Forming equipment of spiral pipe with special section and forming method

A technology of special-shaped section and forming equipment, applied in the field of machining, can solve the problems of poor section accuracy, uneven pitch, poor section forming, etc., achieves low investment, solves uneven pitch and poor section forming, and has strong practical value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

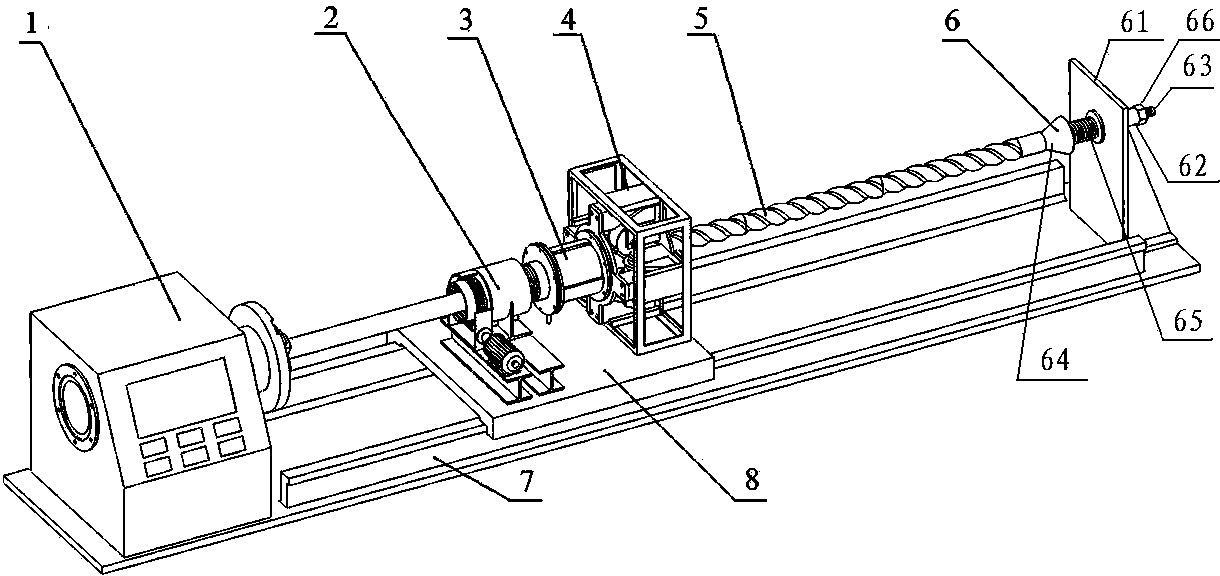

[0026] like figure 1 As shown, a special-shaped section spiral tube forming equipment, one end of the equipment is equipped with a spindle box 1 containing a chuck, and the other end is equipped with a pipe end clamping seat 6. The sliding plate 8 is installed on the sliding rail 7, and the spindle box 1 drives the sliding plate 8 to move back and forth at a given speed through a lead screw or other transmission mechanism. The sliding plate 8 is provided with an axial pushing mechanism 2 , a tube heater 3 and a radial pressing mechanism 4 . One end of the workpiece 5 (round pipe) is fixed with the chuck of the spindle box 1 , and the other end is fixed with the pipe end jacking seat 6 .

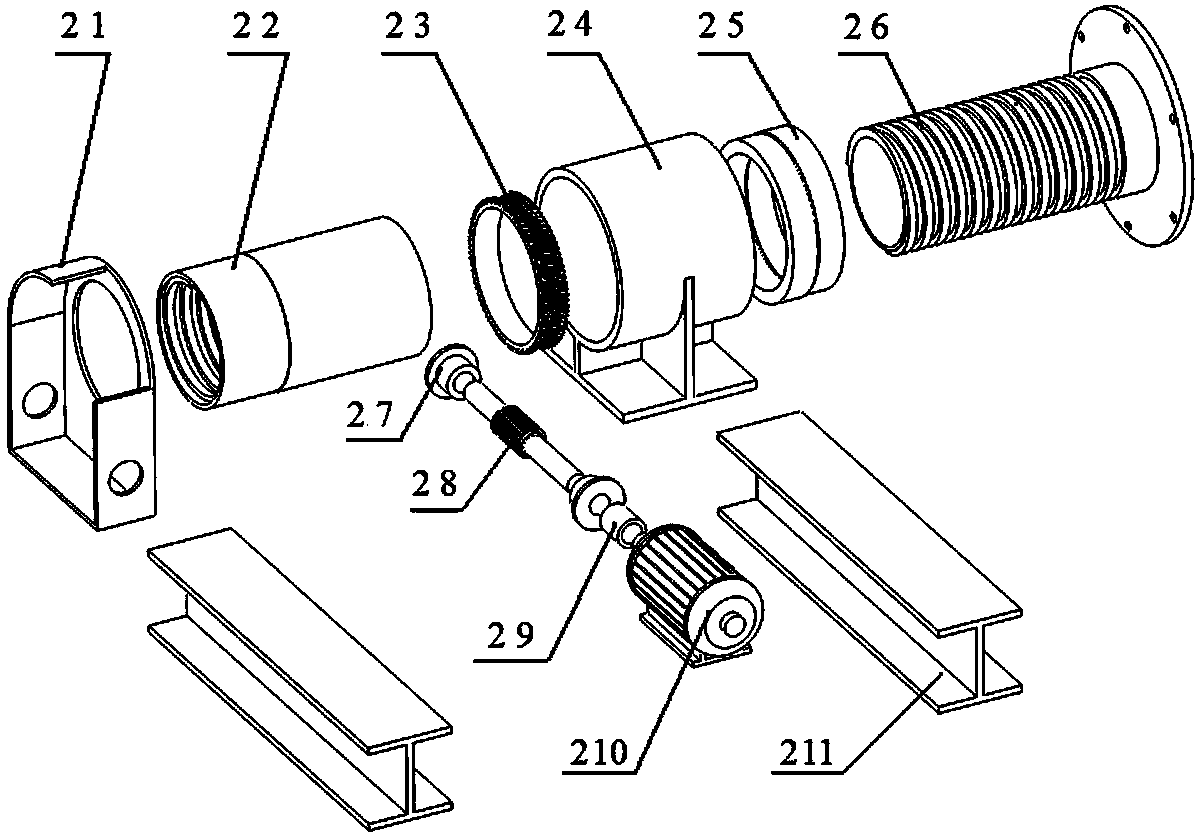

[0027] like figure 2 As shown, the axial propulsion mechanism 2 in the molding equipment adopts a screw transmission mechanism to convert the rotary motion into linear reciprocating motion.

[0028] The drive motor 210 as a power source is mounted on the base 211 and is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com