Chocolate syrup pump

A technology of chocolate slurry and pump body, which is applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of unstable slurry feeding, high blade speed, easy to damage the quality of slurry, etc., and achieves compact and reasonable structure, fault maintenance The effect of low efficiency and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

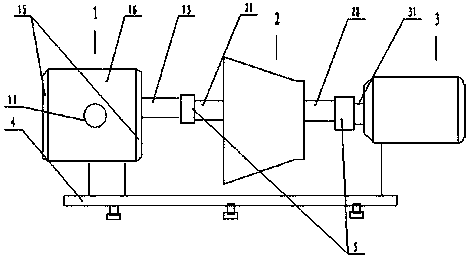

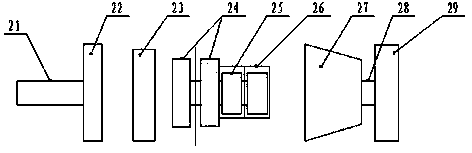

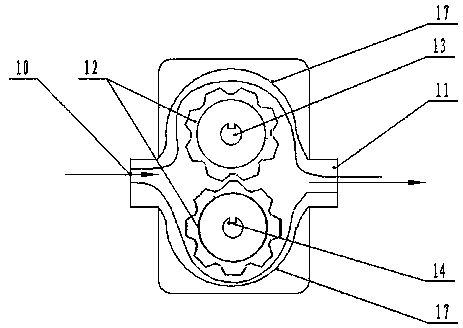

[0015] see figure 1 , figure 2 and image 3 , the embodiment of the present invention includes:

[0016] A kind of chocolate slurry pump, comprises gear pump 1, cycloidal pinwheel speed reducer 2, motor 3 and frame 4, and described gear pump 1 comprises pump cover 15, pump body 16 and a pair of meshing gear 12, and described pump The cover 15 is located on the front and rear sides of the pump body, and the pair of meshing gears 12 are composed of a driving gear and a driven gear, are located inside the pump body 16, and are fixed on the pump covers on both sides of the pump body by the gear shaft. The body is provided with a material inlet 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com