Paper dividing device and paper dividing method

A technology of paper separation and paper head, which is applied in the direction of pile separation, object separation, transportation and packaging, etc., can solve the problems of high instrument cost, high manufacturing cost of money counting machine, strong pertinence, etc., and achieves low quality requirements and good practical value. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

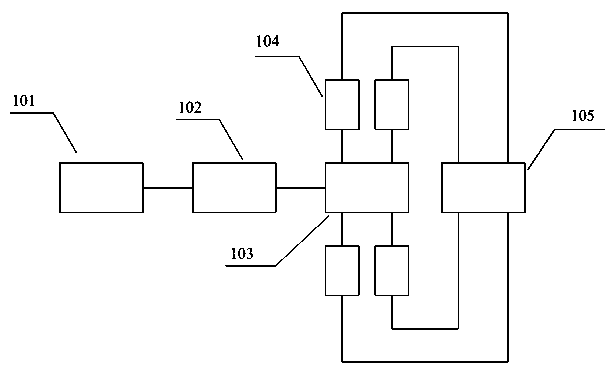

[0023] Such as figure 1 As shown, one embodiment of the present invention is a paper separating device, which includes a motor 101 , a timing belt 102 , a driving wheel 103 , at least one planetary wheel 104 and an air pump 105 .

[0024] The motor drives the drive wheel to rotate through the synchronous belt; for example, the synchronous belt is a belt or a chain. Preferably, the motor is controlled by a controller. Preferably, the paper separating device further includes the controller.

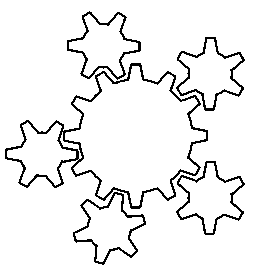

[0025] Such as figure 2 As shown, the driving wheel is set in linkage with at least one of the planetary wheels, and is used to drive at least one of the planetary wheels to rotate when the driving wheel rotates; for example, 3, 4 or 5 of the planetary wheels are set, The driving wheel is arranged in linkage with each planetary wheel, and when the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com