Direct-scanning exposure device

An exposure device and direct-drawing technology, applied in the field of direct-drawing exposure devices, can solve the problems of complicated structure, rising device cost, complicated structure of vacuum exhaust, etc., so as to prevent the reduction of exposure precision and the reduction of productivity , Reliable vacuum adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Next, modes (embodiments) for carrying out the invention of the present application will be described.

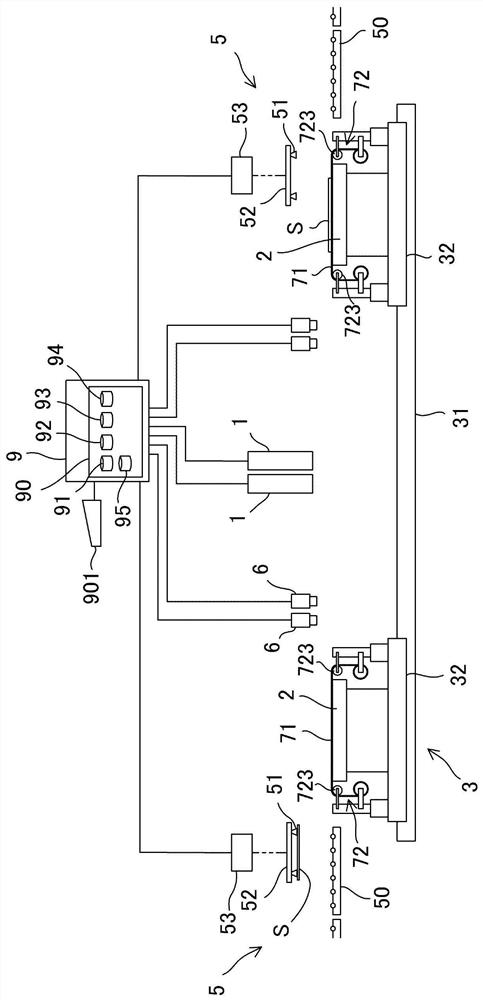

[0065] figure 1 It is a schematic front view of the direct tracing type exposure apparatus of 1st Embodiment. This apparatus is an apparatus for exposing a substrate by irradiating light for an exposure pattern without a mask. Such as figure 1 As shown, the direct drawing exposure apparatus includes: an exposure head 1 for irradiating an exposure area with light for an exposure pattern; a stage 2 on which a substrate S is placed; and a stage 2 on which the substrate S is placed to pass through the exposure area. And the moving handling system3.

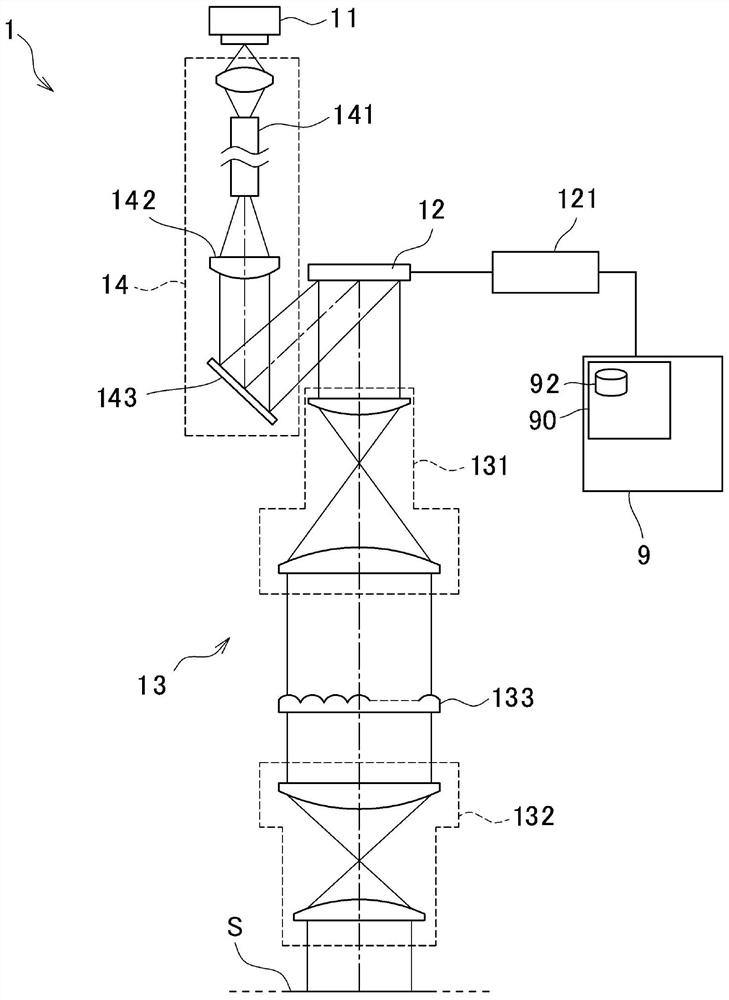

[0066] figure 2 yes figure 1 A schematic diagram of the exposure head 1 mounted on the device. The exposure head 1 has a cylindrical shape as a whole, is arranged in a vertically erected state, and emits light downward. figure 2 It is a schematic diagram showing the internal structure of the exposure head 1 . Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com