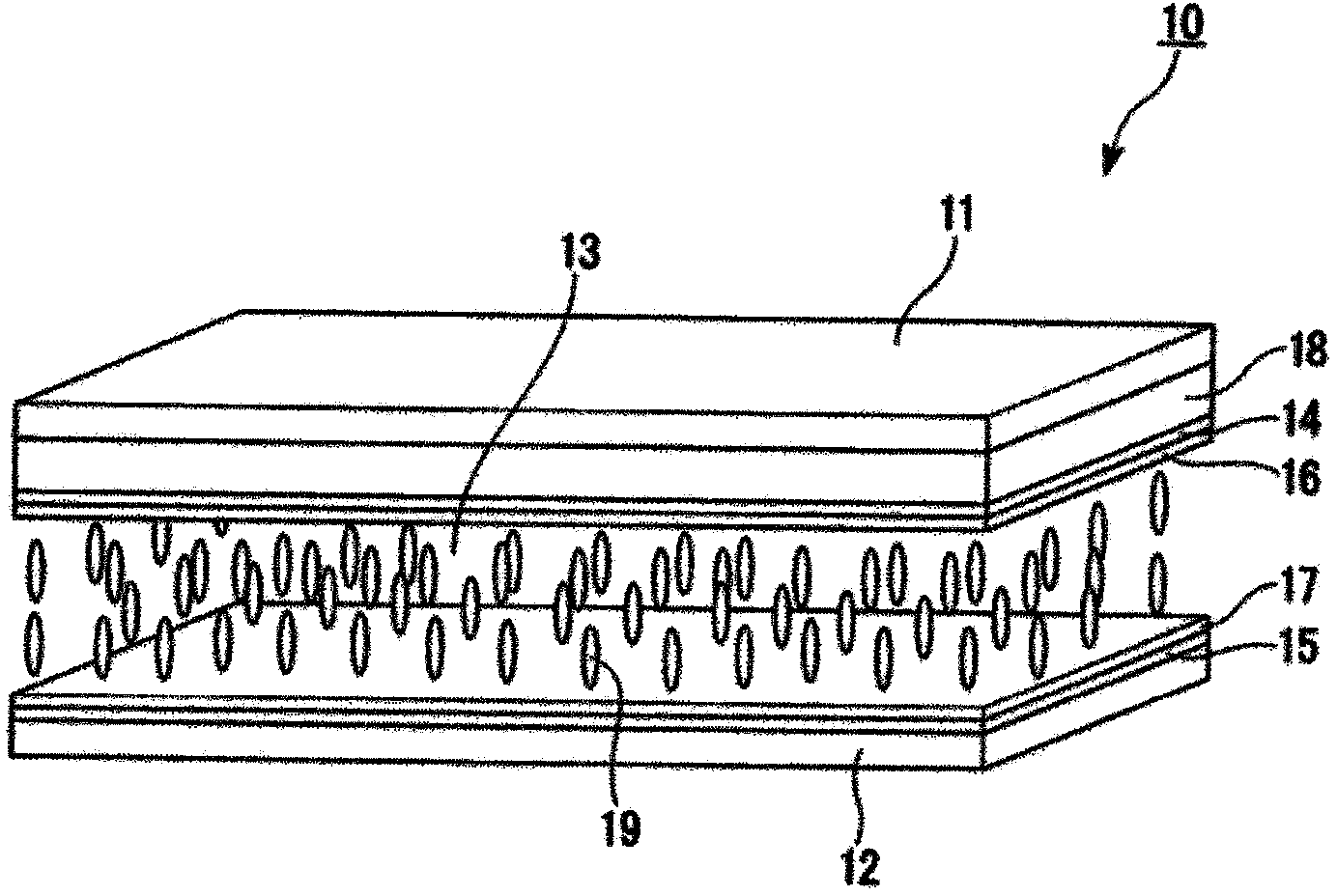

[0223] Fabricate a first substrate (common electrode substrate) and a second substrate (pixel electrode substrate), the first substrate has a transparent electrode layer and a color filter layer composed of a transparent common electrode, and the second substrate has The pixel electrode layer of the transparent pixel electrode driven by the source element.

[0224] A vertical alignment film material containing a polymerizable liquid crystal compound and a polymerization initiator was coated on each of the common electrode substrate and the pixel electrode substrate by spin coating to form a precursor layer of a vertical alignment film with a thickness of 200 nm. As a vertical alignment film forming material, UCL-011-K1 (manufactured by DIC Corporation) was used.

[0225] The substrates coated with the material for forming a vertical alignment film were heated in a constant temperature bath at 70° C. for 15 minutes to make the polymerizable liquid crystal compound in the materi...

Embodiment 1

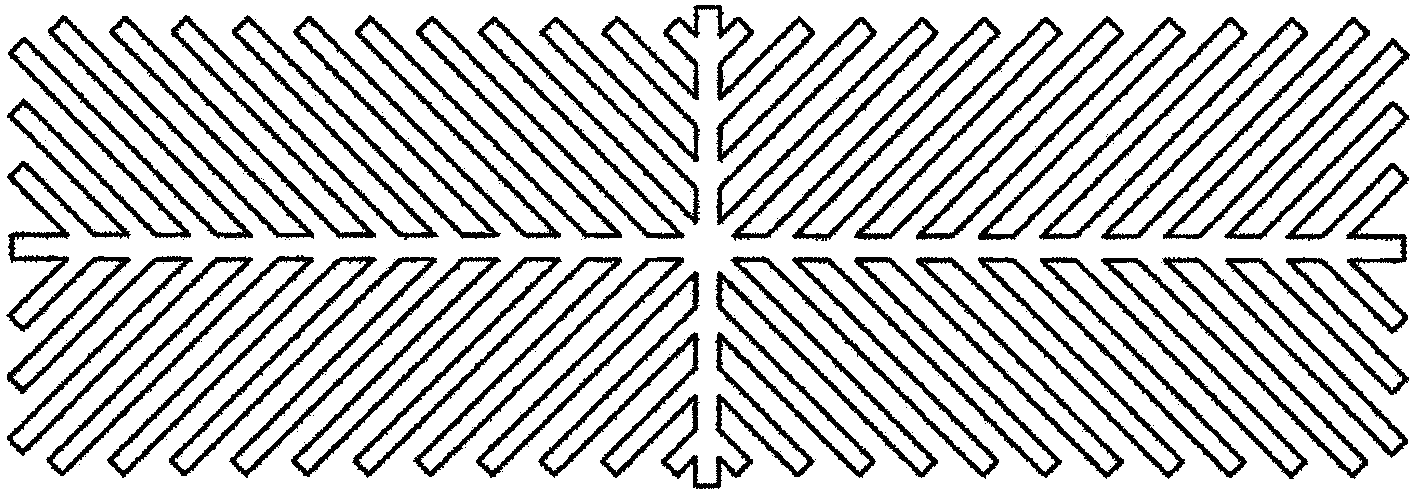

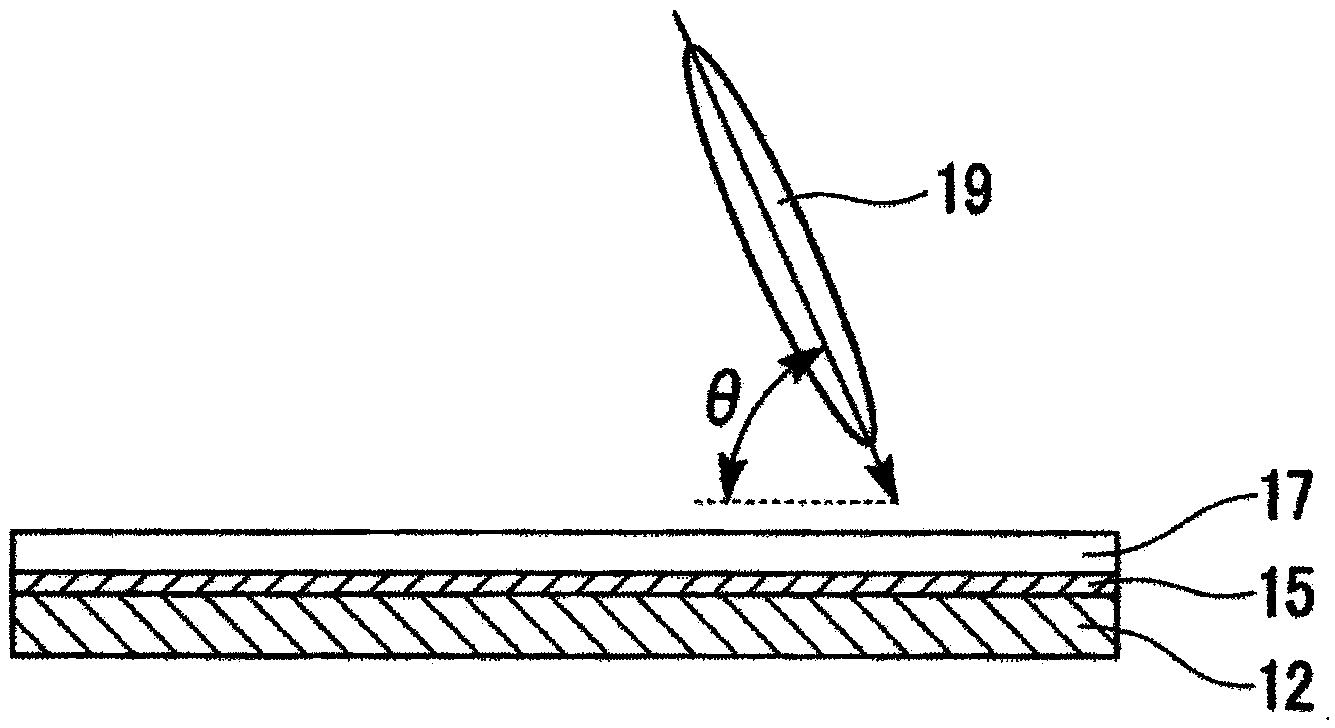

[0233] The liquid crystal display element of embodiment 1 according to figure 2 The slits of the pixel electrode as shown have pretilt angles in different directions in four sections, and after the polymerizable compound is cured, the pretilt angles can be maintained even when the AC electric field is cut off. The maintained pretilt angle was 87°.

[0234] It can be seen that the liquid crystal display element of Example 1 obtained in this way exhibits excellent response speed as shown in Table 1, drip marks are less likely to occur, and is also excellent in image retention.

[0235] [Table 1]

[0236] T NI / ℃

Embodiment 2

[0275] As a material for forming a vertical alignment film, a polyimide solution containing 3% of a polyimide precursor (trade name: JALS2131-R6, manufactured by JSR Corporation) containing a reactive group represented by the following formula (V-2) is used. A liquid crystal display element of Example 2 was obtained in the same manner as in Example 1, except that a 3% solution of a polymeric compound was obtained.

[0276]

[0277] About the liquid crystal display element of Example 2, it carried out similarly to Example 1, and measured image retention and drip marks. The results are shown in Table 8.

[0278] As a result, it can be seen that the liquid crystal display element of Example 2 is inferior to the liquid crystal display element of Example 1, but exhibits excellent response speed, drip marks are less likely to occur, and is also excellent in image retention.

[0279] [Table 8]

[0280] Dripping Trace Evaluation

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com