High-precision powder quantitative feeding machine

A quantitative feeder, high-precision technology, used in transportation and packaging, loading/unloading, etc., to solve problems such as unstable weighing, poor measurement accuracy, and measurement screw errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

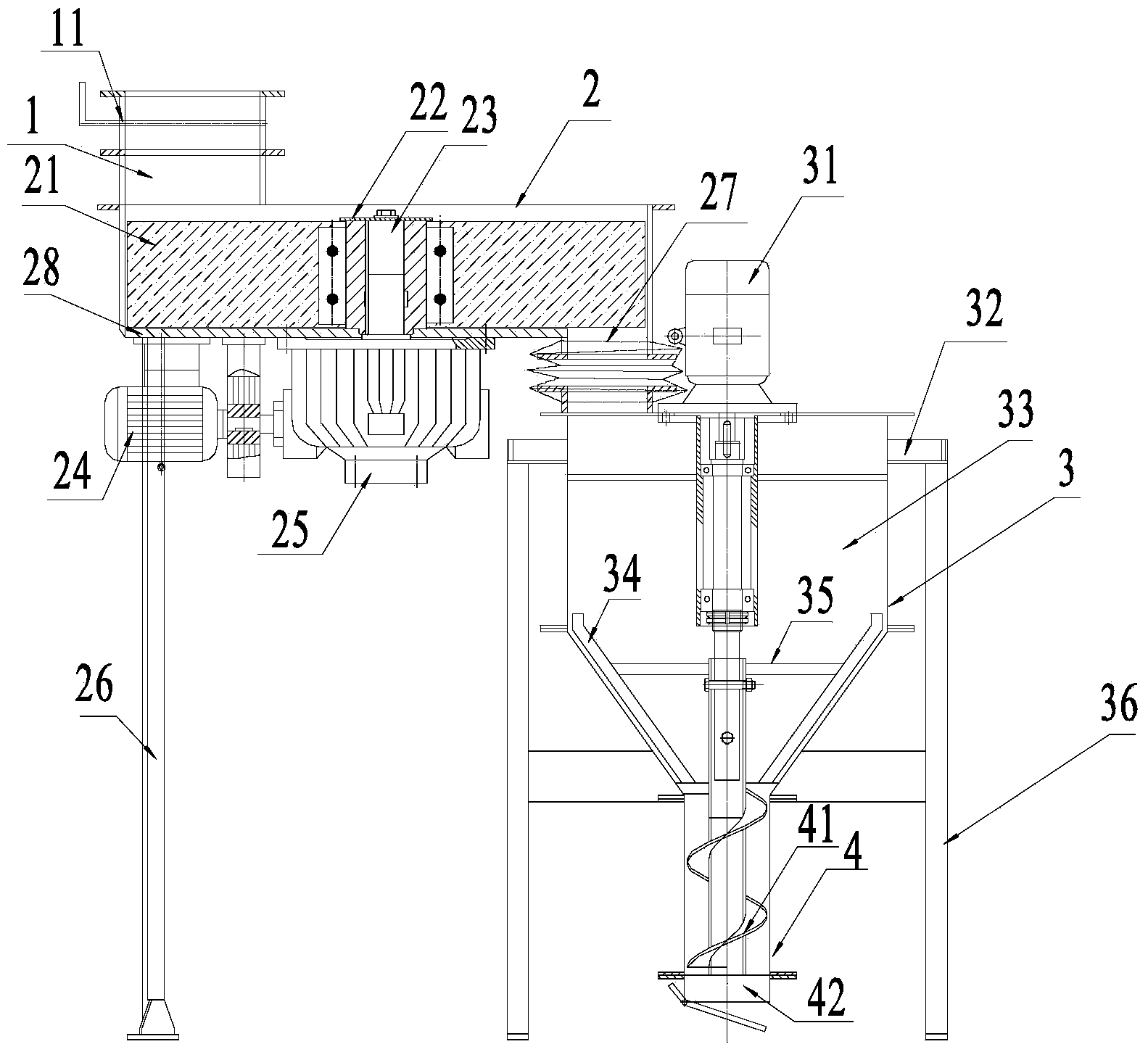

[0027] Such as figure 1 As shown, the high-precision powder quantitative feeder of the present invention includes a feeding pipe 1, a disc feeder 2, a weighing mechanism 3, and a discharging mechanism 4.

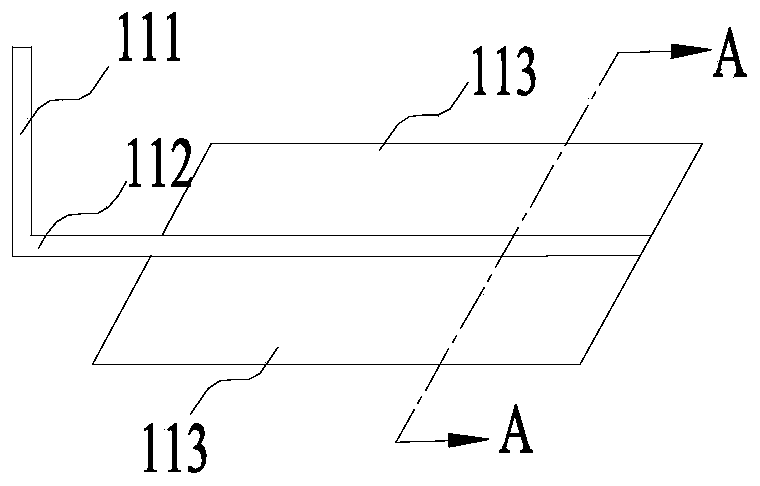

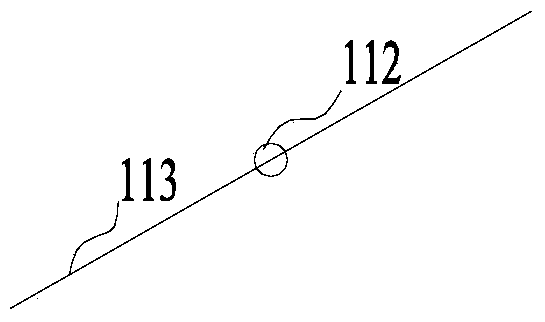

[0028] A flap valve 11 is set on the feeding pipe 1, such as figure 2 , image 3 , Figure 4 As shown, the flap valve 11 includes a flap shaft 112, a flap 113 is arranged on the flap shaft 112, the flap 113 is divided into a first flap and a second flap, and the first flap and the second flap are symmetrically arranged on Both sides of the turning shaft 112 are fixedly connected with the turning shaft 112 . The angle between the first flap and the second flap is 180°, and the size and shape of the first flap and the second flap should be set to match the feeding pipe, that is, when the first flap and the second flap When the boards are all in a horizontal state, the feeding pipe is just closed. One end of the turnover plate rotating shaft 112 exposes the pipe wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com