Special steel formwork for combined stairway of high-rise building and assembly method of special steel formwork

A high-rise building and combined technology, which is applied in the processing of building materials, the preparation of building components on site, and construction. It can solve problems such as concrete deformation, affecting the quality of stairs, and difficulty in demoulding, so as to increase firmness and shorten construction. The effect of cycle and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

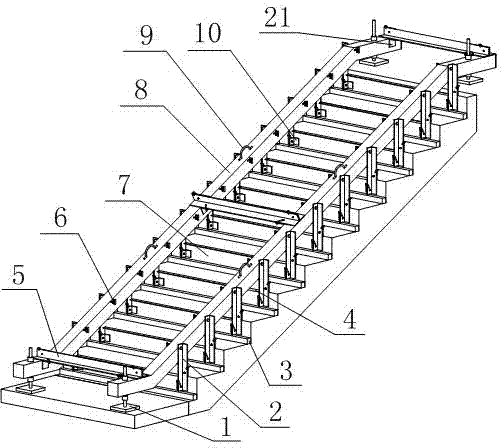

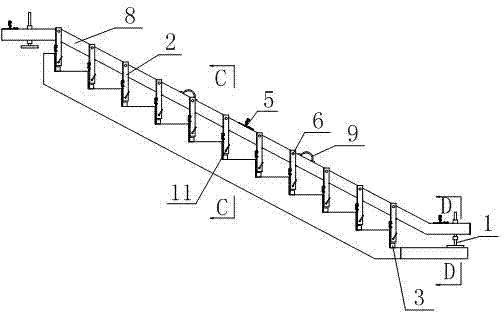

[0031] Such as figure 1 As shown, a steel formwork for combined stairs specially used in high-rise buildings includes two ladder beams 8 parallel to each other, and several horizontal rods 5 are arranged between the ladder beams 8. The ladder beams 8 are vertically connected, and the bottom surface of the horizontal bar 5 is in contact with the top surface of the ladder beams 8. On the side walls of each ladder beam 8, several stepping poles 2 are vertically arranged, and the stepping poles 2 are connected to the ladder beams 8. Fixed, the bottom of the ladder beam 8 is provided with several baffle plates 7, and the two ends of each baffle plate 7 are vertically connected with the stepping poles arranged on different ladder beams 8 respectively, and the baffle plate 7 is parallel to the horizontal bar 5. The ladder beam 8 is made of a hollow rectangular tube. The outer diameter of the rectangular tube 8 is 100mm, and the thickness is 4mm. Under the condition of meeting the str...

Embodiment 2

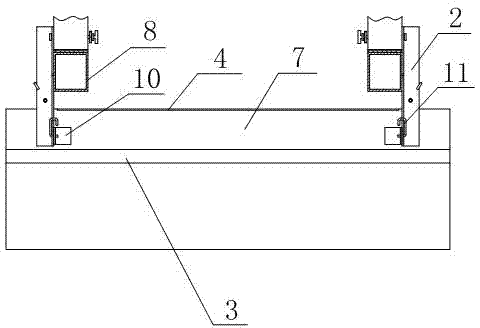

[0033] Such as figure 1 , figure 2 As shown, on the basis of Embodiment 1, the side wall and the bottom surface of the horizontal bar 5 are all provided with an angle steel adapter 21, and one end of the angle steel adapter 21 is respectively connected to the side wall of the horizontal bar 5 or The bottom surface is in contact, the other end is in contact with the ladder beam 8, and the horizontal bar 5 is provided with a buckle 11 in a U-shaped structure. Connector one 21; the outer wall of the step pole 2 is provided with an angle steel adapter two 10, and the angle steel adapter two 10 is in contact with the step pole 2 and the baffle plate at the same time, and the step pole 2 is provided with a U Buckle 11 of type structure, and buckle 11 passes step pole 2 and angle steel adapter two 10 respectively. Angle steel adapter 1 21 and angle steel adapter 2 10 are both made of angle steel, and the widths of their two sides are respectively consistent with the widths of the ...

Embodiment 3

[0035] Such as Figure 5 As shown, on the basis of the above embodiment, horizontal positioning mechanisms 6 are arranged on the opposite surfaces of the two ladder beams 8, and several waist-shaped through holes 20 are arranged on the ladder beams 8, and the horizontal positioning mechanism 6 passes through the waist Type through hole 20 is connected with stepping pole 2 behind. The waist-shaped through hole 20 refers to a through hole whose cross section is an oblong shape. By utilizing the shape of its cross section, the horizontal positioning mechanism 6 can have a space for lateral movement therein, and the lateral movement of the horizontal positioning mechanism 6 is used for stepping. The distance between the uprights 2 can be adjusted in a small range to finally ensure that the distances between the stepping uprights 2 are equal, so that after the concrete is poured, each staircase has the same shape and size.

[0036] The horizontal positioning mechanism 6 includes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com