Total station networking measurement method of large-scale structural component

A technology of large-scale structural parts and total station, which is applied in the direction of measuring devices, measuring instruments, instruments, etc., can solve the problems of large transmission error, waste, and inability to guarantee accuracy, and achieves a large measurement range, avoids waste, and improves measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

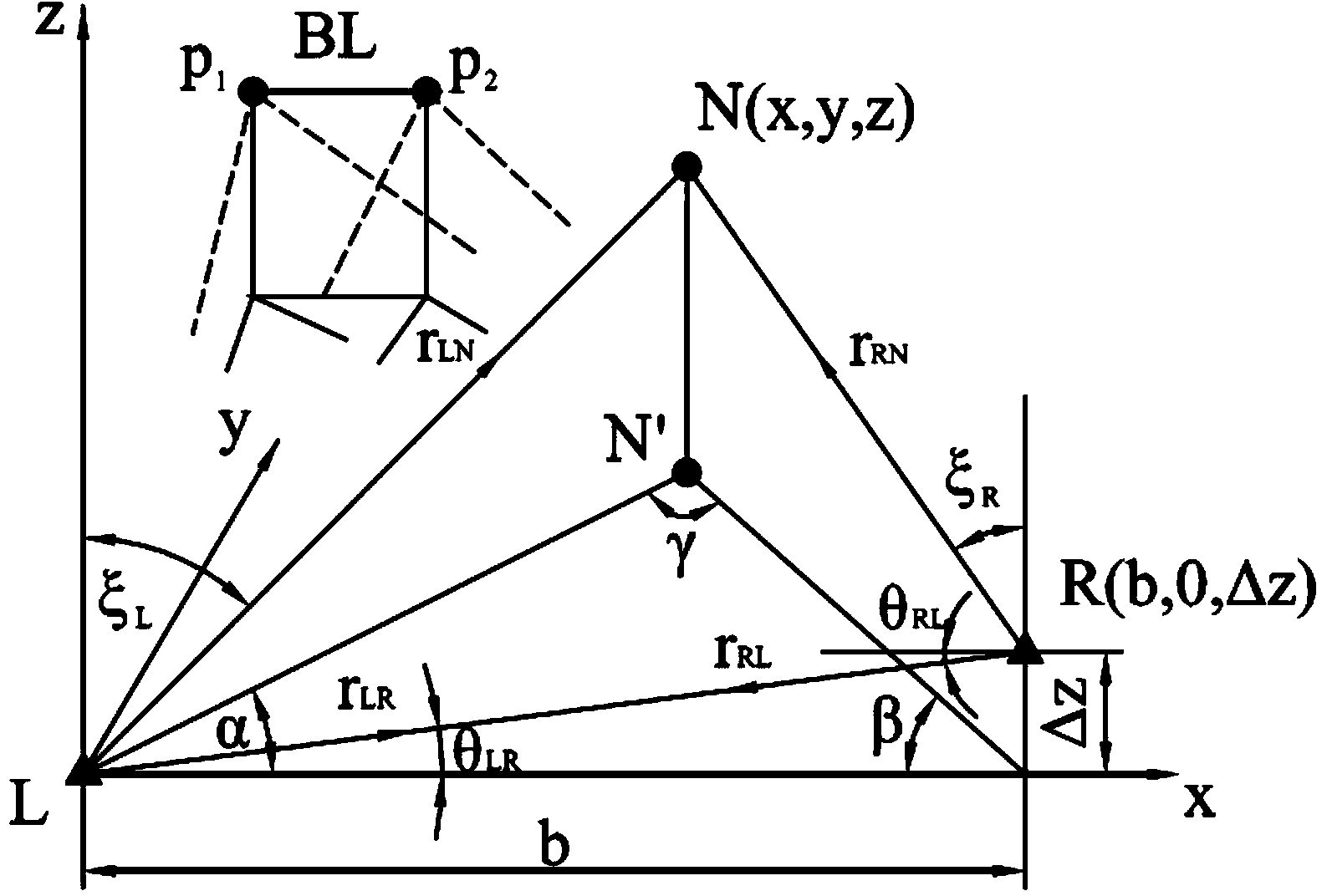

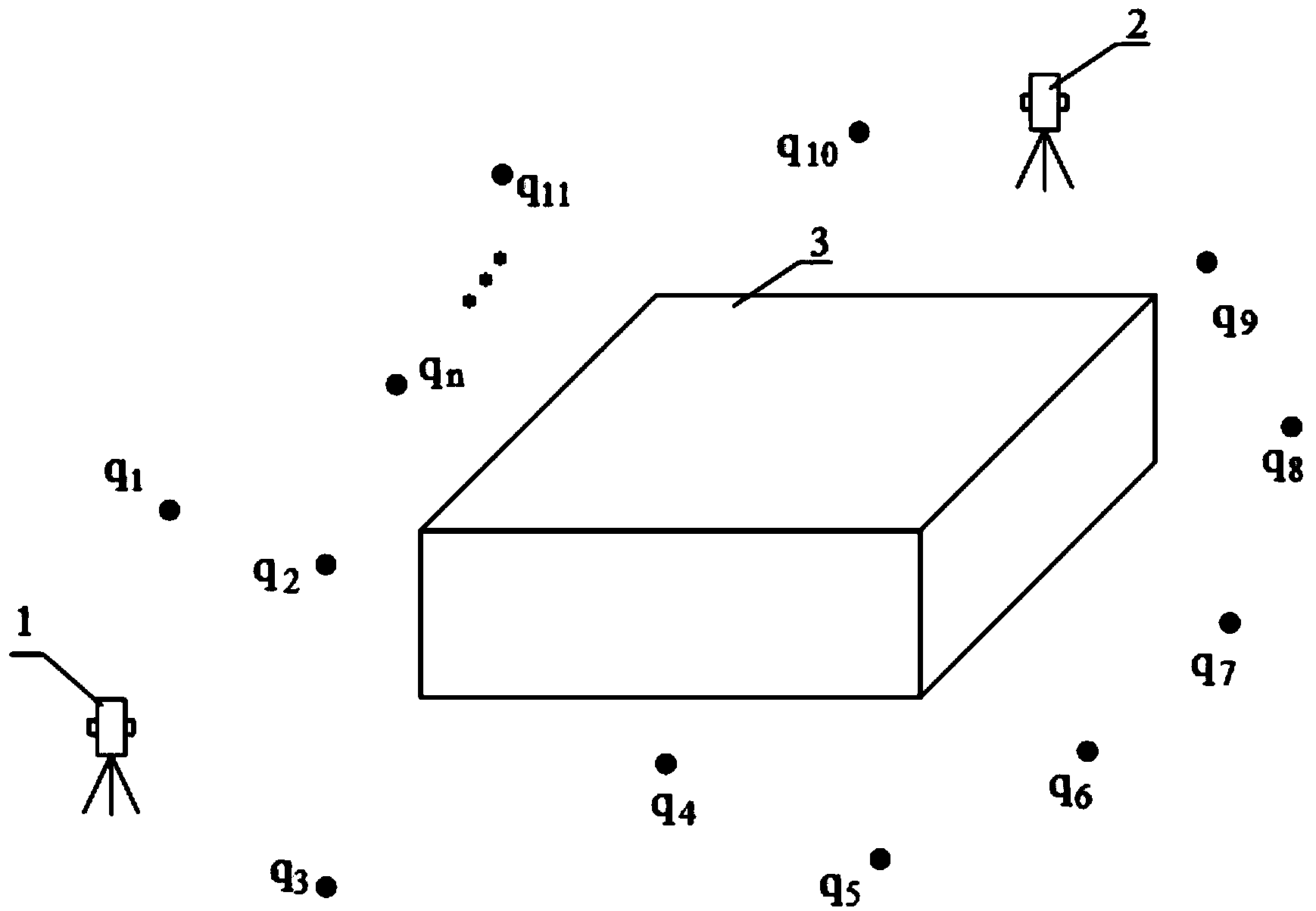

[0024] Its specific scheme of the method for measuring large structural parts by total station network of the present invention is as follows, see image 3 as shown,

[0025] (1) Before measurement

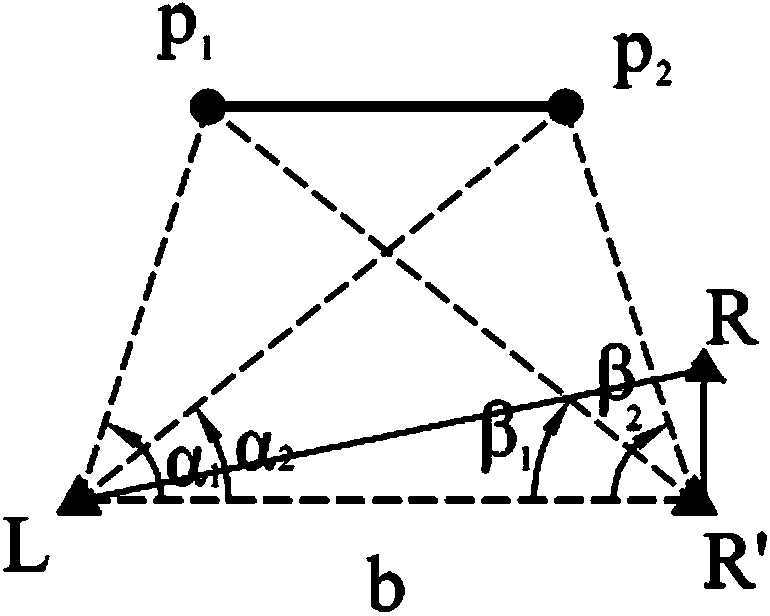

[0026] Set the main station total station 1 and the auxiliary station total station 2 on both sides of the large structural part 3 to be measured; determine three measuring points on the large structural part 3, and place a positioning prism, according to the three measuring points and passing Determine the user coordinate system of the main station by the method of surface-line-point; determine several reference points q between the total station 1 of the main station and the total station 2 of the auxiliary station, and around the large structural part 3 1 ...q n , and place the positioning prisms one by one, the reference point q 1 ...q n Include the master station user coordinate system, use six or more of them as the reference points for setting up stations, and measure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com