A power steering tie rod

A technology of power steering gear and tie rods, which is applied in the direction of steering rods, steering mechanisms, vehicle components, etc., can solve problems such as potential safety hazards, prone to fatigue fractures, and reduce steering sensitivity of steering gears, so as to prolong the failure time and improve potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

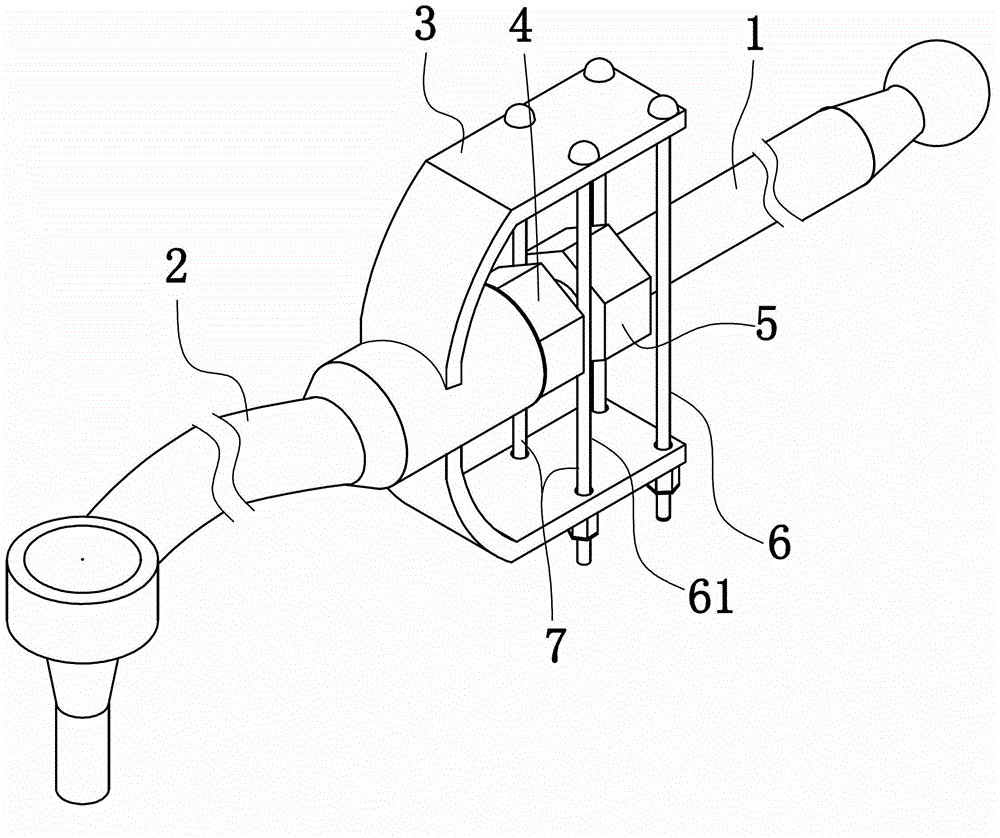

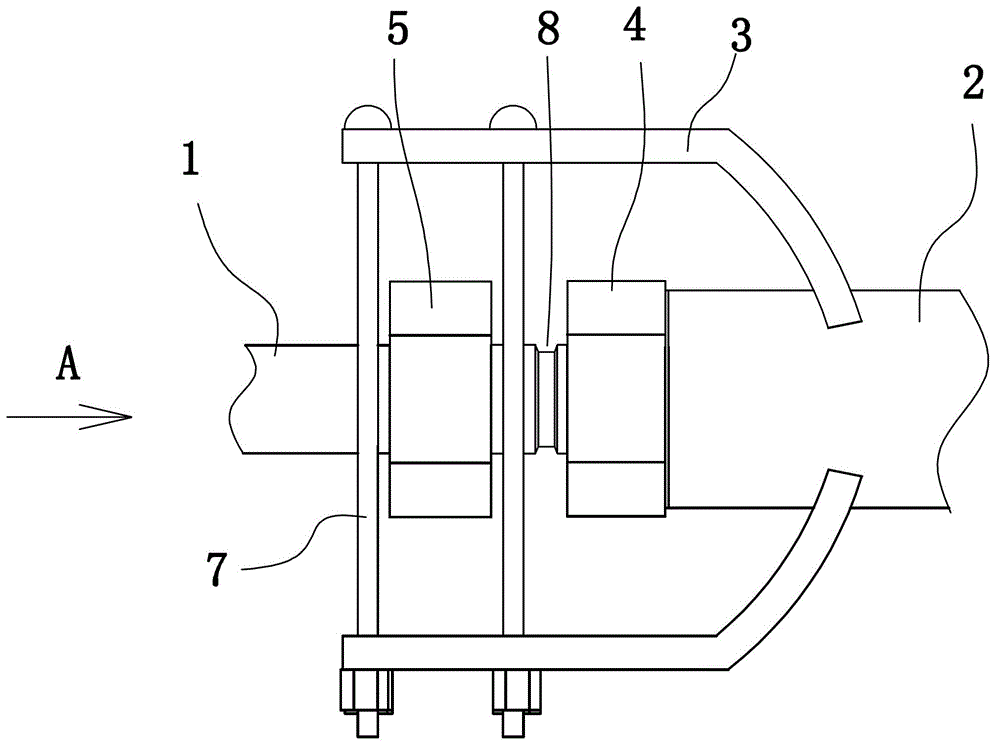

[0021] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a power steering tie rod is composed of an inner tie rod 1 and an outer tie rod 2 spliced together. The splicing structure between the inner tie rod and the outer tie rod includes a threaded connection hole arranged on the end surface of the outer tie rod 2, an outer thread arranged at one end of the inner tie rod 1 and a pre-tightening fixing nut 4 arranged on the outer thread. The threaded connection holes of the inner tie rod 1 and the outer tie rod 2 are connected by threads. The pre-tightening fixing nut 4 is tightened so that its end is pressed against the end face of the outer tie rod 2 . The splicing structure between the inner tie rod and the outer tie rod can also be connected by welding to the inner tie rod and the outer tie rod.

[0022] An annular blocking projection 5 is provided on the inner tie rod 1 near the splicing part of the inner tie rod 1 and the outer tie rod 2 . The annular blocki...

Embodiment 2

[0025] Embodiment 2: the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

[0026]An annular blocking projection is arranged on the outer tie rod, near the splicing part of the inner tie rod and the outer tie rod. A pair of supporting arms are arranged on the inner tie rods and near the splicing part of the inner tie rods and the outer tie rods, which are relatively distributed on both sides of the tie rods and extend toward the direction of the other tie rods. The two supporting arms are distributed on opposite sides of the annular blocking projection, and the two supporting arms close to the annular blocking projection are parallel to the inner tie rod.

Embodiment 3

[0027] Embodiment 3: the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

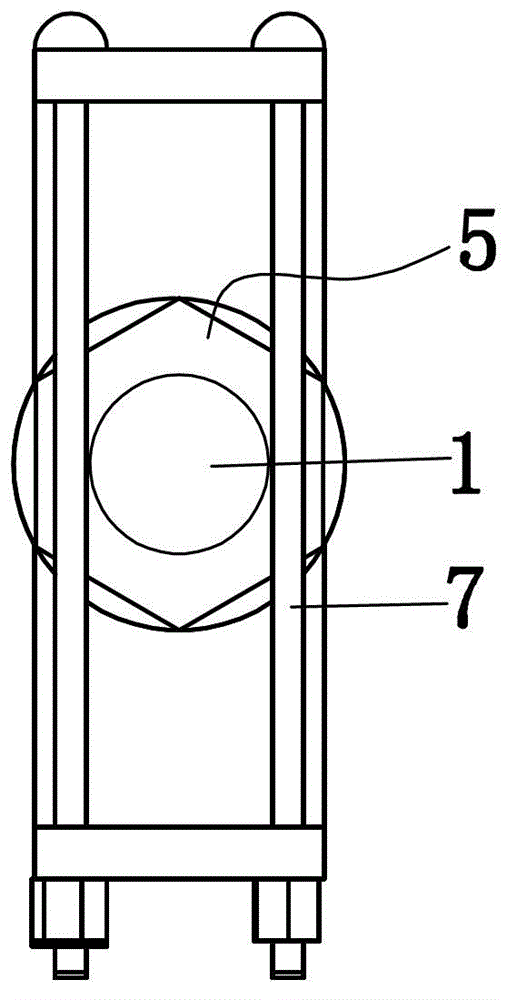

[0028] Such as Figure 4 As shown, between the two supporting arms 3 , there are stoppers 6 and 61 respectively located at both ends of the annular blocking projection. On the two retaining frames 6,61, there are respectively a pair of retaining rods 7 located on the inside of the end face of the annular blocking projection. The end surfaces are parallel, and a through hole is provided in the middle of the baffle plate, and the inner tie rod 1 is inserted into the through hole; the pair of baffle rods on the above-mentioned baffle frame are the baffle plates on both sides of the through hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com