Fireproof door capable of blocking off crack after meeting heat

A technology for fire doors and heat exposure, which is applied in the field of fire doors, and can solve problems such as failure to meet fire-resistant requirements, easy ablation and burn-through of fire-resistant material strips, and short fire-resistant time of fire doors, so as to block smoke and poisonous gas, prevent The effect of spreading fire and increasing the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

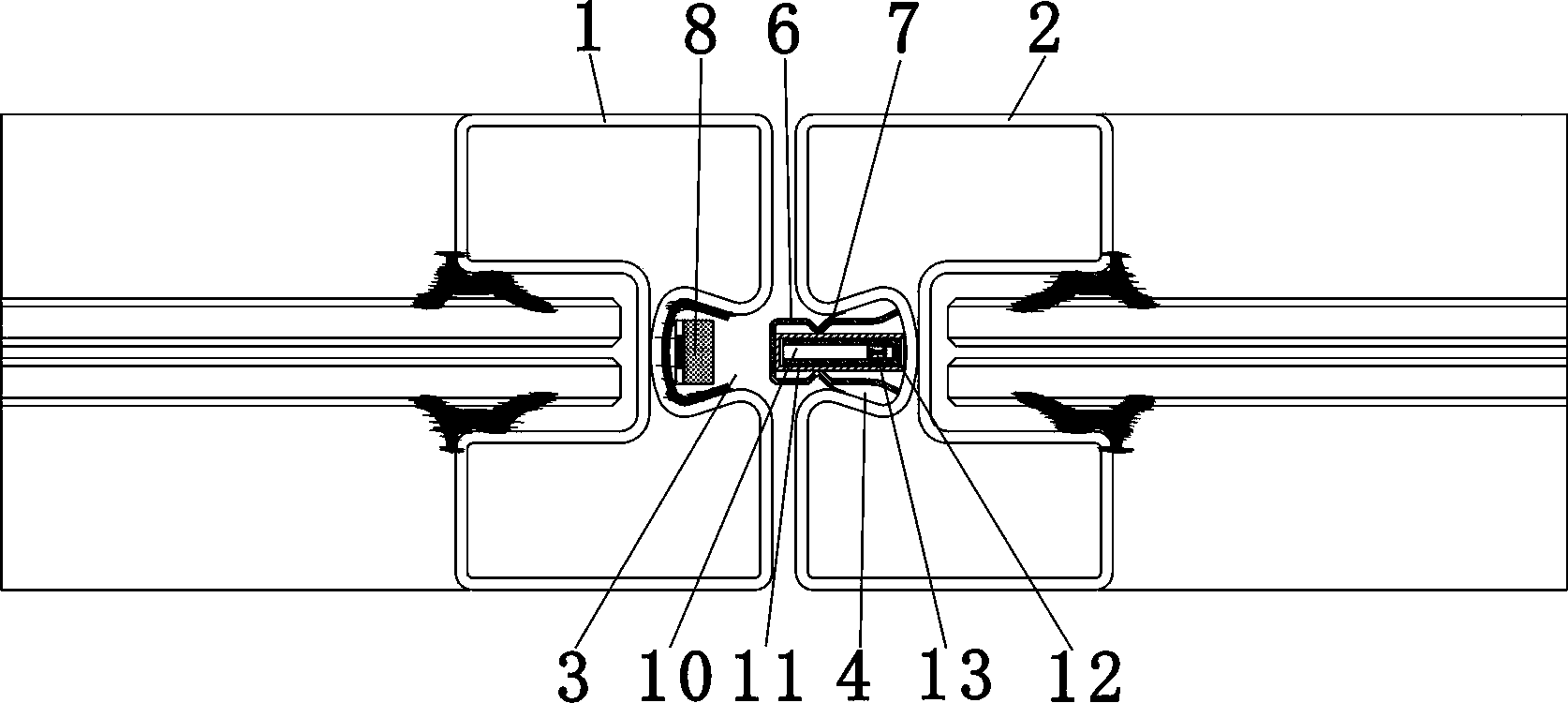

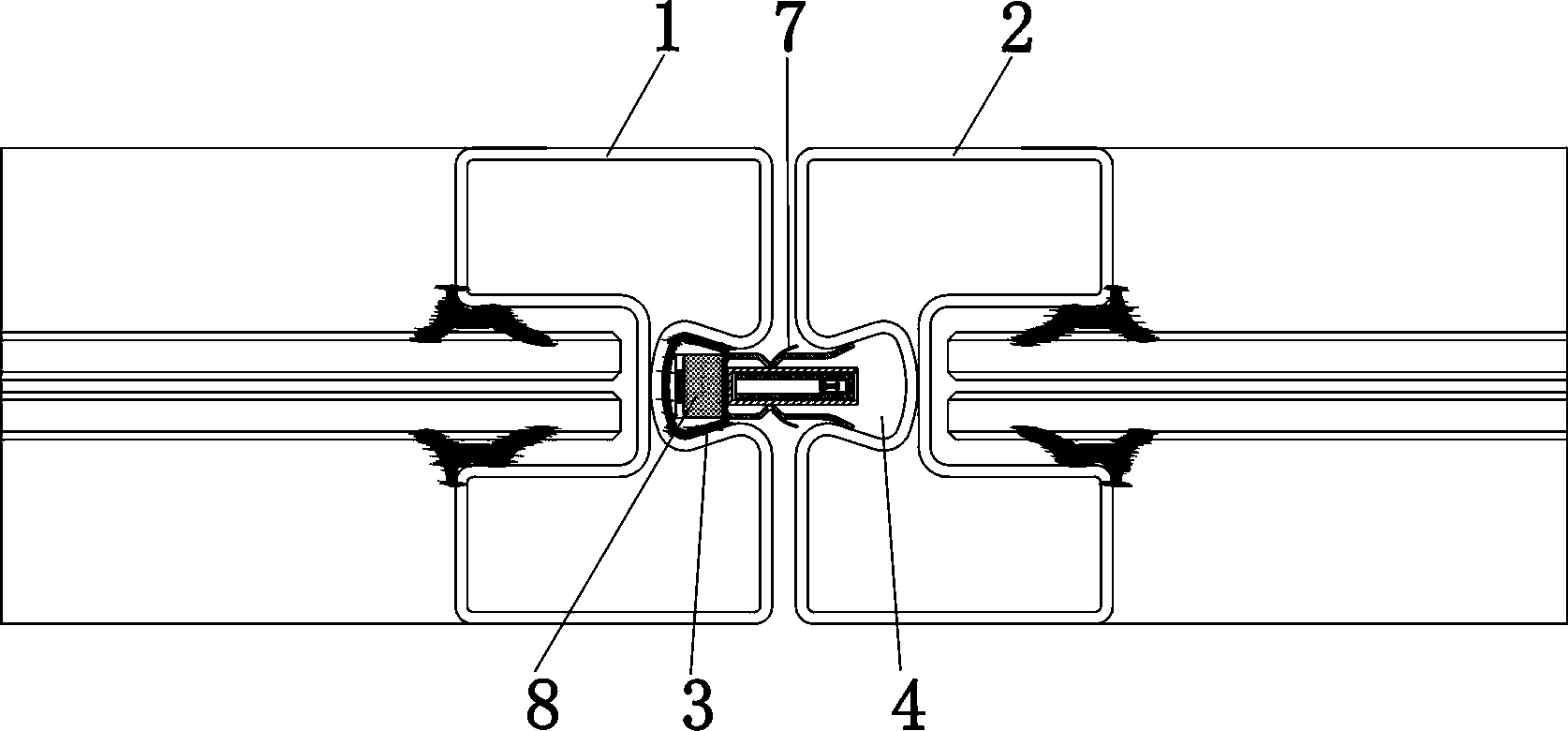

[0021] figure 1 , figure 2 The shown fire door 1 and door frame 2 of the fire door that seals the door gap when exposed to heat have dovetail grooves 3 and 4 respectively.

[0022] There is a U-shaped sealing steel groove 5 in the dovetail groove 4 of the door frame 2 , and the notch of the sealing steel groove 5 faces the groove bottom of the dovetail groove 4 . The outer side of the sealing steel channel 5 is connected with an outwardly bent elastic member 6, and the elastic member 6 is stuck inside the notch of the dovetail groove 4, so that the sealing steel channel 5 is fixed in the dovetail groove 4, preventing the sealing steel channel 5 from outward Falling off, and avoid the impact noise of the sealing steel groove 5 and the dovetail groove 4 when the door leaf is opened and closed daily. There is an outwardly bent curved part 7 at the notch of the sealed steel channel 5. When the sealed steel channel 5 is heated and pops up, the curved part 7 is stuck inside the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com