Bearing structure used for flameproof three-phase asynchronous motor

A three-phase asynchronous motor technology, applied in the field of electric motors, can solve problems such as low life, heating of motor bearings, and damage to operation, and achieve the effects of reliable guarantee, heat generation, and reasonable and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

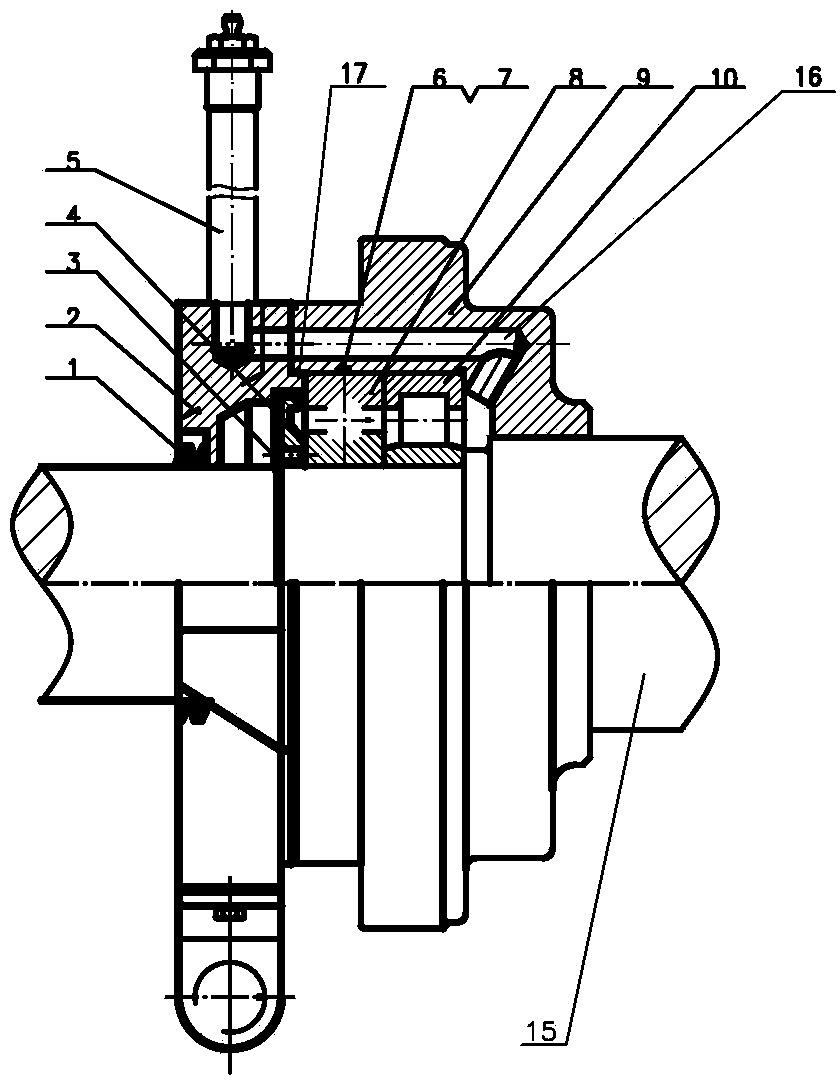

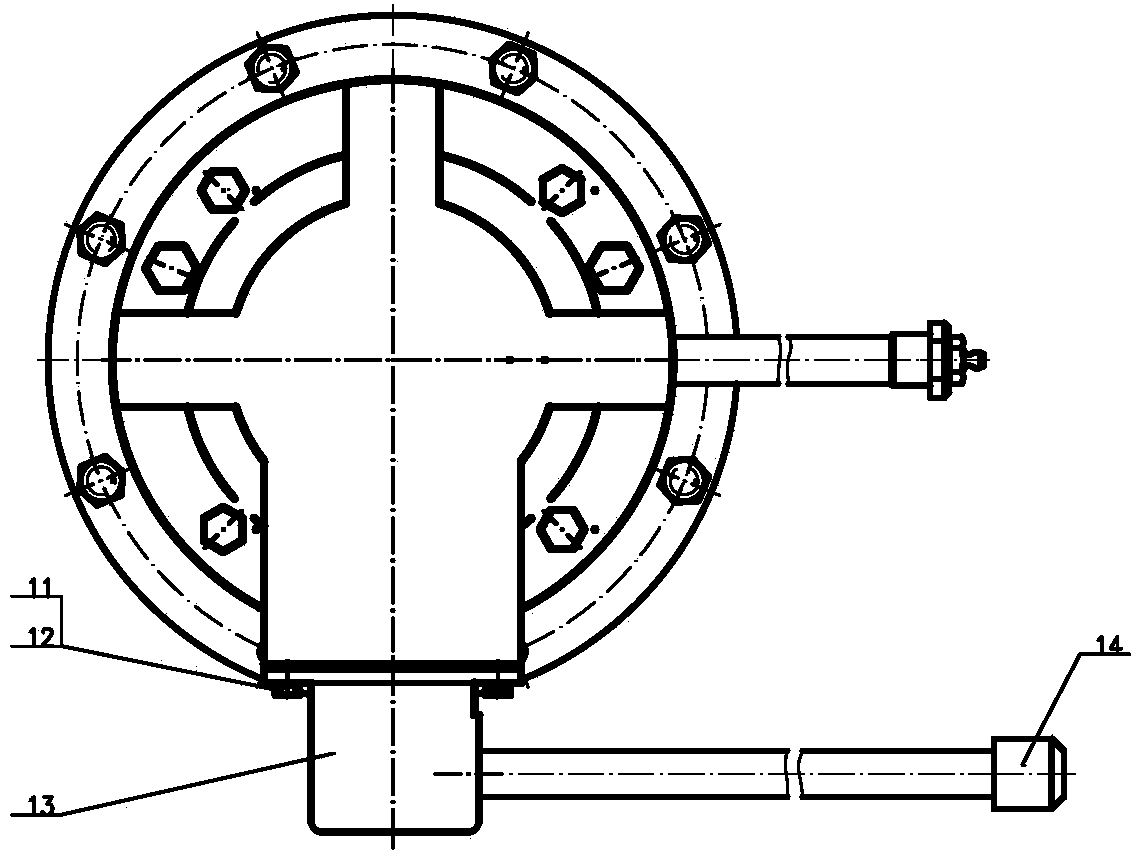

[0014] Such as figure 1 , figure 2 As shown, including rubber sealing ring 1, bearing outer cover 2, elastic retaining ring 3, oil retaining plate 4, oil filling pipe 5, sealing ring 6, neoprene rubber 7, deep groove ball bearing 8, bearing sleeve 9, cylindrical roller Bearing 10, bolt 11, spring washer 12, oil discharge box 13, oil discharge pipe 14, rotating shaft 15, oil groove 16, protrusion 17, etc.

[0015] Such as figure 1 , figure 2 As shown, the present invention is a bearing structure for a flameproof three-phase asynchronous motor, including a rotating shaft 15, and a bearing sleeve 9 is placed on the shoulder of the rotating shaft 15, and the inner cavity of the bearing sleeve 9 is sequentially arranged from inside to outside. Cylindrical roller bearings 10 and deep groove ball bearings 8 are installed, and a bearing outer cover 2 is also inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com