Optical granular sorting machine

A technology of granular materials and sorting machines, which is used in sorting and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

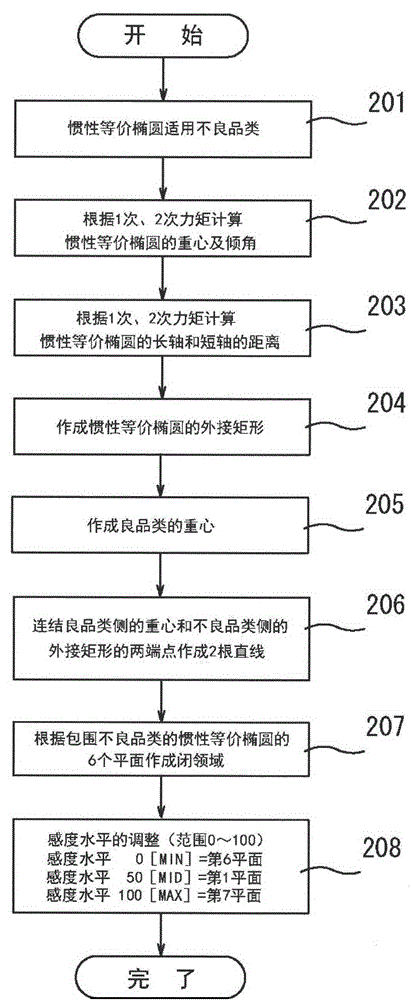

Method used

Image

Examples

Embodiment Construction

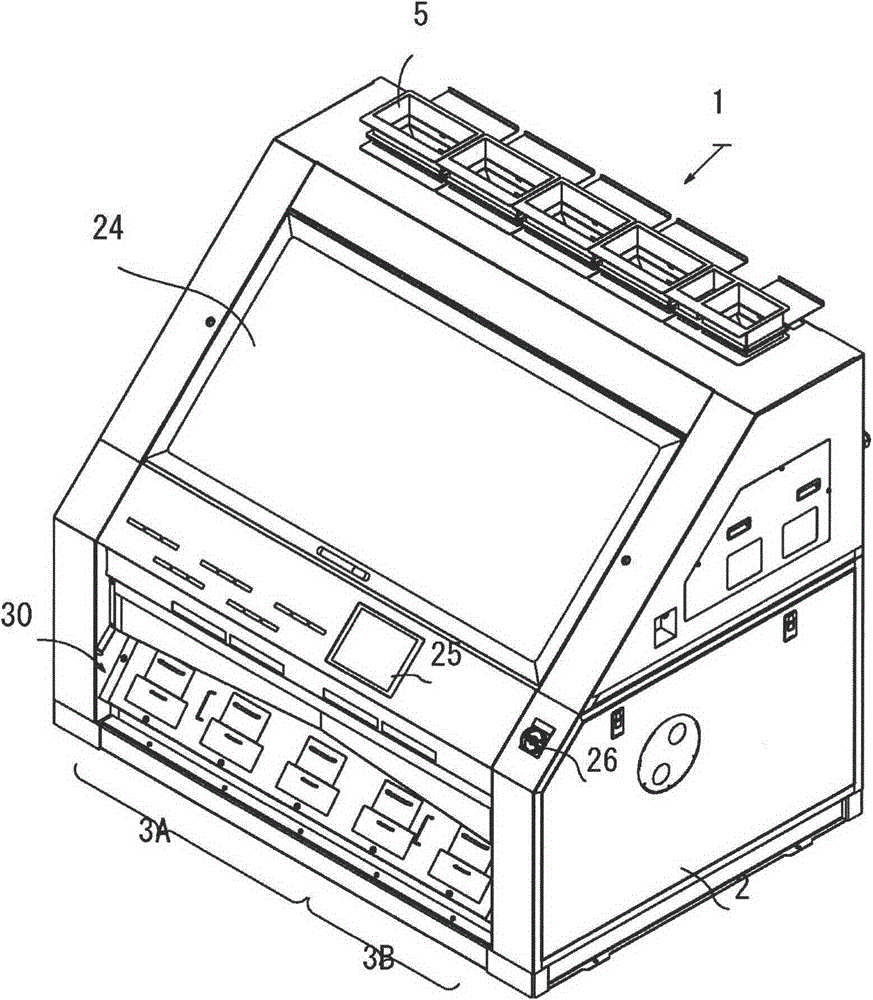

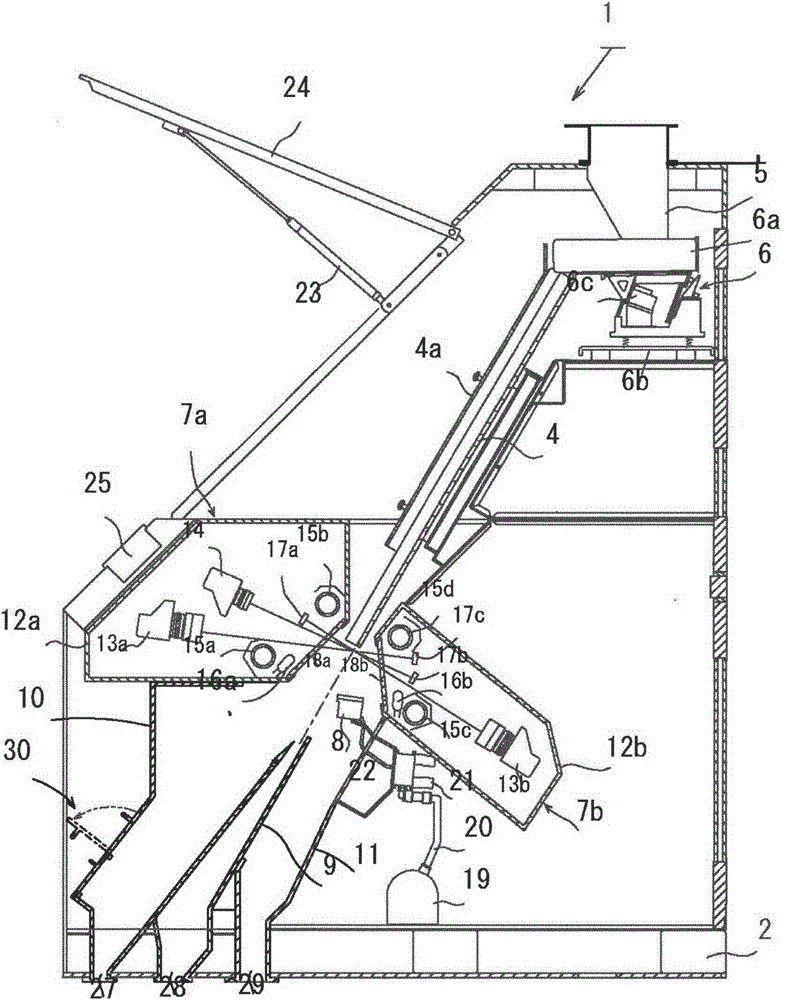

[0027] Aiming at the deficiencies in the prior art, the present invention provides an optical sorting machine for granular objects, which has at least the following functions: for the granular objects containing good products, defective products and foreign objects, the transfer means during continuous transfer; according to the transfer Means, check the inspection means of the aforementioned granular objects that have been transferred; according to the inspection means, according to the color information of the inspected granular objects, it is judged whether it is used as the identification means of the separation object; according to the identification means, the The means of removing the separated objects that have been identified during the continuous transfer process, etc.

[0028] The aforementioned inspection means not only has an illumination unit that illuminates the aforementioned granular objects with passing light; the aforementioned light that can pass through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com