Test method of adhesive force of mesh points of light guide plate

A technology of light guide plate outlets and testing methods, which is applied in the testing field and can solve the problems of no testing method, staying at the light guide outlets, poor light guide effect of the light guide plate, uniformity of the surface light source, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

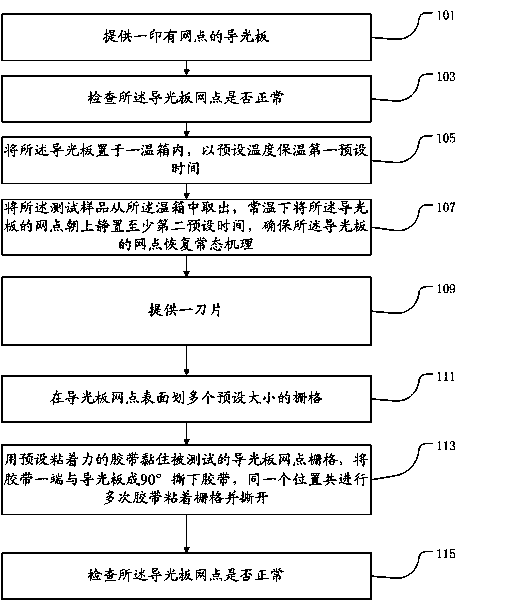

[0027] see figure 1 , a test method for dot adhesion of a light guide plate provided in an embodiment of the present invention. The method includes the following steps:

[0028] Step 101: Provide a light guide plate printed with dots.

[0029] Step 103: Check whether the dots of the light guide plate are normal. In this embodiment, the light guide plate is placed in an environment with an illuminance of 200 lumens, and visually check whether there are any abnormalities such as black spots, missing spots or defects in the dots of the light guide plate, and record them. This step is used for routine quality inspection, to confirm the status of the dots of the light guide plate before the test, and to ensure the validity of the test.

[0030] Step 105: Place the light guide p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com