Oscillating hydraulic steering engine testing table

A test bench and steering gear technology, which is used in fluid pressure actuation system testing, mechanical equipment, fluid pressure actuation devices, etc., can solve the problems of high product testing costs, low testing efficiency, and large occupancy of the steering gear test site. Achieving the effect of beautiful appearance, cost reduction and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

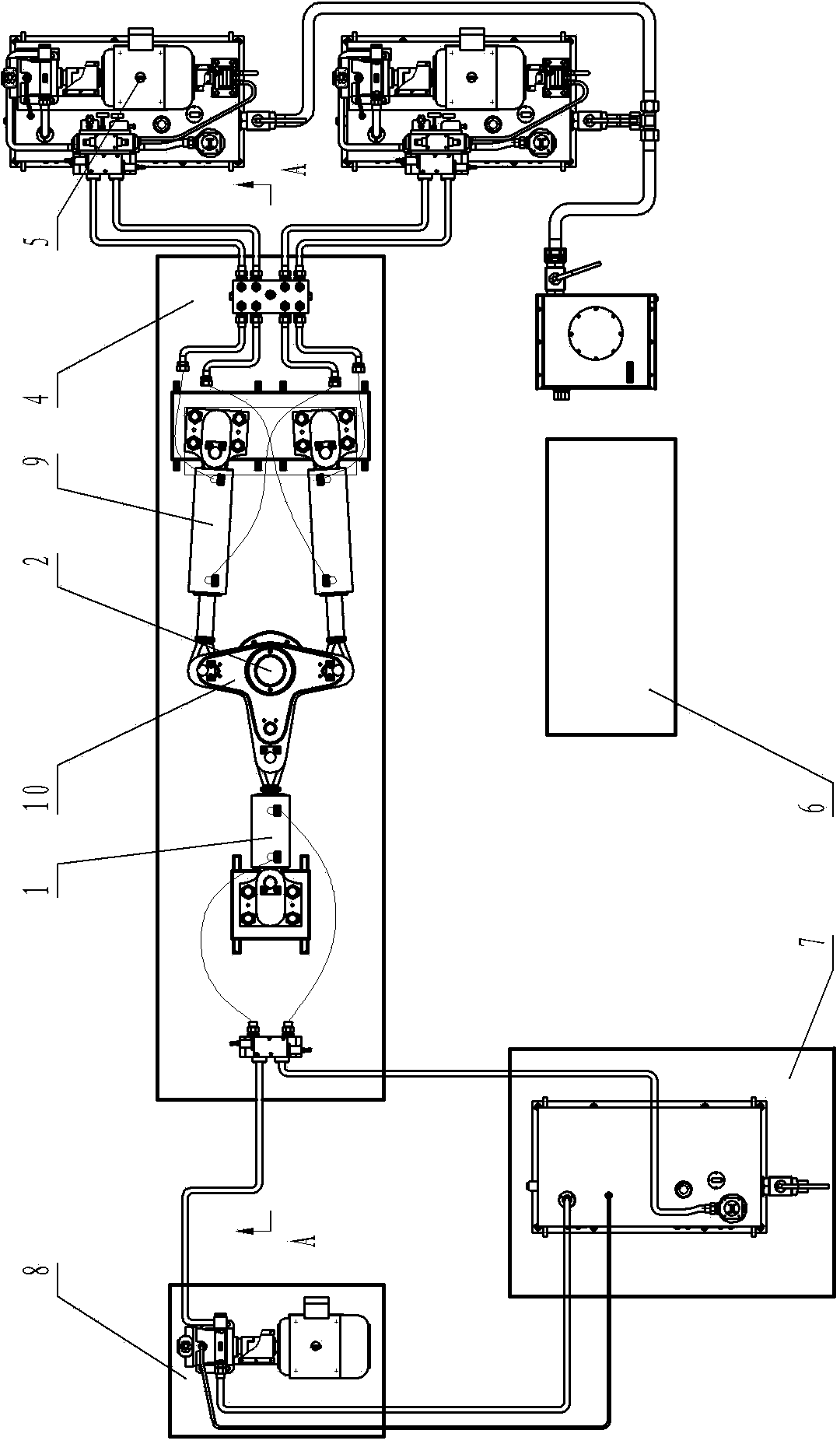

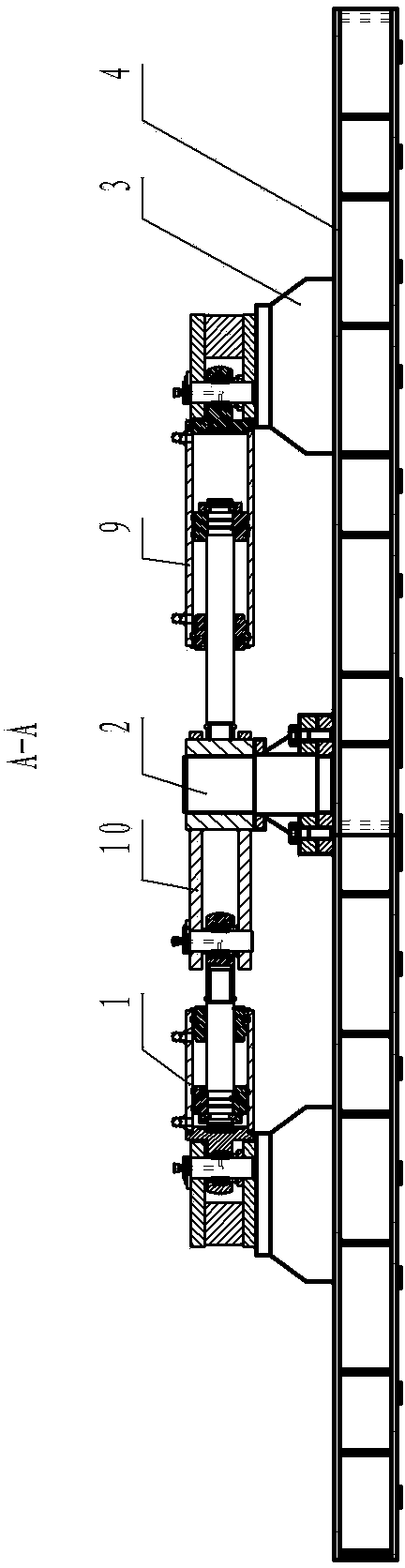

[0011] figure 1 and figure 2 The swing-cylinder hydraulic steering gear test bench shown includes a console 6 and a base 4 that control the entire test bench; two underframes 3 and a tiller base 2 are installed on the base 4; The oil cylinder 1 and the other base frame 3 are provided with two transmission hydraulic cylinders 9; the tiller seat 2 is equipped with a tiller 10, and the two ends of the tiller 10 are respectively hinged with the piston rods of the two transmission hydraulic cylinders 9, and the two transmission cylinders The cylinder body of the hydraulic cylinder 9 is fixedly connected with the underframe 3;

[0012] The handle of the tiller 10 is connected with the loading cylinder 1, and the oil inlet and outlet of the loading cylinder 1 are respectively connected with the loading pump group 8 and the loading oil tank 7; 5 connected.

[0013] When testin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com