Silk screen printing device

A technology of screen printing device and printing table, applied in screen printing machine, printing, printing machine and other directions, can solve the problem of high processing precision, and achieve the effect of reducing resistance, improving economic benefits, and reducing the risk of fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

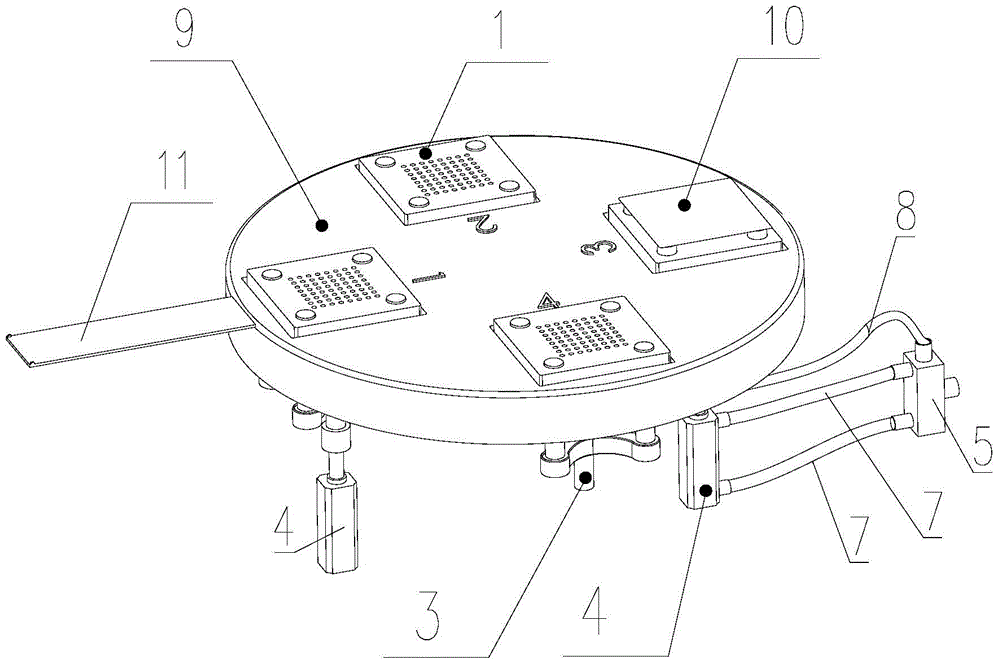

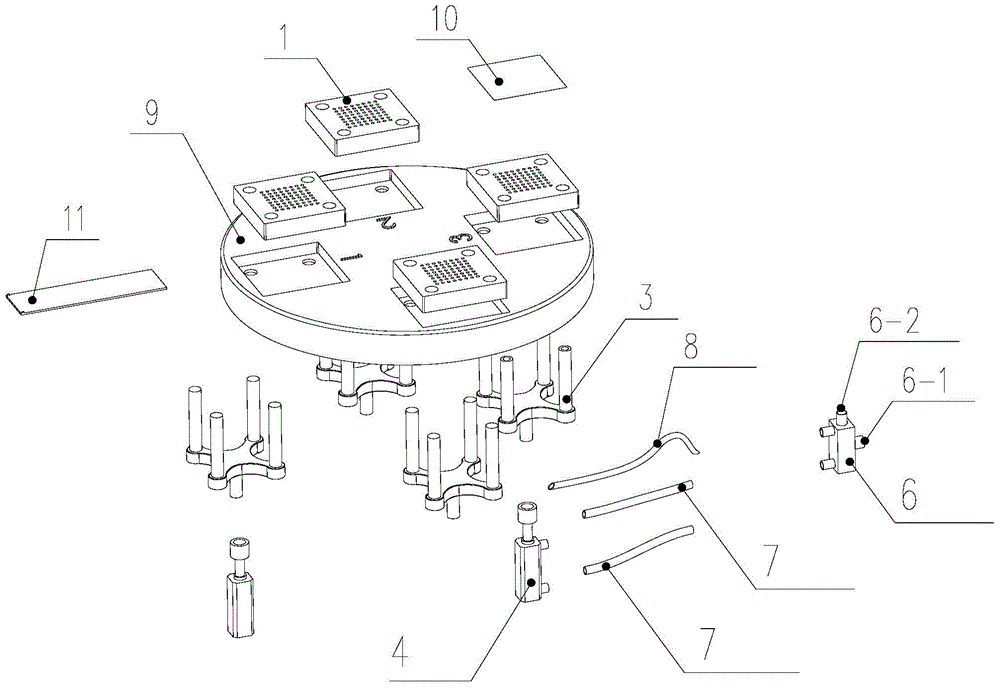

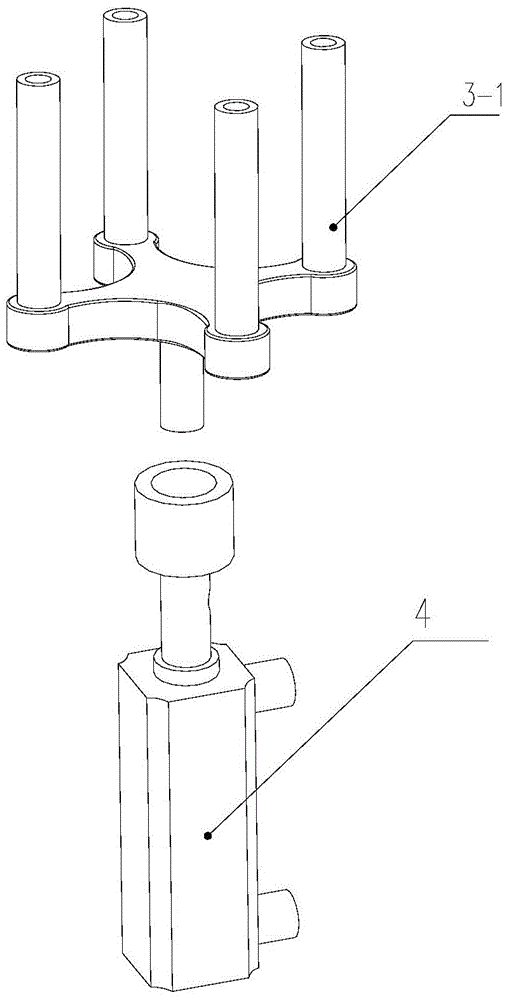

[0019] like figure 1 Shown, a screen printing device, including a rotary platform 9, a printing table 1, a jacking mechanism and an air supply mechanism, the rotary platform 9 has four printing tables 1, each printing table 1 has a supporting jacking mechanism, exist figure 1 The structure of all the jacking mechanisms is not fully shown in the figure. In the jacking mechanism, there is a vacuum breaking air circuit 2 that ventilates to the bottom of the cells on the printing table 1 to break the vacuum. The inlet of the vacuum breaking air circuit 2 is located in the jacking On the lifting moving parts of the mechanism, when the jacking mechanism is in the initial position of the rising top piece, the inlet of the vacuum breaking air circuit 2 is located within the blowing range of the air supply mechanism, and the air supply mechanism starts to blow to the vacuum breaking air circuit in a controlled manner. Into the air, the inlet of the vacuum breaking air circuit breaks a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com