Shear wall mold board external corner counter-pulling device

A shear wall and formwork technology, which is applied to the field of shear wall formwork positive angle tension devices, can solve the problems of poor reinforcement of the shear wall positive angle position, shear wall structure expansion, waste of concrete materials, etc. The effect is good, the overall strength and stiffness are strengthened, and the effect of improving the pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

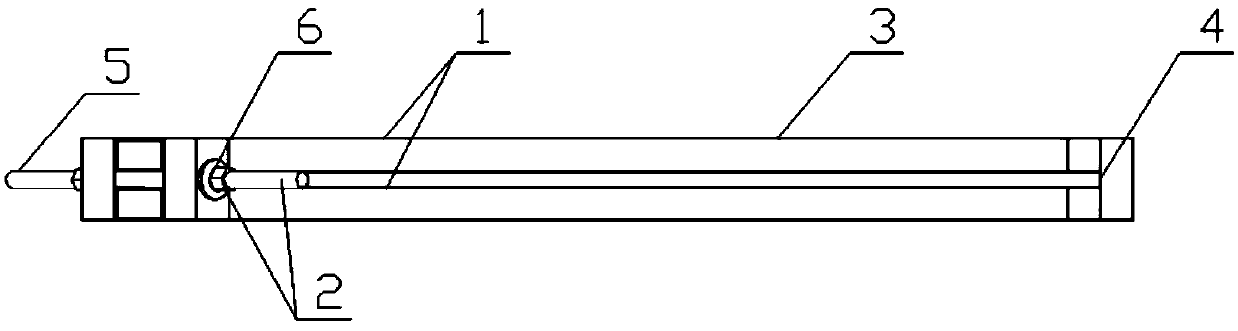

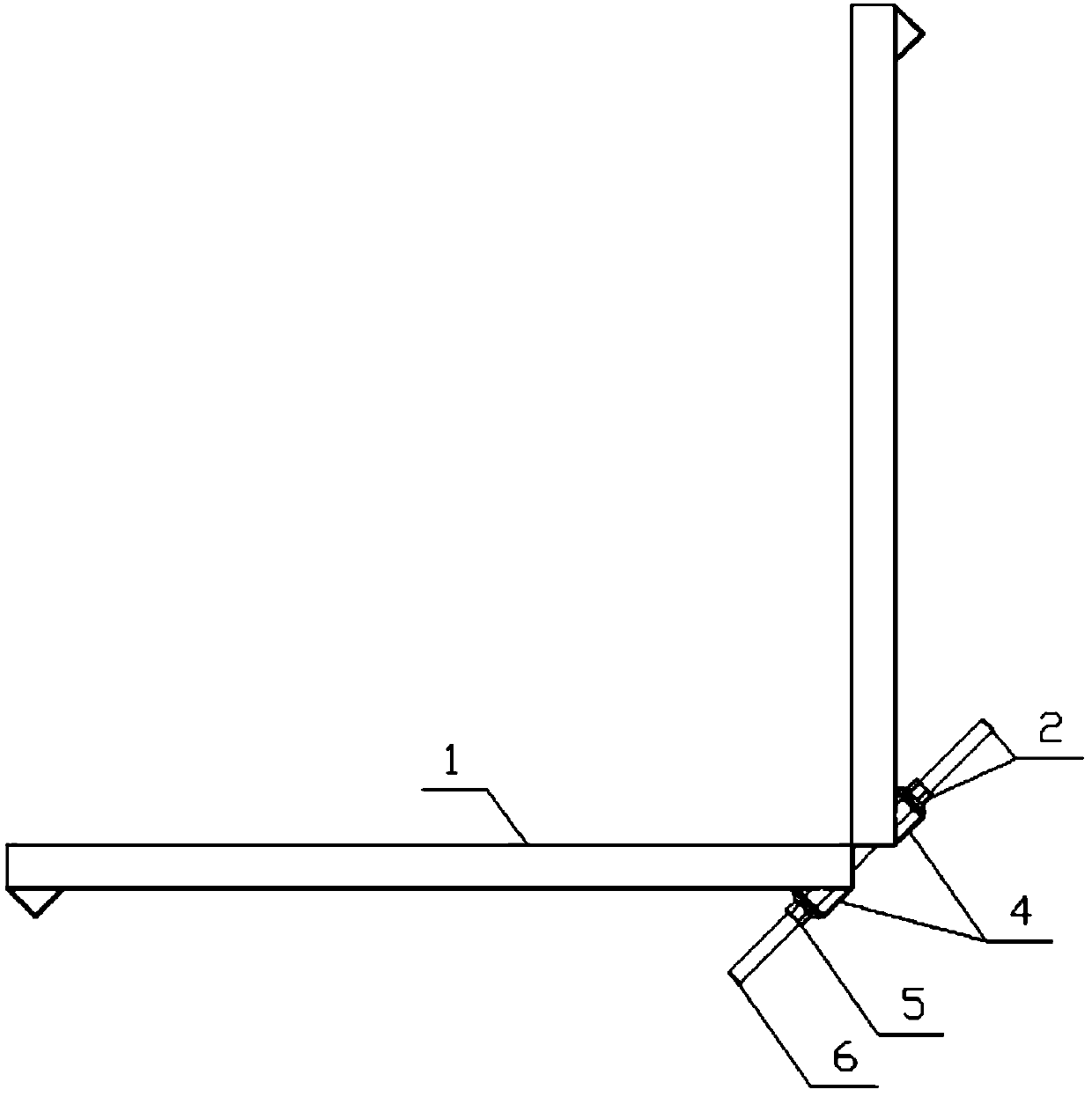

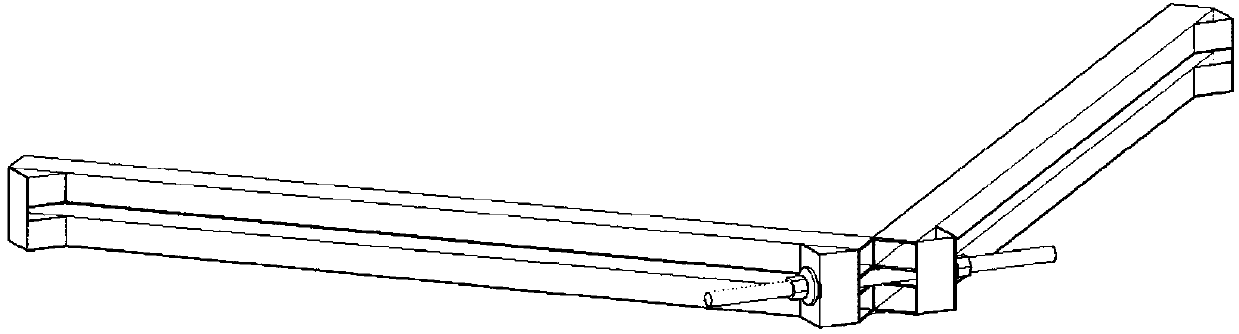

[0019] Such as figure 1 and figure 2 As shown, it is a shear wall formwork male corner tensioning device provided by the embodiment of the present invention, which includes a horizontal back flute 1 and a tension screw device 2, and the horizontal back flute 1 includes two mutually perpendicular flute bodies 3 , so that the horizontal back corrugated 1 is L-shaped, and the two corrugated bodies 3 are respectively fixed on the aluminum alloy templates on both sides of the male corners, and a steel plate seat 4 is fixedly installed on the ends of the two corrugated bodies 3 close to the male corners. The pull screw device 2 includes a screw 5 and a circular washer-type hexagonal nut 6. The screw 5 is sequentially interspersed in two steel plate seats 4 to connect the two steel plates, and a circular washer-type hexagonal nut is respectively arranged at both ends of the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com