Pressure ware

A pressure device and pressure head technology, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems of inconvenient operation, poor mobility, unfavorable disassembly, etc., and achieve simple assembly, simple working principle, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

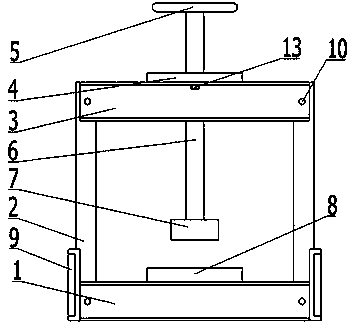

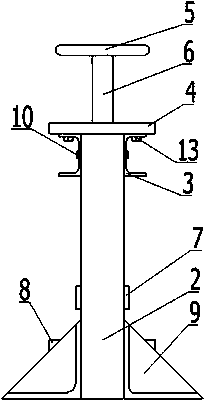

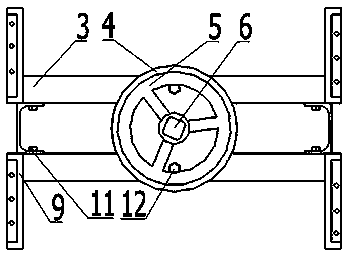

[0016] like Figure 1 to Figure 6 As shown, a pressure device includes a bottom support 1, a vertical support 2 and a support base 9 on both sides of the bottom support 1, an upper support 3 at the top of the longitudinal support 2, a cylindrical spacer 4 above the upper support 3, and a screw rod 6 vertical Through the block 4, its upper and lower ends are respectively connected with the handwheel 5 and the pressure head 7, and the cylindrical platform 8 is directly below the pressure head 7, and the platform 8 is fixed on the bottom support 1. The bottom support 1, the longitudinal support 2 and the upper support 3 are made of channel steel, and the bottom support 1 is channel steel with two notches facing each other and placed in parallel at intervals. There are two longitudinal supports 2 in the interval, and the upper support 3 is also composed of two It is composed of channel steel with opposite notches and spaced in parallel. The support base 9 is four triangular steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com