A multi-purpose air-expanding chuck and its working method

A chuck and air expansion technology, applied in the field of printing equipment, can solve the problems of affecting work efficiency, time-consuming and laborious, inapplicability, etc., and achieve the effects of stable tensioning force, reliable tensioning, and convenient switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

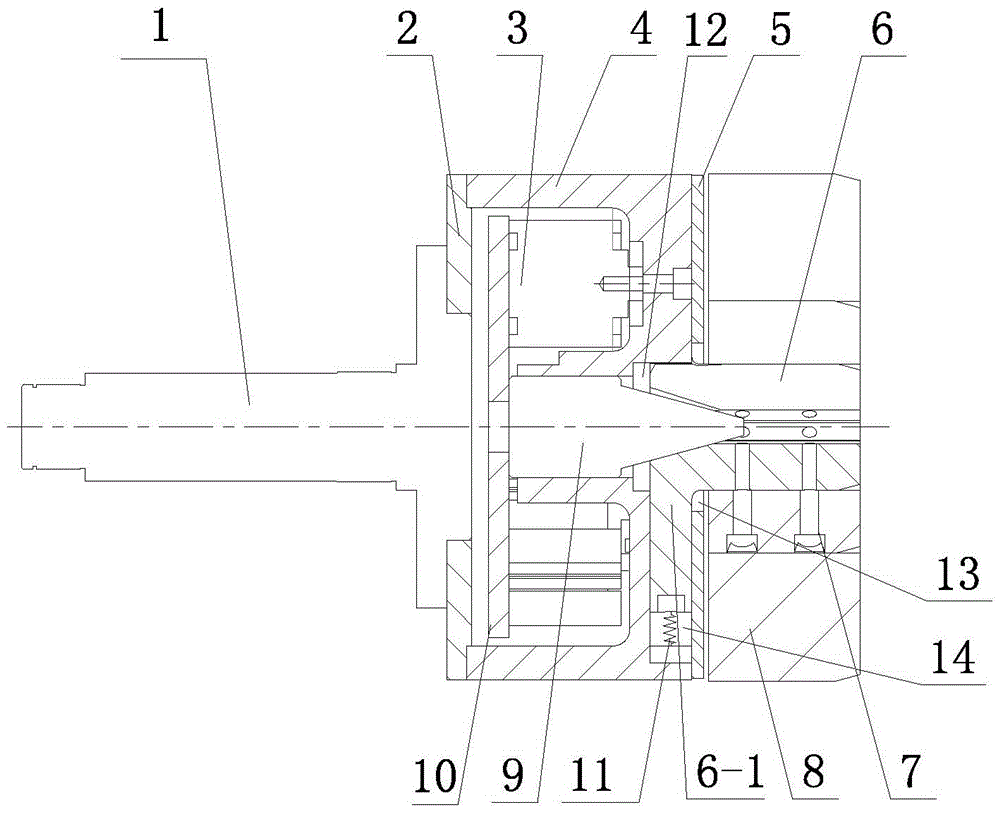

[0022] Embodiment: a multi-purpose air-expanding chuck (see attached drawing), which is characterized in that it includes a power shaft 1, a cylinder 3, a top cone 9 and a small shaft expansion piece 6; one end of the power shaft 1 is connected to a power source, and the other One end is fixedly connected with the cylinder jacket; the cylinder 3 is placed in the cylinder jacket, one end of the cylinder 3 is fixedly connected with the cylinder jacket, and the other end is connected with the top cone 9; the cone surface of the top cone 9 is fitted with several small shaft expansion pieces 6.

[0023] The cylinder jacket includes a cover plate 2 and a cylinder liner 4, one end of the cover plate 2 is fixedly connected to the power shaft 1, and the other end is fixedly connected to the cylinder liner 4; the cylinder liner 4 is provided with a cavity, which is symmetrical Place several cylinders 3; one end of the cylinder 3 is fixedly connected to the cylinder liner 4, the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com