Method for improving ultrasonic thickness measurement accuracy by using curve fitting

A technology of curve fitting and thickness measurement, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of high precision and unsatisfactory thickness measurement precision, so as to improve the reliability of implementation and reduce the complexity of implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

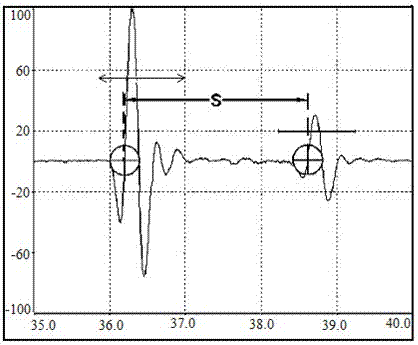

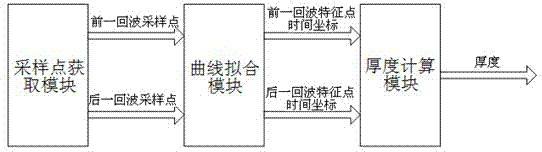

[0032] Use the curve fitting algorithm to calculate the time difference corresponding to the feature points in the two echoes, and multiply the time difference by the sound velocity to obtain the thickness, as shown in figure 2 The schematic diagram of the functional modules in the curve fitting ultrasonic thickness measurement method is shown, including a sampling point acquisition module, a curve fitting module and a thickness calculation module.

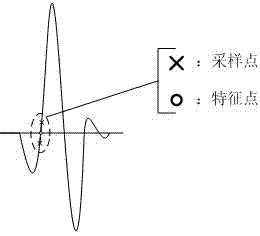

[0033]Since the ultrasonic signal is similar to a straight line within a small period of time (one sampling period) above and below the zero point, and the higher the signal amplitude is, the closer it is to a straight line, so the feature points are selected as the positive maximum peak value or negative maximum peak value of the echo signal. The zero point of the curve fitting algorithm adopts straight line fitting, and the straight line fitting requires two sampling points, which are selected as two sampling points adjacent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com