Method for connecting rigid body and flexible body of dam foundation of reservoir

A connection method and rigid body technology, which is applied in water conservancy projects, sea area projects, buildings, etc., can solve problems such as inconvenient implementation, firmness of connection, insufficient tightness, poor anti-seepage effect of reservoir dam foundation, etc., and achieve good tightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0023] The connection method between the rigid body and the flexible body of the reservoir dam foundation of the present invention adopts the lap joint method, and the slot hole of the thin concrete cut-off wall at the lap joint is set as a second-stage slot hole. When the thin concrete cut-off wall is poured and constructed, the steps are as follows :

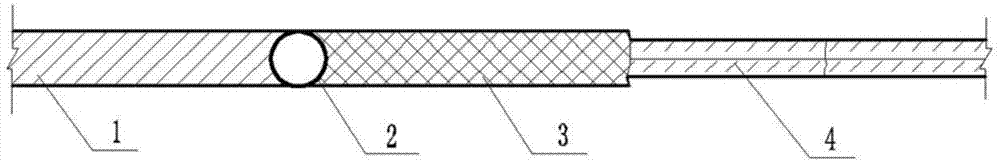

[0024] First, refer to figure 1 , all the first-stage slots 1 and second-stage slots 3 of the thin concrete anti-seepage wall section are opened, and the concrete pipe 2 is buried at the transition between the first-stage slot 1 and the second-stage slot 3, and then the first-stage slot The first stage concrete 5 is poured in the hole 1.

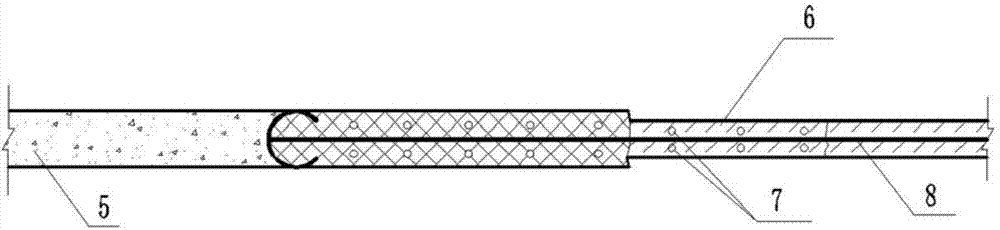

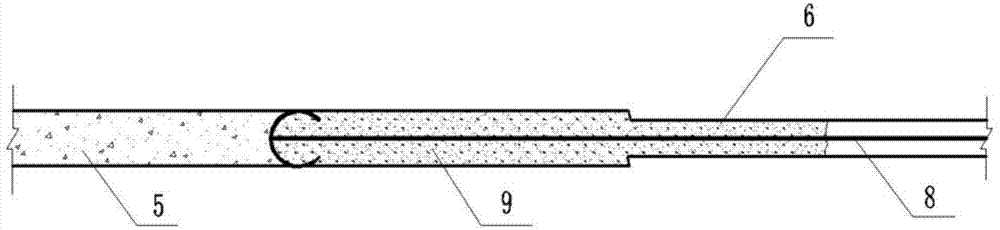

[0025] Second, refer to figure 2 , when the first-stage concrete 5 of the thin concrete cut-off wall section reaches its strength, use a percussion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com