Hydrostatic positive-displacement machine

一种静液压、液压介质的技术,应用在静液压排挤机领域,能够解决耗费、高结构等问题,达到小结构耗费的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

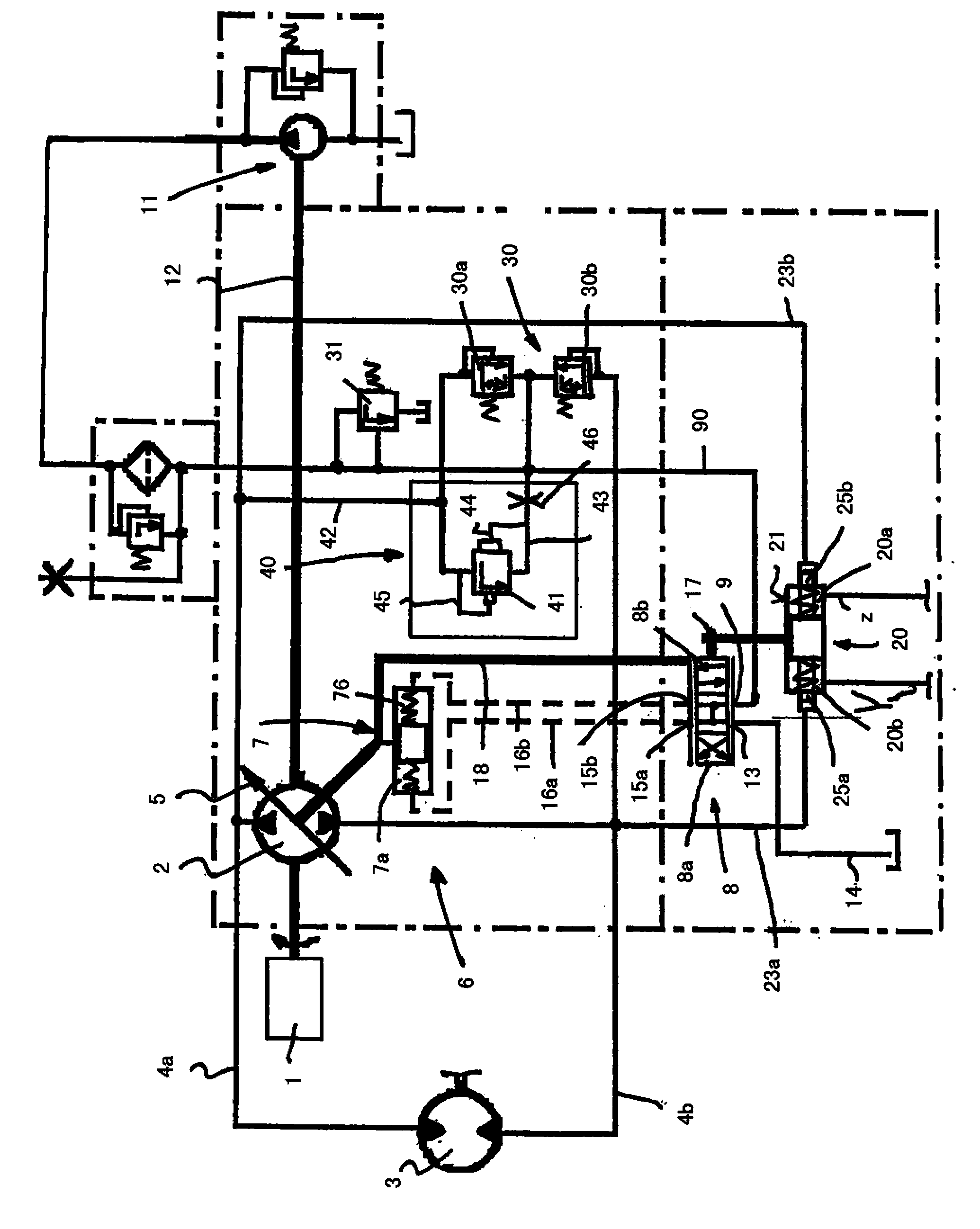

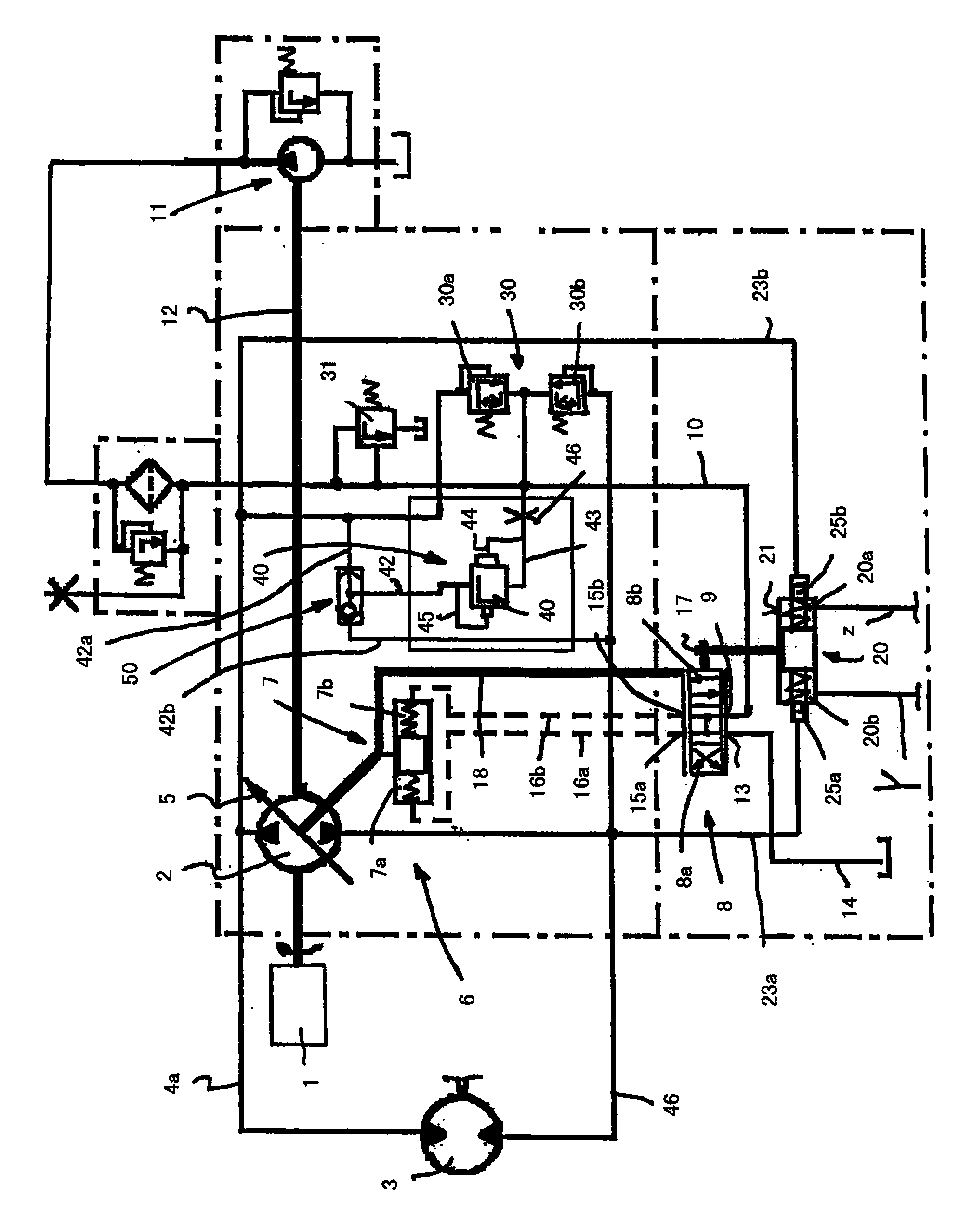

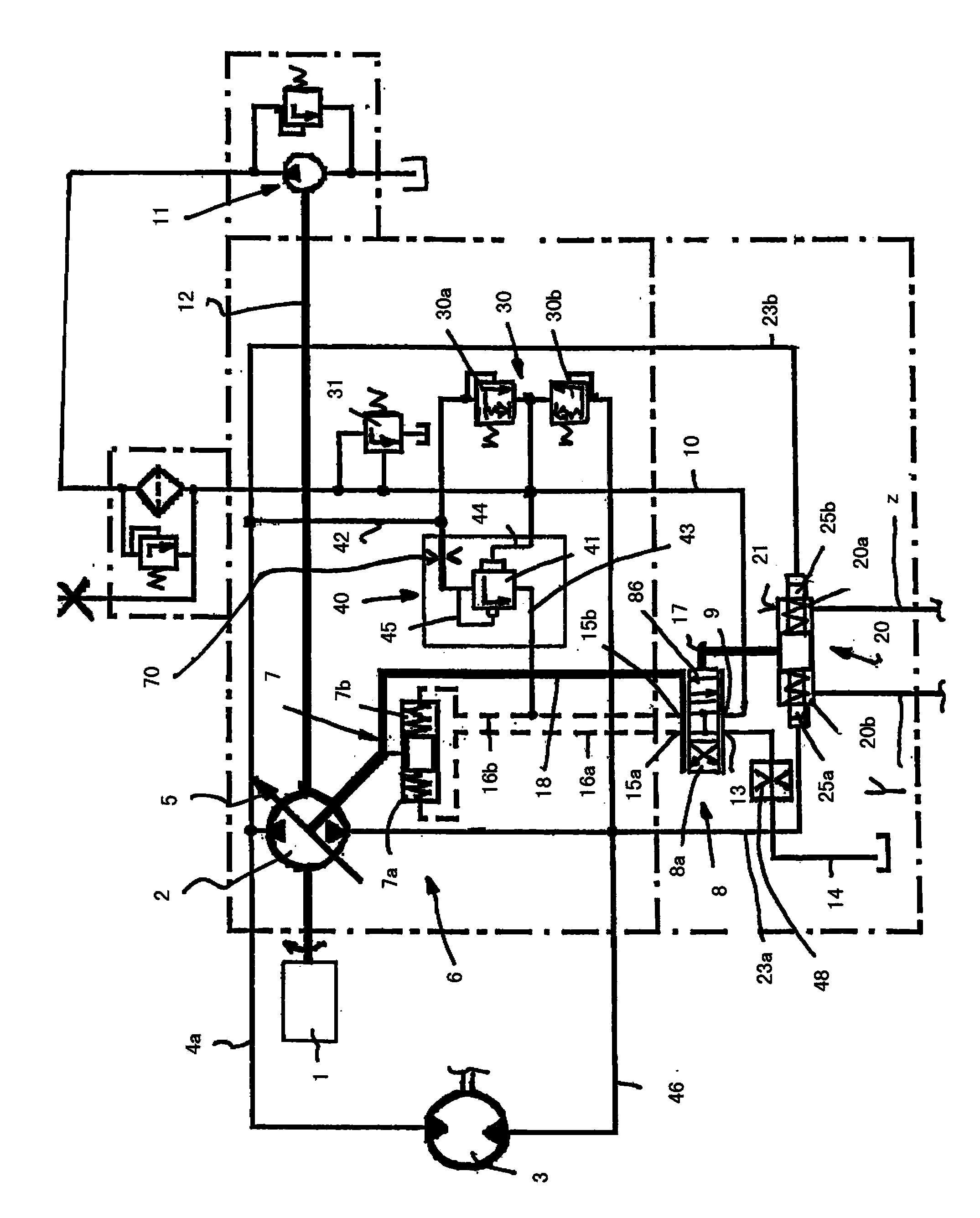

[0028] exist figure 1 shows, for example, a circuit diagram of a hydrostatic drive system in a closed circuit circuit of a mobile work machine, such as a wheel loader.

[0029] A hydrostatic displacement machine (or displacement machine) 2 designed as a pump is driven by a drive engine 1 , for example an internal combustion engine, which is connected in a closed circuit to at least one hydraulic load 3 , in particular a hydraulic motor. The load 3 is here connected in a manner not further shown to a drive wheel or a drive shaft of a drive machine. The closed circuit forms a working cycle into which the displacement machine 2 delivers hydraulic medium and which consists of a first hydraulic medium line 4 a and a second hydraulic medium line 4 b.

[0030] The displacement machine 2 is configured as an adjustable pump with a variable displacement volume and thus a variable delivery volume and has a displacement volume adjustment mechanism 5 for adjusting the displacement volume,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com