Dustproof plastic capable of being used for manufacturing appearance parts and preparation method thereof

A technology for appearance parts and dust prevention, which is applied in the field of resin formulation and its preparation, can solve problems such as easy to absorb dust, accumulate a layer of dust, affect the appearance of products, etc., and achieve the effect of easy to deposit dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A dust-proof plastic capable of making appearance parts, the method comprising the following steps:

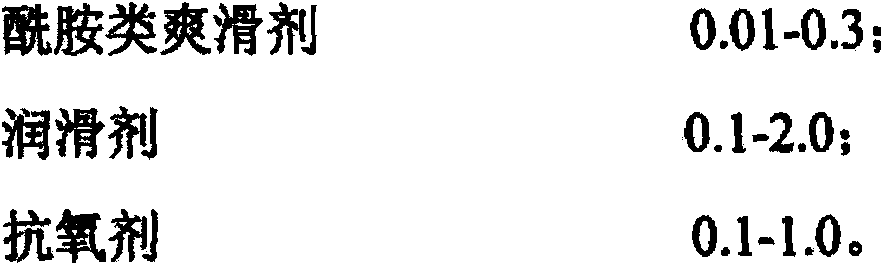

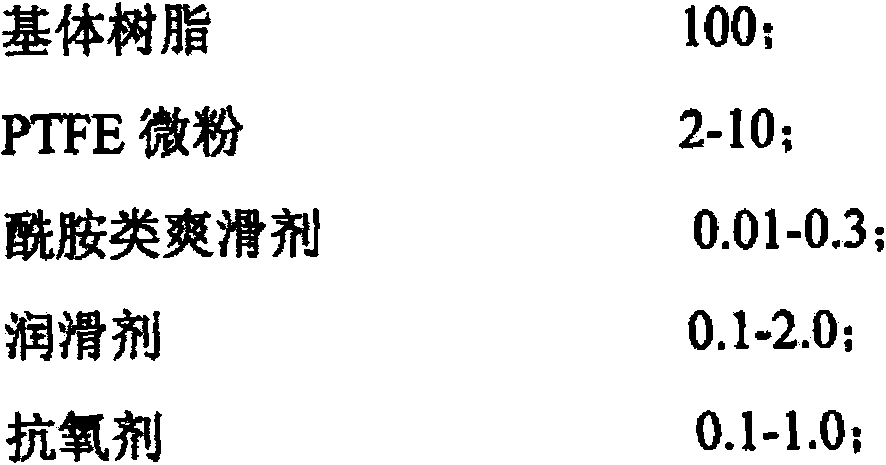

[0025] (1) Prepare materials according to the following components and parts by weight:

[0026]

[0027] (2) Put the above-mentioned (1) raw materials in a high-speed mixer according to the formula and stir them, and then send them into the twin-screw extruder through the metering device after mixing evenly. Under the conveying, shearing and mixing of materials, the materials are melted and compounded, and then extruded, drawn, cooled and pelletized to obtain a dust-proof plastic that can be used to make appearance parts.

[0028] Among them, the matrix resin is high-gloss ABS resin;

[0029] The molecular weight of PTFE micropowder is 1.0×10 4 , particle size 12μm;

[0030] The amide slip agent is erucamide E Powder produced by AkzoNobel;

[0031] The lubricant is EBS;

[0032] Antioxidant is Irganox B900.

Embodiment 2

[0034] A dust-proof plastic capable of making appearance parts, the method comprising the following steps:

[0035] (1) Prepare materials according to the following components and parts by weight:

[0036]

[0037] (2) Put the above-mentioned (1) raw materials in a high-speed mixer according to the formula and stir them, and then send them into the twin-screw extruder through the metering device after mixing evenly. Under the conveying, shearing and mixing of materials, the materials are melted and compounded, and then extruded, drawn, cooled and pelletized to obtain a dust-proof plastic that can be used to make appearance parts.

[0038] Among them, the matrix resin is high-gloss ABS resin;

[0039] The molecular weight of PTFE micropowder is 1.0×10 4 , particle size 12μm;

[0040] The amide slip agent is erucamide E Powder produced by AkzoNobel;

[0041] The lubricant is EBS;

[0042] Antioxidant is Irganox B900.

Embodiment 3

[0044] A dust-proof plastic capable of making appearance parts, the method comprising the following steps:

[0045] (1) Prepare materials according to the following components and parts by weight:

[0046]

[0047] (2) Put the above-mentioned (1) raw materials in a high-speed mixer according to the formula and stir them, and then send them into the twin-screw extruder through the metering device after mixing evenly. Under the conveying, shearing and mixing of materials, the materials are melted and compounded, and then extruded, drawn, cooled and pelletized to obtain a dust-proof plastic that can be used to make appearance parts.

[0048] Among them, the matrix resin is high-gloss ABS resin;

[0049] The molecular weight of PTFE micropowder is 1.0×10 4 , particle size 12μm;

[0050] The amide slip agent is erucamide E Powder produced by AkzoNobel;

[0051] The lubricant is EBS;

[0052] Antioxidant is Irganox B900.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap