Exposure worktable and exposure device

A workbench and loading technology, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, electrical components, etc., can solve the problem of local vacuum adsorption and keep on the exposure workbench, and achieve high-precision positioning operation and exposure Effects of homework, smooth motion, maintaining positioning accuracy and exposure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

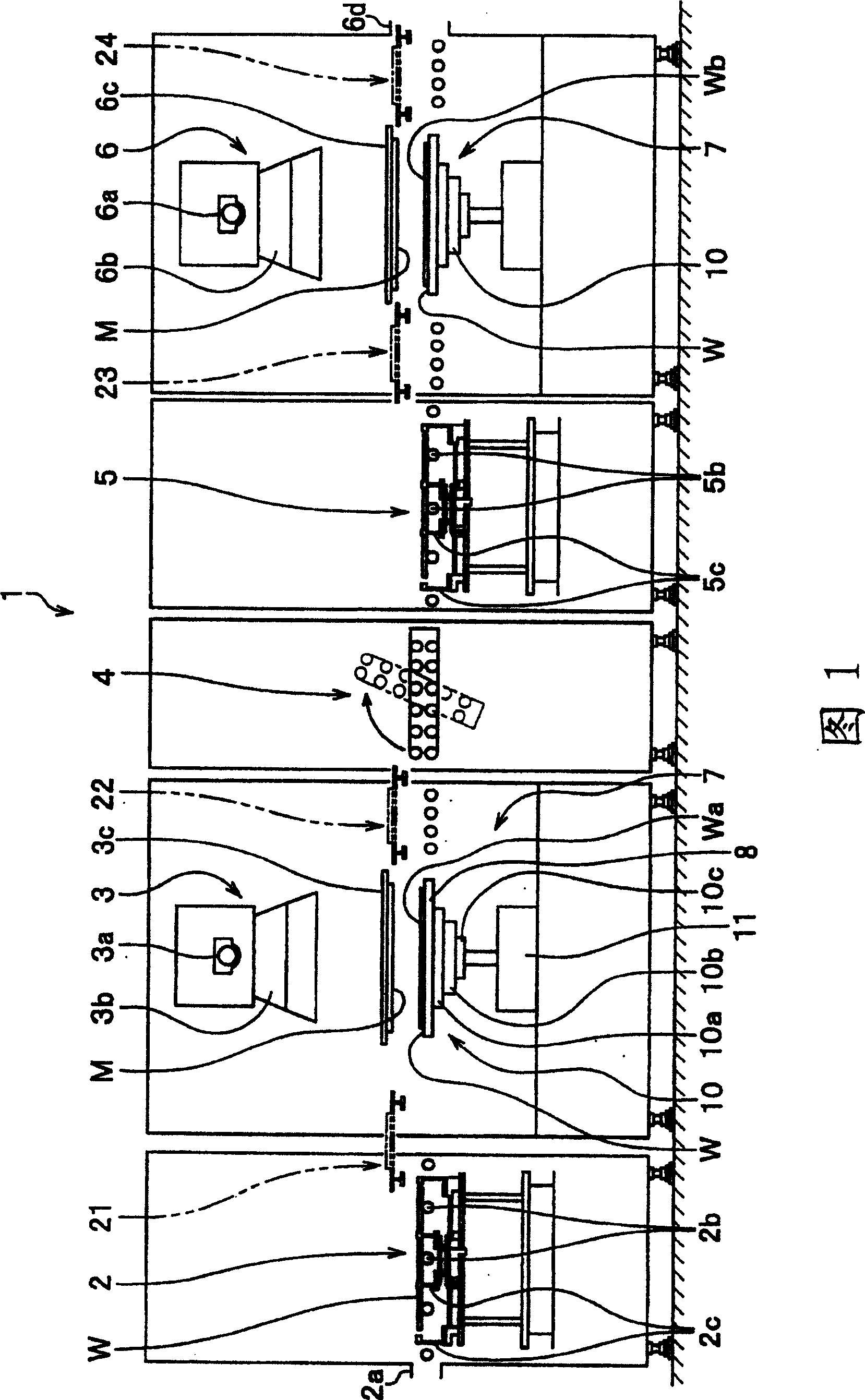

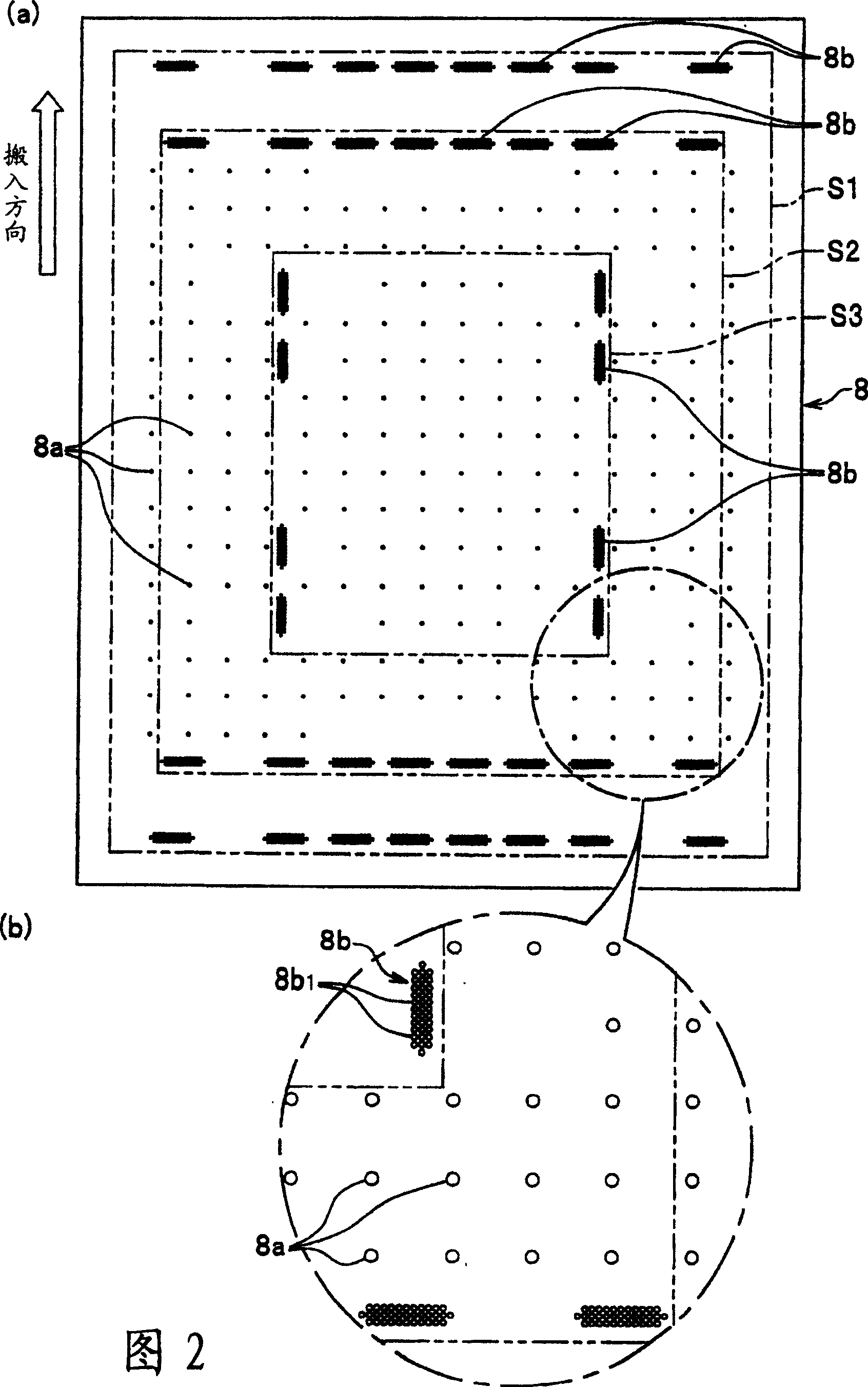

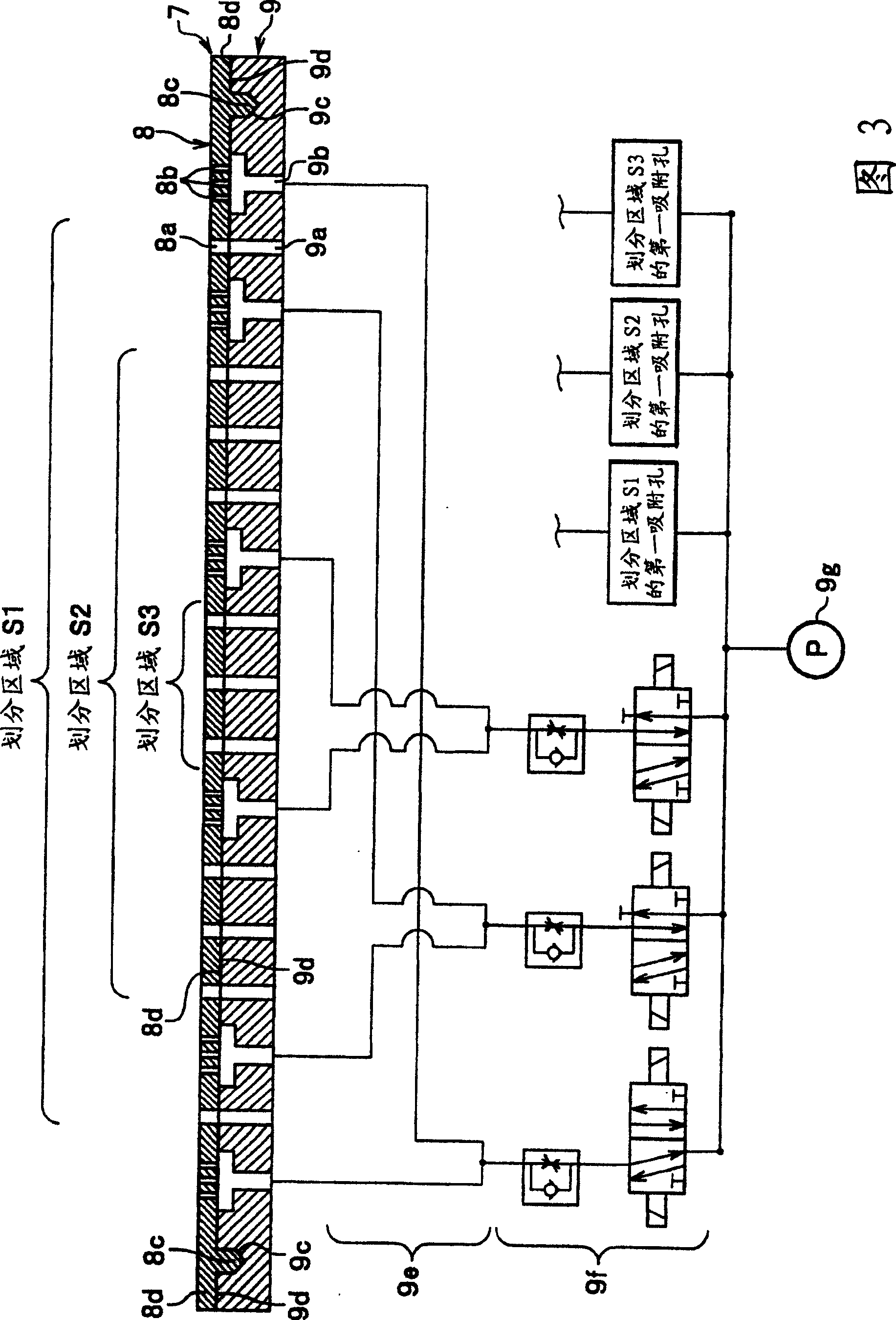

[0045] Hereinafter, best embodiments of an exposure stage and an exposure apparatus for carrying out the present invention will be described with reference to the drawings. In addition, although the exposure apparatus is demonstrated here as an example of the double-sided exposure apparatus which exposes the front surface and the back surface of a board|substrate, of course, it may be the exposure apparatus which exposes one side of a board|substrate. FIG. 1 is a schematic diagram schematically showing the entire exposure apparatus from the side, and FIG. 2 is a plan view of an exposure stage.

[0046] As shown in Figure 1, the exposure device 1 is a device for exposing the surface and the back surface of the substrate W, which includes: a placement mechanism 2 for pre-positioning the substrate W; a surface exposure mechanism 3, which is connected with the placement mechanism 2 adjacently arranged for exposing the surface Wa of the substrate W; an inverting mechanism 4 arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com