Vertical type hydraulic system for waste transfer station transfer vehicle

A technology for waste transfer station and hydraulic system, applied in the field of hydraulic system, can solve the problems of easy loss of wire traction mechanism, complicated operation and control, high maintenance cost, and achieve the effects of compact structure, simple control circuit and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

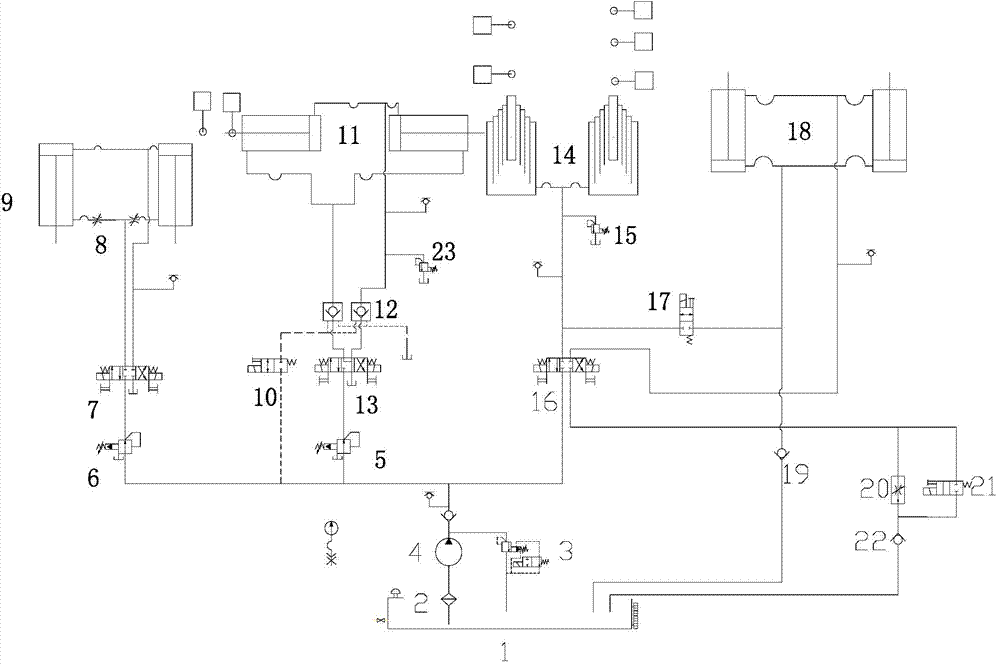

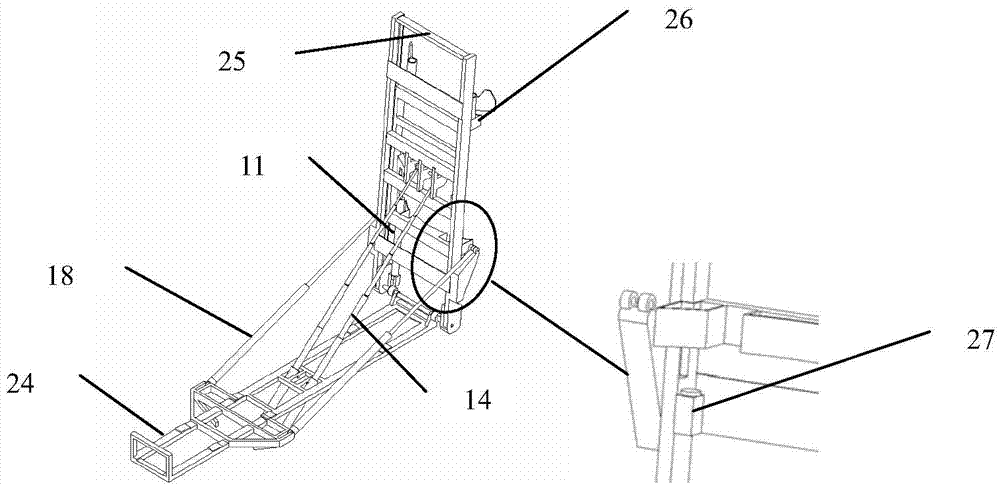

[0019] Specific examples of the present invention are attached figure 1 As shown, it is composed of oil tank 1, filter 2, pilot relief valve 3, hydraulic pump 4, tilting frame lifting oil circuit, tilting frame falling oil circuit, sliding frame moving oil circuit and container door opening or closing oil circuit and Composed of travel switch and hydraulic hose. The lifting oil circuit of the reversing frame includes an O-type functional three-position four-way reversing valve II 16, a safety relief valve I 15, a five-stage single-acting cylinder 14, a two-position two-way reversing valve II 17, and a one-way valve I 19. The hydraulic pump 4 sucks oil from the oil tank 1. At the outlet of the hydraulic pump 4, the pilot relief valve 3 is used to adjust the system pressure. Through the left position of the O-type functional three-position four-way reversing valve II 16, the two-position two-way valve is closed at the same time. Through the reversing valve II 17, the oil only a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com