Continuous type chemical equipment and method and device for evaluating performance of control loops thereof in real time

A control loop and continuous technology, applied in the chemical industry, can solve problems such as the inability to complete systematic calculation and diagnosis reports, and achieve the effect of avoiding the decline in production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes the embodiments of the present invention in detail, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

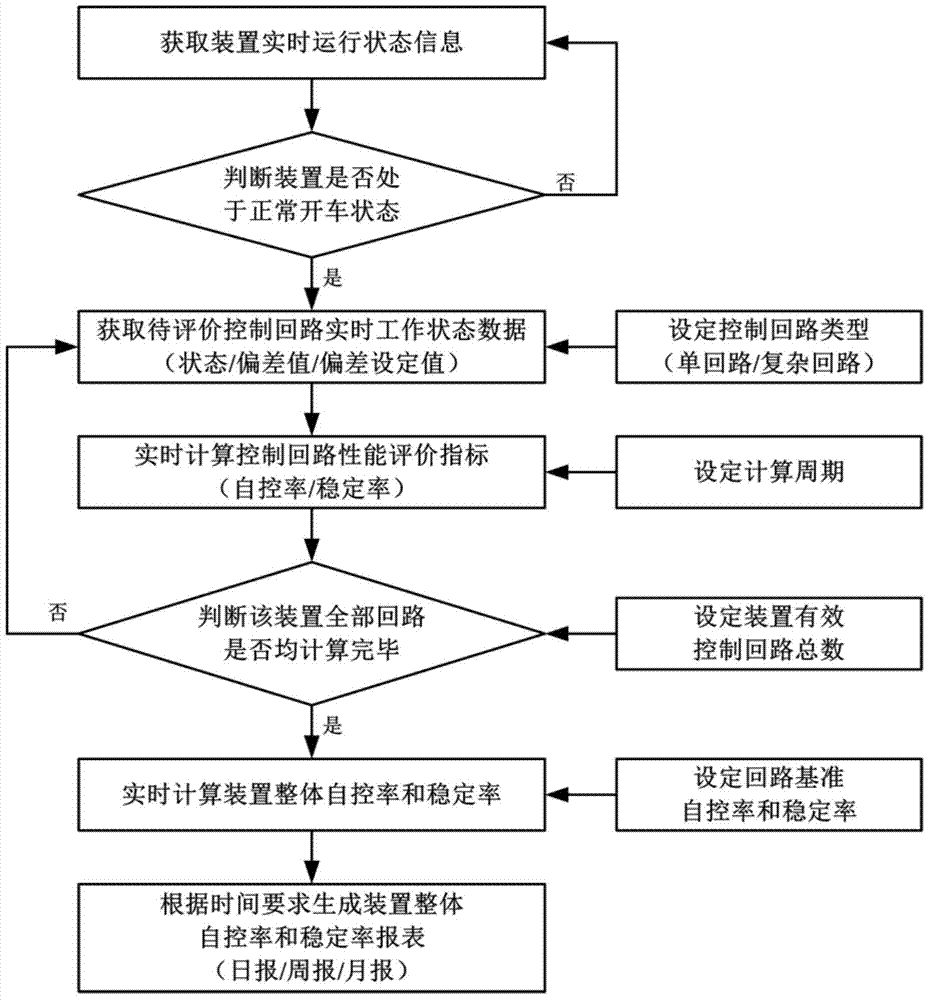

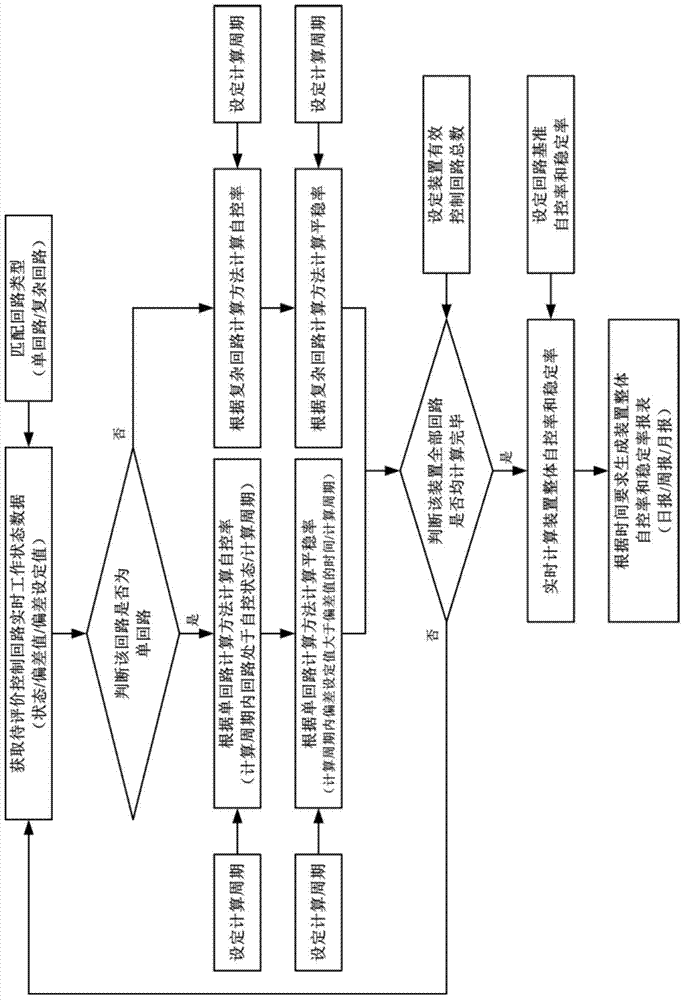

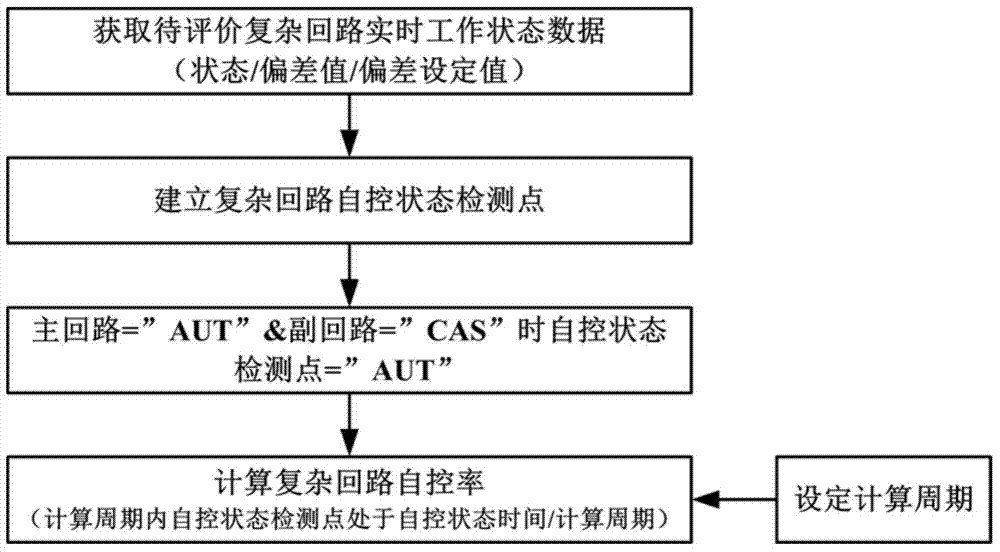

[0021] The invention is based on the real-time operating status information of the continuous chemical plant. Firstly, it is judged whether the chemical plant is in a normal driving state; secondly, the real-time working status, deviation value and deviation setting value of each control loop of the chemical plant are obtained. In this way, according to the different types of control loops (for example, single loop and complex loop), the performance evaluation index can be calculated in real time within the set calculation period. When the performance evaluation index of all control loops in the complete chemical plant is calculated online , Obtain the automatic commissioning rate and working stability rate of the control loop of the chemical plant at the current moment, so as to conduct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com