Structure of changing composite-material electronic product shell deformation degree

A technology of composite materials and electronic products, applied in the direction of electrical equipment casings/cabinets/drawers, electrical components, etc., can solve the problems of electronic product quality impact, deformation that cannot effectively meet actual needs, deformation, etc., and achieve light weight and high strength , Thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

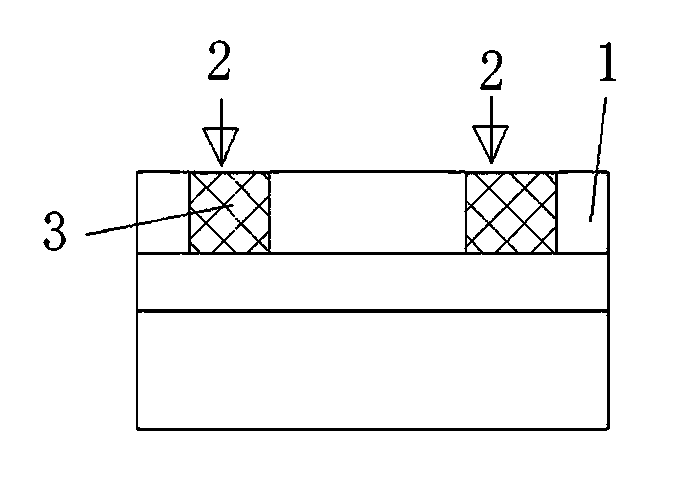

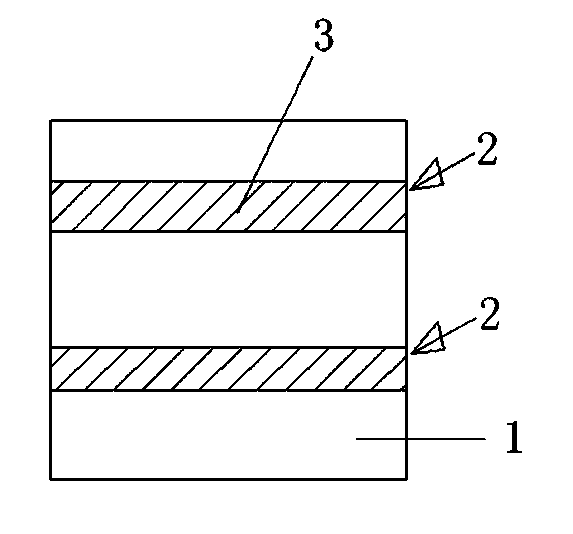

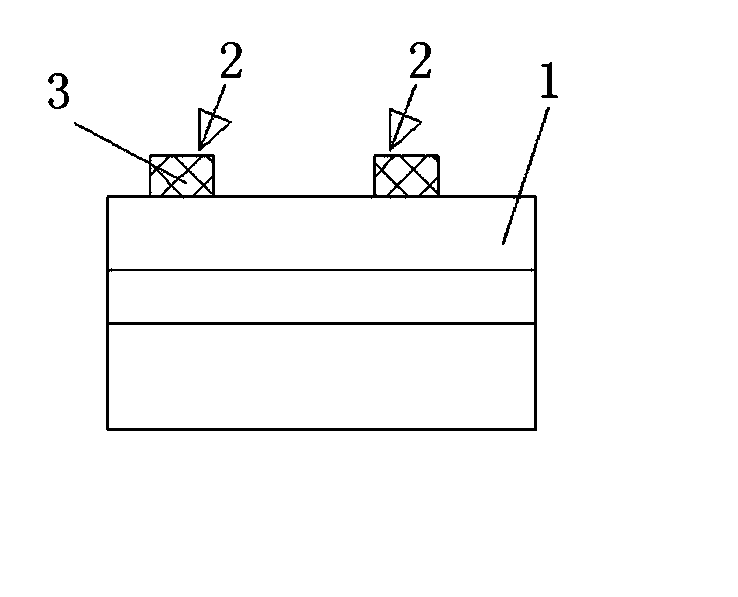

[0019] like figure 1 , figure 2 and image 3 As shown, a structure for changing the degree of deformation of a composite electronic product casing includes a composite material layer 1, and several deformation devices 2 for setting deformation directions are arranged on the composite material layer, so that the deformation device can make The degree of deformation of the composite material layer is reduced or increased.

[0020] Preferably, the deformation device 2 is relatively fixedly bonded to at least one of the interior and the surface of the composite material layer 1 , and at this time, the deformation device 2 can be exposed to the surface or be flush with the surface.

[0021] Preferably, the composition of the deformation device 2 is: a deformation piece 3 with a contraction direction opposite to the contraction direction of the composite material layer 1 is provided, and the deformation piece 3 is embedded in the interior and surface of the composite material lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com