Application of PES (polyether sulfone) microporous membrane in automatic liquid stopper

A technology of microporous film and polyethersulfone, which is applied in the direction of subcutaneous injection devices, etc., can solve the problems of low BP value, slow flow rate, poor hydrophilicity of liquid stop membrane, etc., and achieve safe and convenient infusion process, increase safety and convenience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve polyethersulfone accounting for 10 (wt)% of the total mass in N,N-dimethylacetamide, and add polyvinylpyrrolidone accounting for 8 (wt)% of the total mass, and stir at a temperature of 25°C It is dissolved, passed through a 200-mesh filter, and vacuum degassed to obtain a casting solution. At a temperature of 25°C, the casting solution was scraped on a non-woven fabric to form a 0.2 mm thick liquid film, and left to evaporate in air with a relative humidity of 40% for 30 seconds to initially gel. At a temperature of 40°C, phase inversion is carried out in a gel water bath containing 5 (wt)% of the total mass of N,N-dimethylacetamide to obtain a polyethersulfone microporous membrane.

Embodiment 2

[0027] Dissolve polyethersulfone accounting for 15 (wt)% of the total mass in N,N-dimethylacetamide, and add polyvinylpyrrolidone accounting for 10 (wt)% of the total mass, and stir at a temperature of 50°C It is dissolved, passed through a 200-mesh filter, and vacuum degassed to obtain a casting solution. At a temperature of 40°C, the casting solution was scraped on a non-woven fabric to form a 0.2mm thick liquid film, and left to evaporate in air with a relative humidity of 80% for 120s to initially gel. At a temperature of 40°C, phase inversion is carried out in a gel water bath containing 5 (wt)% of the total mass of N,N-dimethylacetamide to obtain a polyethersulfone microporous membrane.

Embodiment 3

[0029] Dissolve polyethersulfone accounting for 15 (wt)% of the total mass in N,N-dimethylacetamide, and add polyvinylpyrrolidone accounting for 8 (wt)% of the total mass, and stir at a temperature of 40°C It is dissolved, passed through a 200-mesh filter, and vacuum degassed to obtain a casting solution. At a temperature of 20°C, the casting solution was scraped on a non-woven fabric to form a 0.3 mm thick liquid film, and left to evaporate in air with a relative humidity of 60% for 80 seconds to initially gel. At a temperature of 25°C, phase inversion is carried out in a gel water bath containing 5 (wt)% of the total mass of N,N-dimethylacetamide to obtain a polyethersulfone microporous membrane.

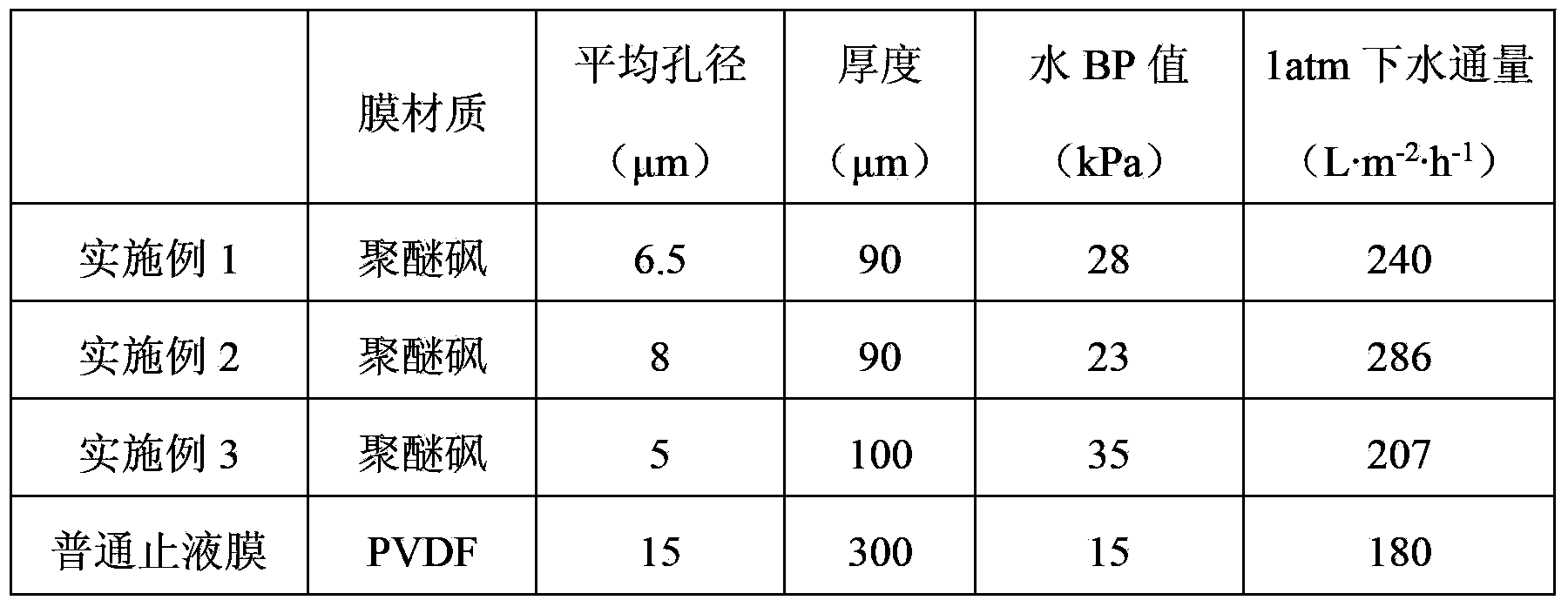

[0030] The polyethersulfone microporous film prepared in Examples 1-3 is cut into a certain shape and then installed in the automatic stop liquid device of the infusion set through ultrasonic welding and other processes, all of which can achieve a good automatic stop liquid functi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com