Peanut picking and harvesting test bench

A test bench and peanut technology, applied in the field of machinery, can solve the problems of inaccurate test data, rough structure, and many factors affecting test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiments.

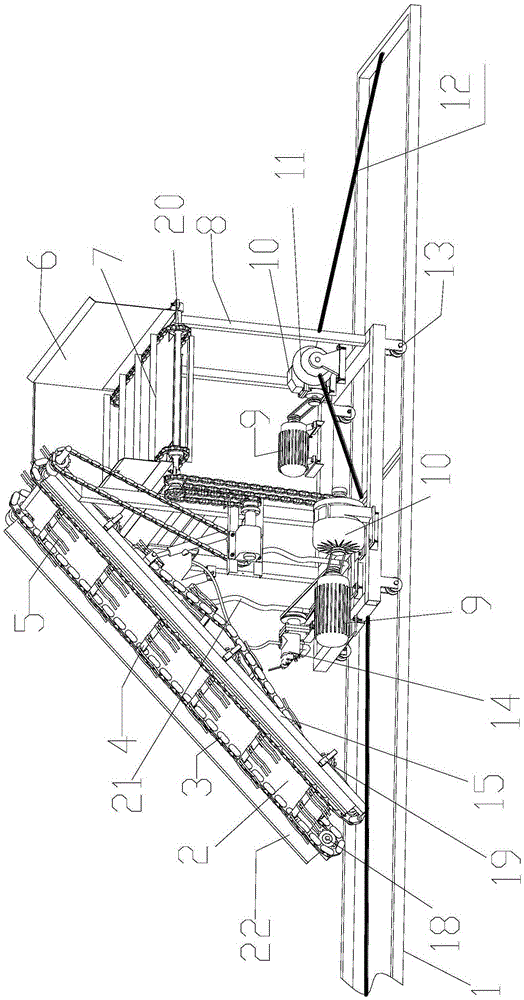

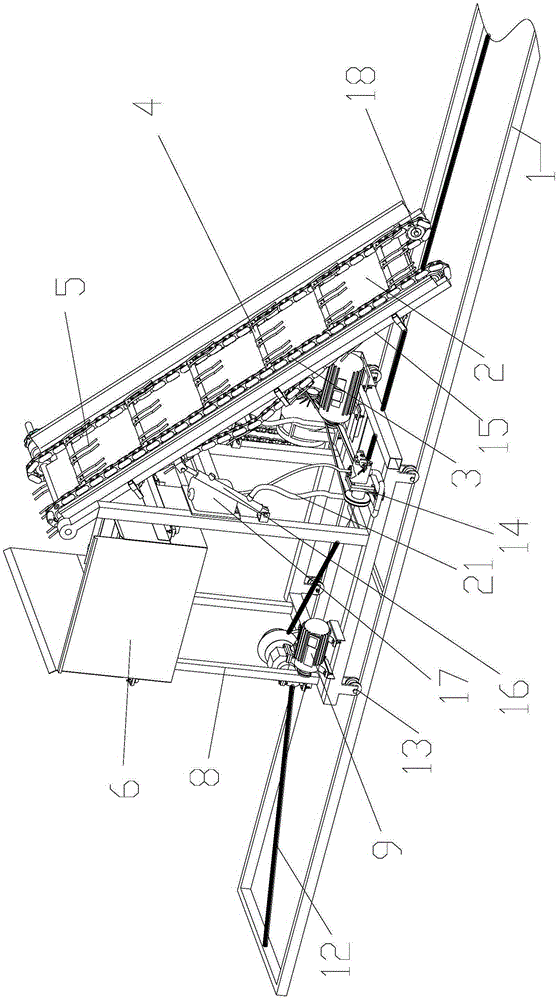

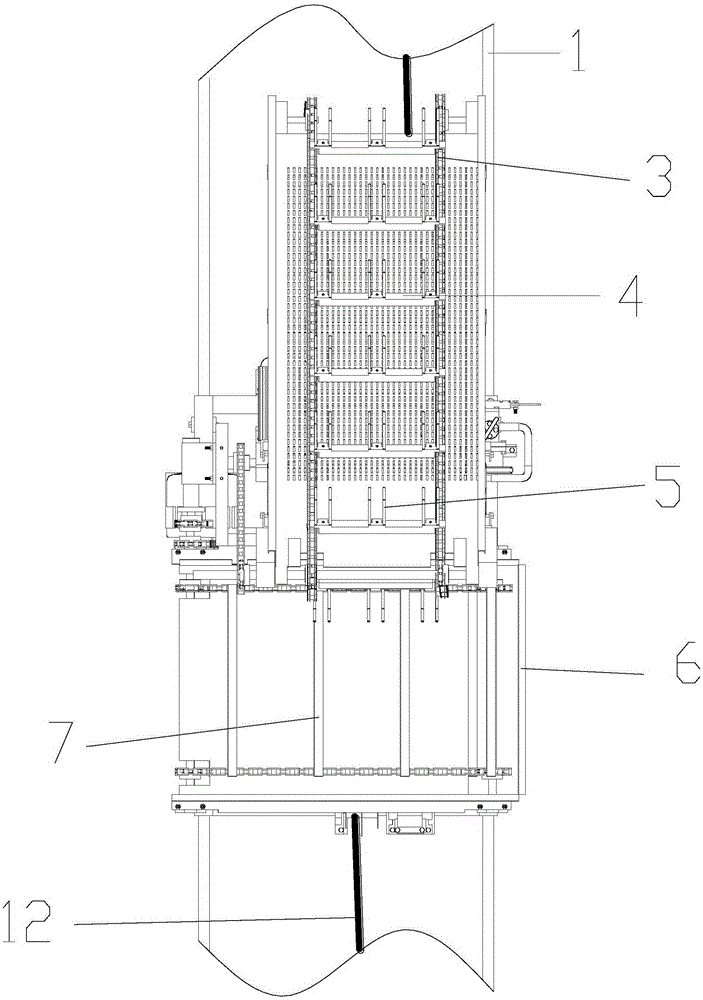

[0026] Depend on Figure 1-3 As can be seen from the shown peanut picking and harvesting test bench, it includes a collecting device and a power output device, and it also includes a hydraulic device, a spring tooth picking up conveying device and a walking device. Wherein, the collection device includes a bracket 8 and a collection box 6 located above the bracket 8, the bottom of the collection box 6 is provided with a scraper 7, and the scraper 7 is connected to the power output device through a conveyor chain 20, and the distance between the scrapers 7 is 250- 350mm, the moving direction of the scraper 7 points to one side of the opening of the collection box 6 . The power take-off device includes a motor 9 and a gearbox 10 located below the collection box 6 and the spring tooth picking-up conveying device. Among them, there are two sets of power output devices, and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com