Self-excited vibration principle-based microstructural fatigue test device

A fatigue test and self-excited vibration technology, which is applied in the field of basic research of micro-nano technology, can solve the problems of high cost, difficult clamping and alignment, insufficient loading load, etc., and achieve the effect of large loading load, low cost, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

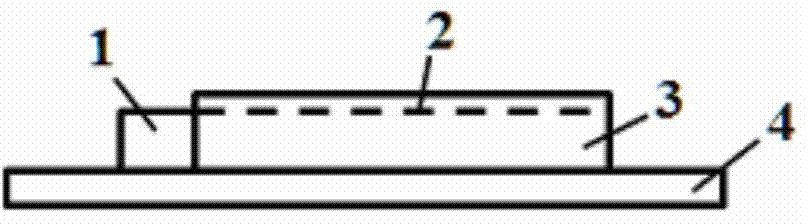

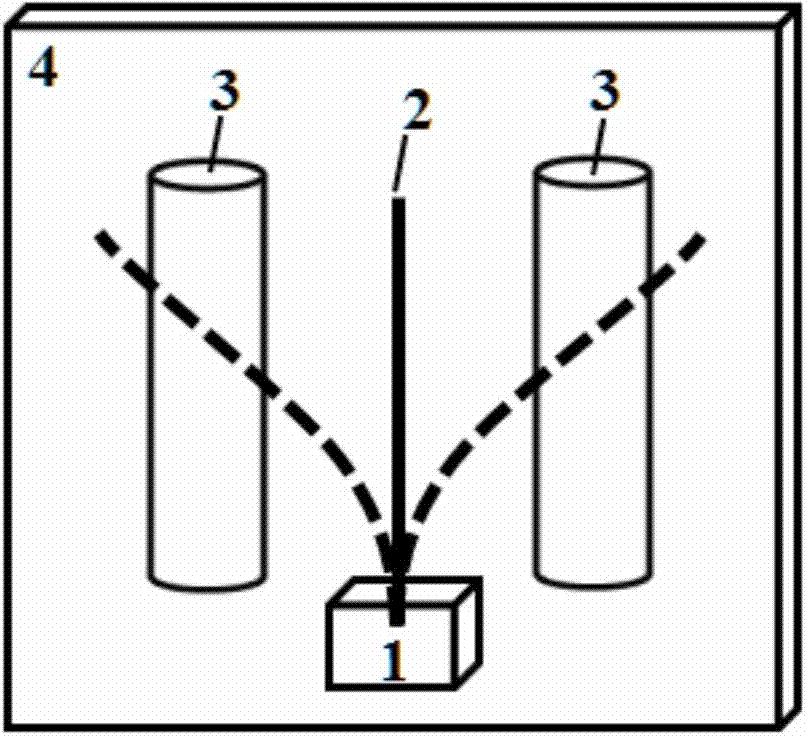

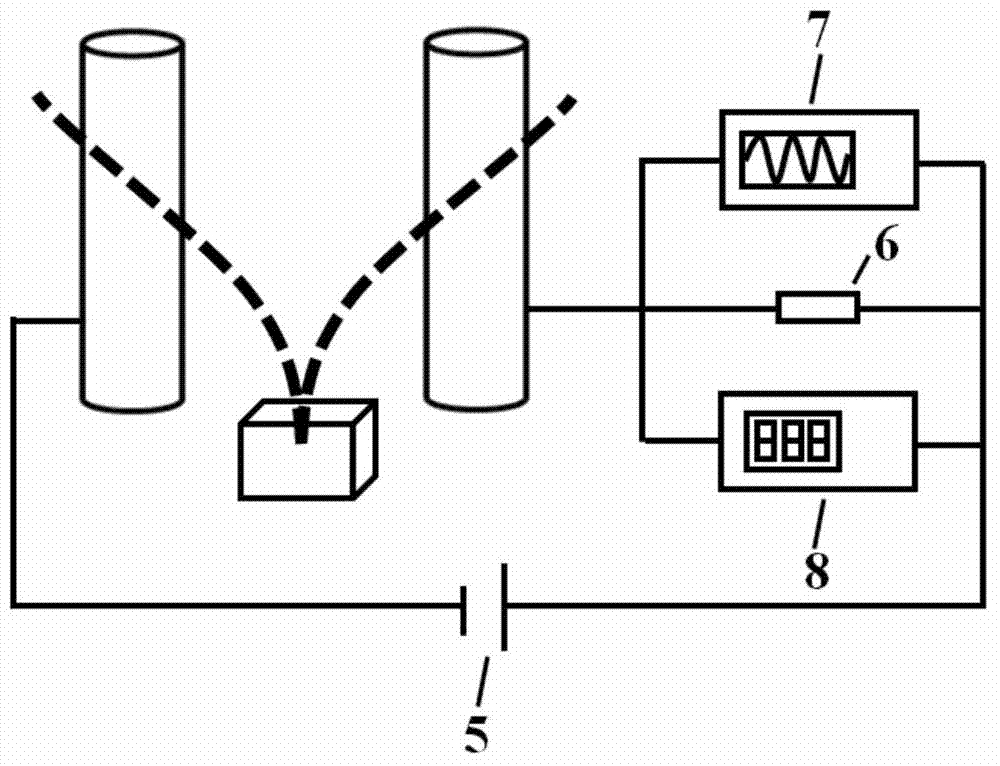

[0030] Such as figure 1 , 2 As shown, the present invention provides a microstructure fatigue test device based on the principle of self-excited vibration, including: an insulating support base 1 (a cuboid in this embodiment, length*width*height is 6mm*3mm*3.3mm), The insulating support base is not connected to any electrode, nor is it grounded, and is in a potential floating state; a conductive micro-specimen 2 (a cylinder in this embodiment, 15-20 mm long, 20-60 μm in diameter), the micro-test One end of the component 2 is fixed on the above-mentioned insulating support base 1, and the other end is suspended horizontally; two DC drive electrodes 3 (in this embodiment, a cylinder with a diameter of 3 mm and a length of 20 mm), the two electrodes 3 and The micro-test pieces are parallel and keep a certain distance (8-10mm), one of the electrodes is connected to a positive DC voltage (0~+3000V), and the other electrode is connected to a negative DC voltage (0~-3000V); The bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com