Process equipment for machining folding key rabbet of automobile

A technology for folding keys and process equipment, which is applied in metal processing equipment, broaching devices, manufacturing tools, etc. It can solve the problems of easy damage to the appearance of keys, long cycle time, and many processes, and achieve good consistency, low cost, and reduced processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

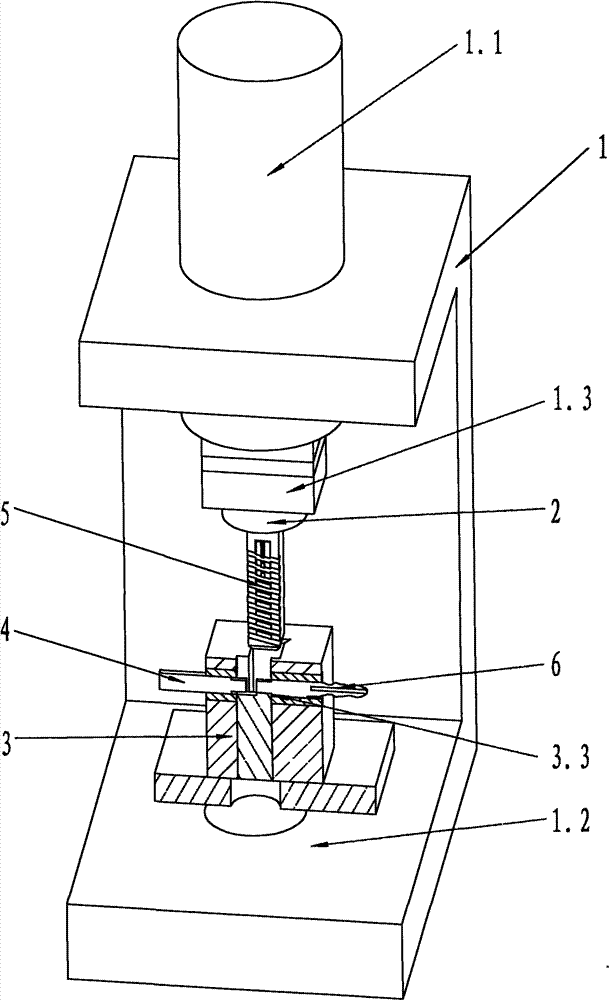

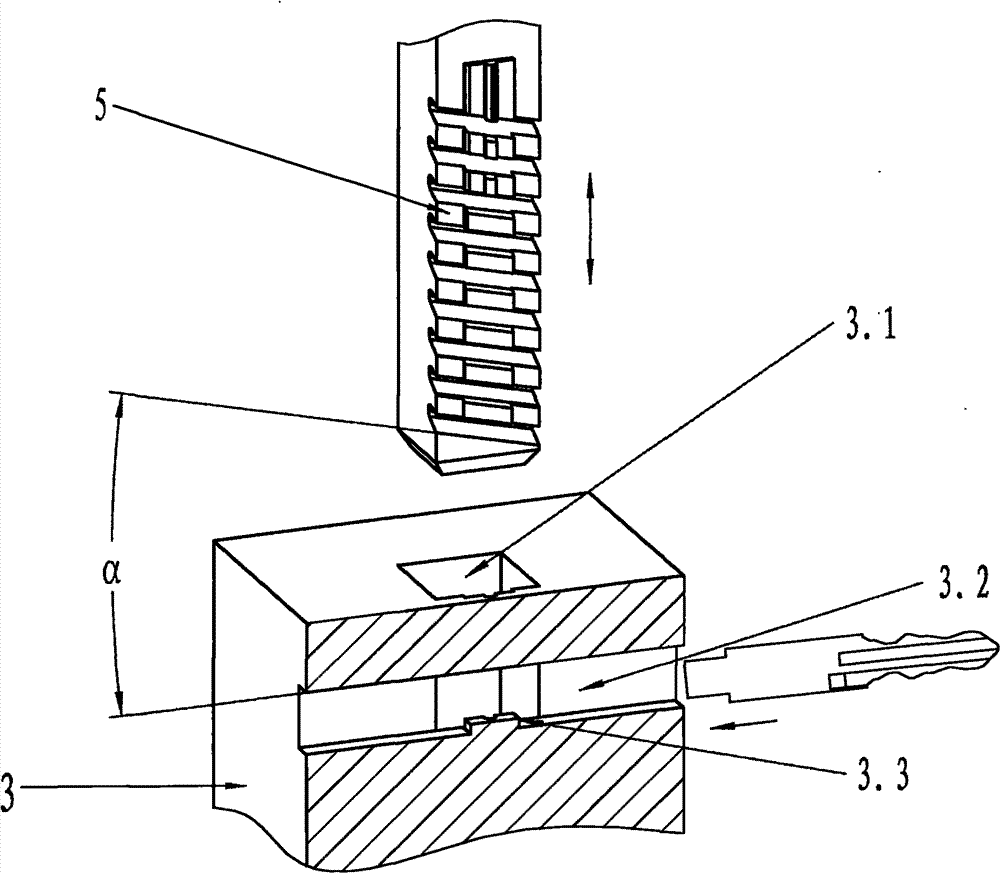

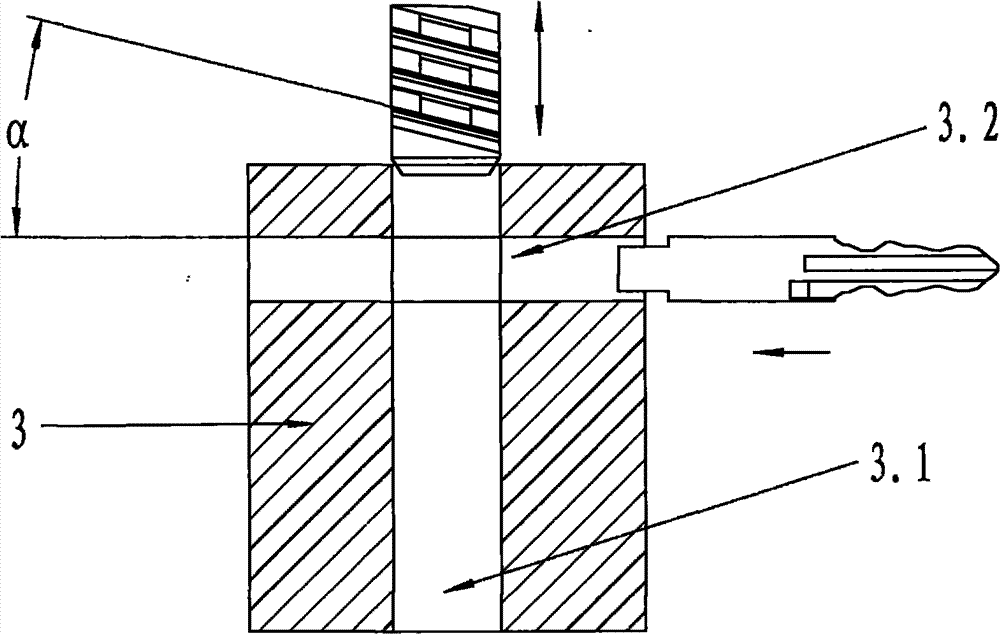

[0051] refer to figure 1 , what the power unit of pressure device 1 of the present invention adopted is air cylinder 1.1, and pressure device 1 in reality also adopts small-sized pneumatic press machine, also satisfies the requirement. The push knife 5 is fixed by the knife clamping part 1.3, and the rubber pad 2 is also housed under the knife clamping part 1.3. The clamp 3 is installed on the base 1.2, the key 6 is inserted, and the tenon step is pushed to lean against the positioning boss 3.3 of the clamp. Then start the power unit 1.1 again, and the push knife 5 moves down until the rubber pad 2 and the clamp 3 touch the limit, and the cutting of the push knife is just completed at this time. After finishing the cutting process, since the key 6 is squeezed due to unilateral cutting, the key 6 should not be taken out manually. The stripping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com