Low-noise high-firepower combustor

A low-noise, burner technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of high combustion noise, lack of firepower of gas stoves, and insufficient flame height, so as to reduce combustion noise, save gas, The effect of reducing turbulence phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

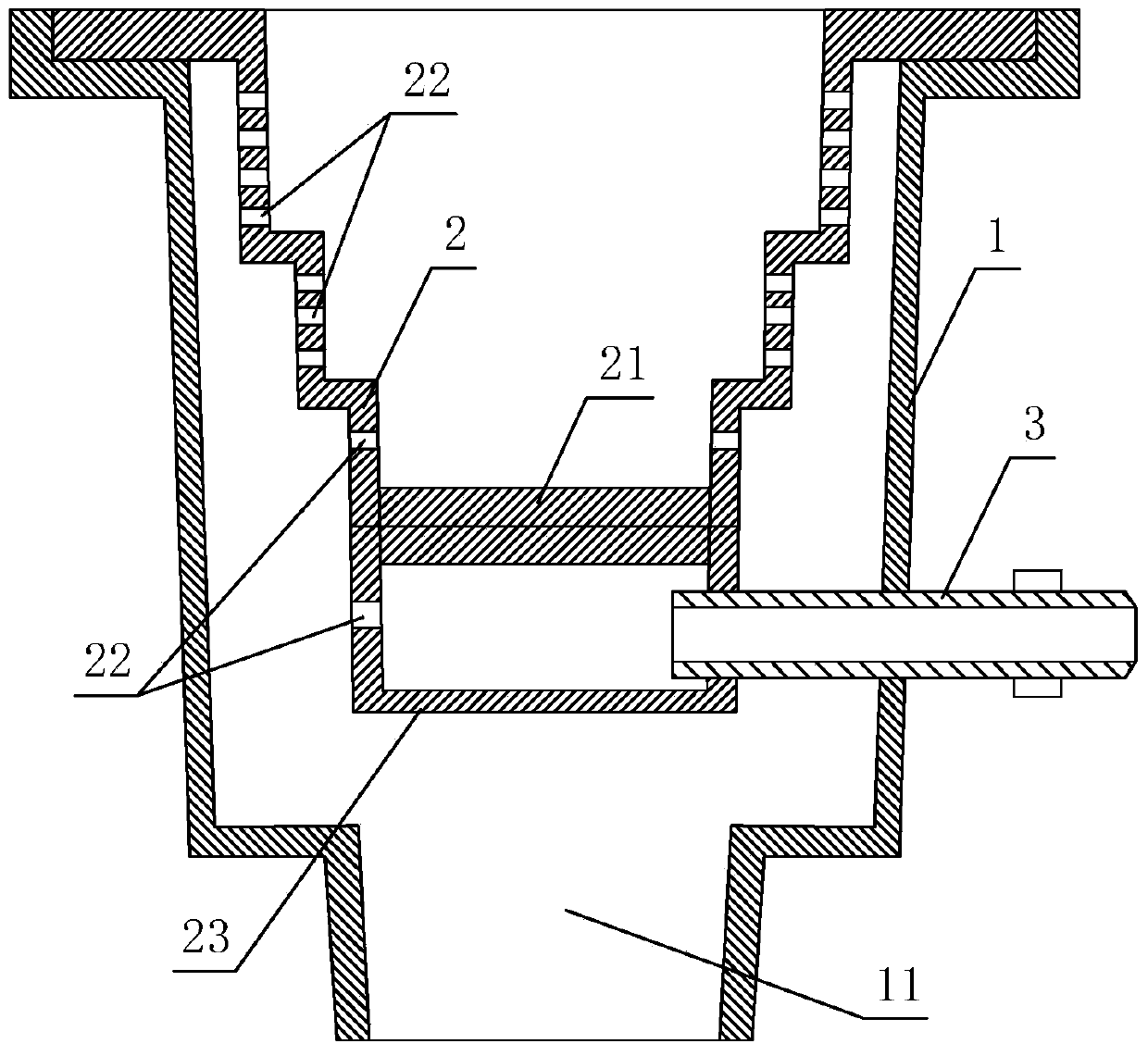

[0010] Such as figure 1 As shown, a burner with low noise and strong firepower includes a cylindrical outer shell 1 and a cylindrical inner shell 2, the inner shell 2 is set inside the outer shell 1, the top of the outer shell 1 and the top of the inner shell 2 are closed and connected, and the outer shell 1 A sandwich cavity is formed between the inner shell 2, the bottom of the outer shell 1 is provided with an air inlet 11, the bottom 21 of the inner shell 2 is sealed, and the inner cavity of the inner shell 2 is set to be at least two or more stages enlarged step by step from bottom to top. The above steps are in the shape of steps, and the side walls in the length direction of each step are provided with ventilation holes 22 all over. Specifically, the stepped inner cavity of the inner shell 2 is arranged in three stages, and the number of ventilation holes 22 in each stage increases step by step from bottom to top.

[0011] In this embodiment, the side wall of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com