Moisture drying device of combined drying tunnel

A drying device and combined technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of lower production efficiency, cumbersome operation, and adverse effects on product quality, and achieve convenient maintenance, beneficial effect on production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

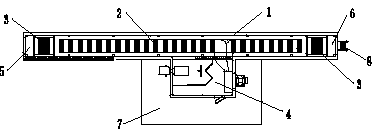

[0012] Combine below figure 1 Specific examples:

[0013] A moisture drying device of a combined drying tunnel, characterized in that, the moisture drying device of the combined drying tunnel includes a housing 1, and a plurality of drying drying tunnel chambers are arranged inside the housing 1 Body 2, the housing 1 is located at the two ends of the drying tunnel chamber body 2 is provided with a drying tunnel air curtain room 3, the side of the housing 1 is provided with a drying and drying tunnel The drying tunnel heating chamber 4 where the tunnel body 2 is heated is provided with an inlet 5 and an outlet 6 on the casing 1, and the inlet 5 and the outlet 6 are communicated with the drying tunnel air curtain chamber 3.

[0014] Preferably, an inspection platform 7 is provided on the casing 1.

[0015] Preferably, a climbing ladder 8 is provided at the exit 6.

[0016] In the moisture drying device of the combined drying tunnel provided by the present invention, when in use, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com