Solder removal clip

A clip and collet technology, applied in the field of clips with both desoldering and tin absorption functions, can solve the problems of damage to peripheral devices, difficult to pull out smoothly, etc., and achieve the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

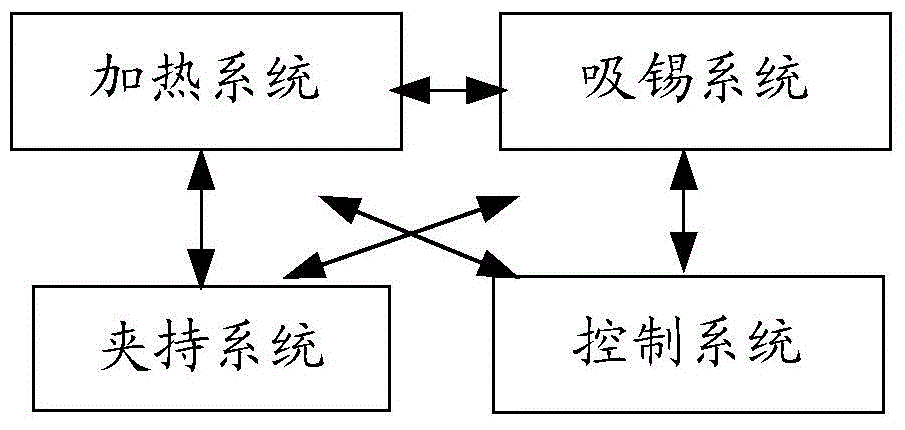

[0020] The core idea of the present invention is to disclose a clip for removing solder and absorbing tin, including a clamping system, a heating system, a tin absorbing system, and a control system, wherein, the clamping system clamps the pins of electrical devices, and the control system controls the heating system Melt the solder on the pins, and at the same time control the tin suction system to suck the melted tin away from the clamping system, realizing the functions of solder removal and tin suction, making the electrical devices easy to disassemble without damaging the surrounding devices; Further, the control system can also independently control the heating system or the tin suction system, so as to realize the independent use of the functions of solder removal and tin suction.

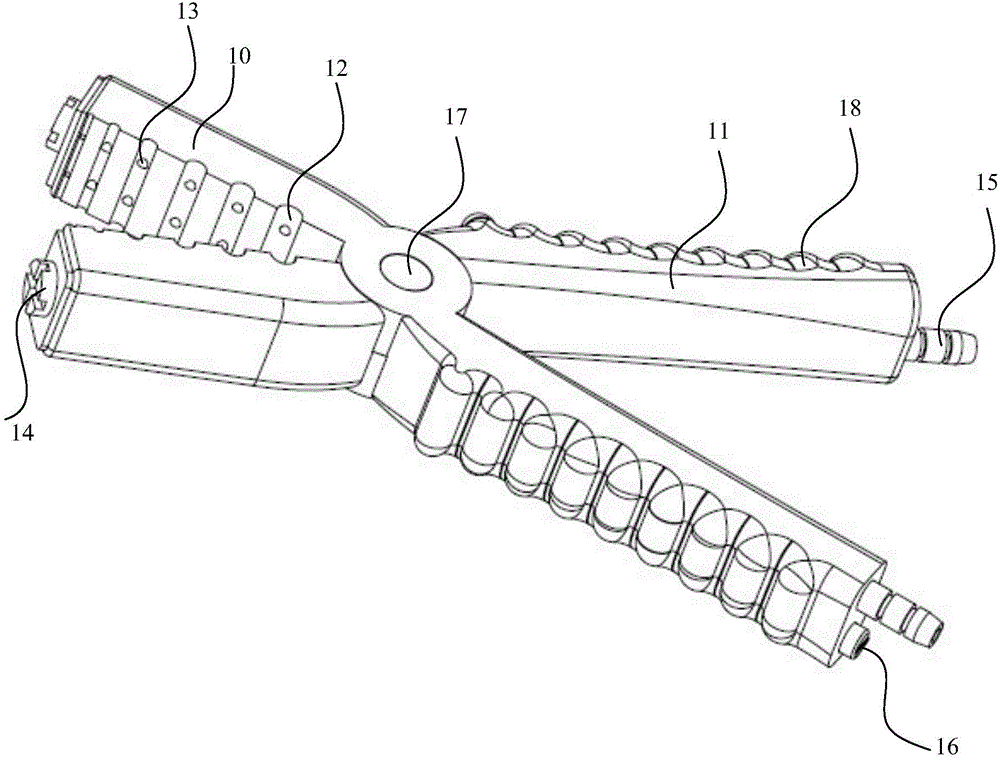

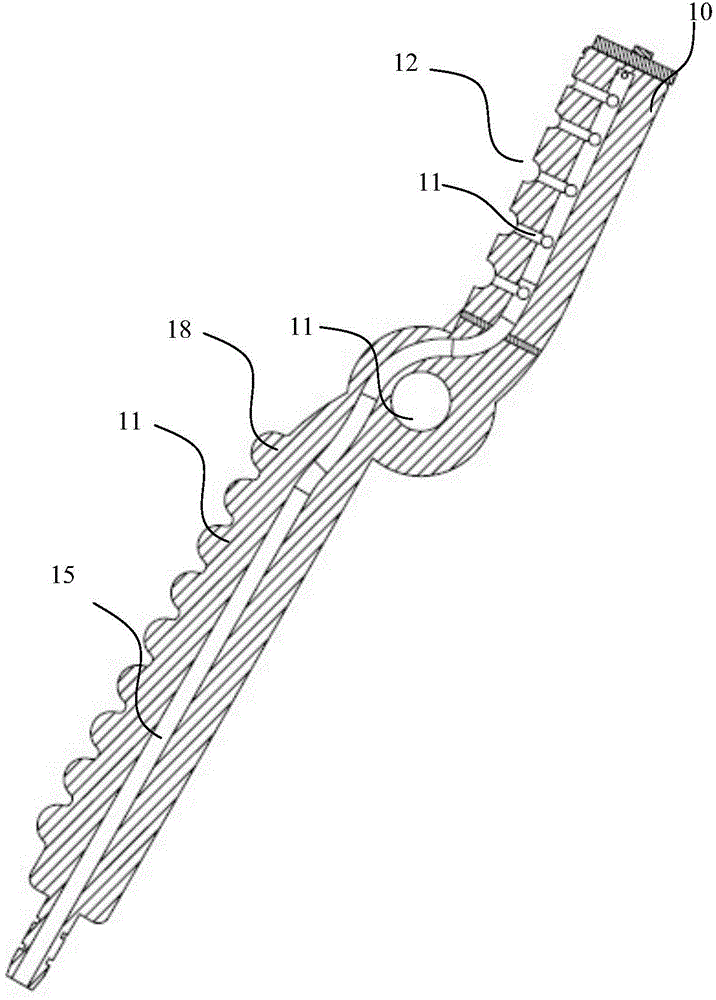

[0021] In order to make the purpose and features of the present invention more obvious and easy to understand, the following will further describe the specific embodiments of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com