A defoaming device and method for cleaning cold-rolled strip steel

A technology of cold-rolled steel strip and defoaming device, which is applied in the direction of foam dispersion/prevention, etc., can solve the problems of high cost, damage to the tightness of steel plate and coating or coating, etc., achieves low cost, avoids quality defects, and the method is simple and easy row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

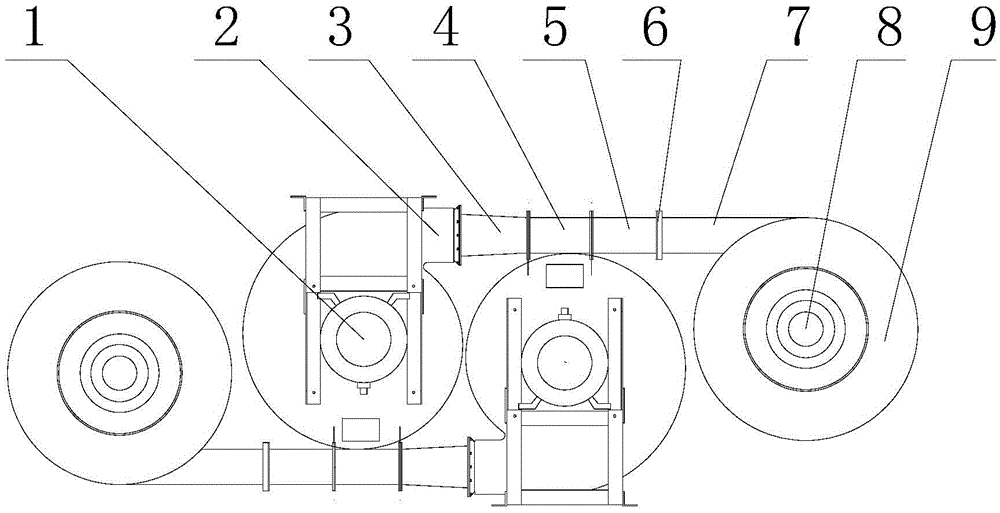

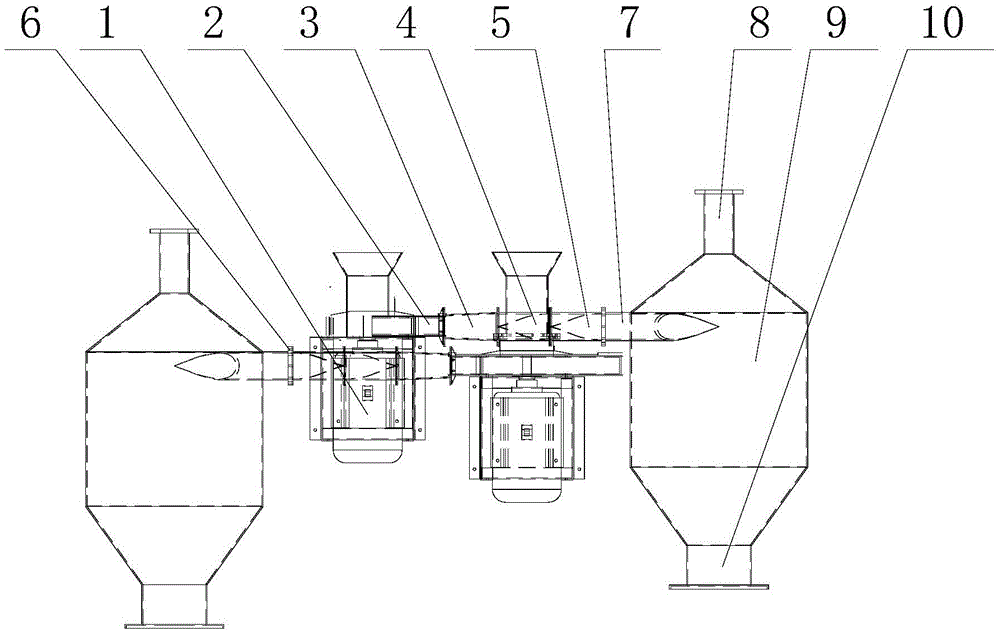

[0024] As can be seen from the accompanying drawings, the defoaming device for cleaning cold-rolled steel strip of the present invention consists of a foam-absorbing pump 1, a connecting pipe 3, a left-handed defoaming pipe 4, a right-handed defoaming pipe 5, a defoaming gasket 6 and a gas-liquid separator Composed of 9.

[0025] The bubble pump 1 includes a motor and a vane pump. The vane pump is designed according to the structure of a conventional centrifugal fan. One side of the vane pump is provided with a bubble pump exhaust pipe 2. The diameter of the inlet is 180mm, and the flow rate is 1978m3 / h. 3050Pa. The power of the motor is 3KW, and the speed is 2960rpm.

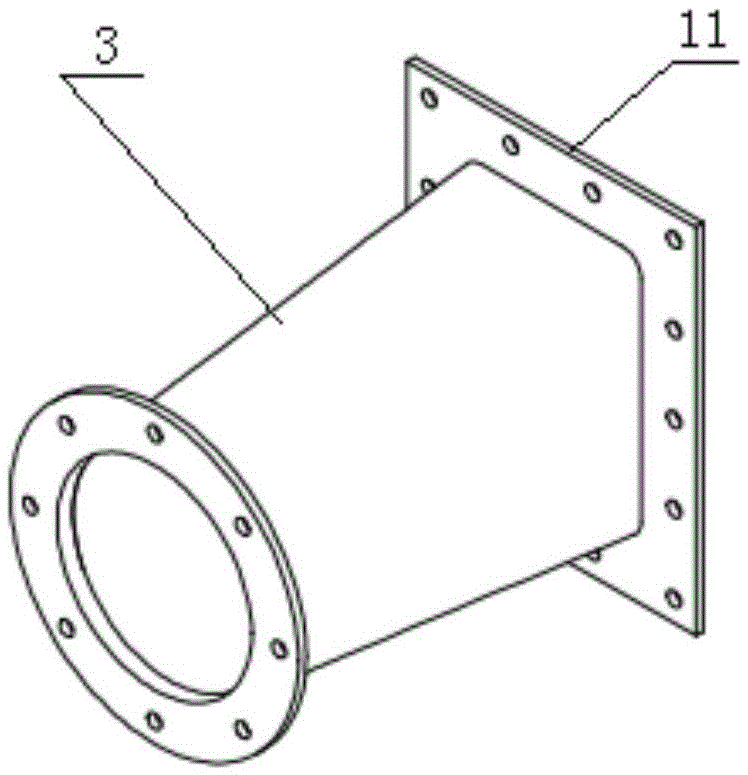

[0026] Connecting pipe 3 one end is big, and one end is small, and big end is square, and has a square flange 11, and small end is circular, has round flange. The left-handed defoaming pipe 4 is a cylinder with round flanges at both ends of the cylinder. A left-handed helical piece 12 is housed in the left-ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com